Over the past few years, the Army's process for effectively and efficiently generating trained and ready forces for combatant commanders has shifted from the Army Force Generation (ARFORGEN) model to Sustainable Readiness. ARFORGEN focused units on building readiness for known missions and relatively short deployments.

The ARFORGEN model included a programmed reset on the back end of each deployment cycle. The readiness "cliff" that resulted meant that entire formations were unavailable for contingencies when they returned to home station. ARFORGEN was an effective approach under different conditions, but it had to be replaced in practice and in mindset by Sustainable Readiness. Focusing solely on the next assigned unit mission is no longer good enough.

Sustainable Readiness focuses manning, training, and equipping efforts to enable commanders to maintain acceptable readiness levels at all times. We have to reduce the readiness peaks and valleys so that we are ready now to mitigate the risk that accompanies the uncertainty of our environment. We need to be prepared to fight and win our nation's wars when called upon.

The overarching philosophy of Sustainable Readiness is that leaders at all levels will build and sustain readiness at all times, otherwise unit readiness will suffer. From a sustainment standpoint, this fundamental change in the way we manage readiness places greater demand on materiel management at the tactical level. This article addresses key insights of maintenance and supply management that are required to sustain a combat-ready, globally responsive force that is ready now.

MAINTENANCE MANAGEMENT

Commanders are responsible for maintaining their equipment to standard at home station, during combat training center training, and while deployed. However, based on observations and trends depicted in data on monthly reports from the Army Maintenance Status System, units are struggling to achieve operational readiness goals. Frankly, units must improve organizational maintenance and the management of operational fleet readiness.

Army Regulation 750-1, Maintenance of Supplies and Equipment, is the regulatory document used to establish maintenance policies and should also be used to guide maintenance programs within all formations. Obviously, the bottom line is that maintenance lets units generate and regenerate combat power to enable training and mission accomplishment.

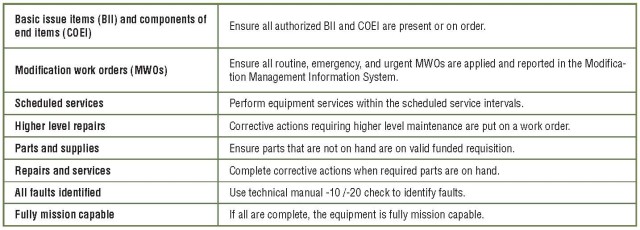

Equipment is considered operationally ready if it is determined to be fully mission capable in accordance with the standards prescribed in the applicable 10- and 20-series technical manuals (TMs). The Army TM-10/-20 maintenance standard is the only standard for maintaining equipment. It is paramount that units adhere to this standard to ensure fleet readiness. (See figure 1.)

Another critical element for achieving fleet readiness is teaching operators and crews how to maintain their equipment. Commanders must train their leaders and Soldiers to perform preventive maintenance checks and services and scheduled services on their equipment and qualify them on the performance of these skills, no differently than how a Soldier qualifies on a weapon system.

Commanders must allocate time in training schedules and focus manpower resources on maintenance to make this work. We absolutely must re-educate leaders on how to manage organizational maintenance.

Examples of maintenance systems that require oversight at the tactical level include command motor stables, routine executive officer maintenance meetings at the company and battalion levels, and weekly equipment status report reviews by the brigade combat team executive officer or the brigade support battalion commander. Other examples are maintenance terrain walks and monthly materiel readiness reviews hosted by the division deputy commanding general for sustainment or a similar representative.

Equally important is the ability of the Army's maintenance technicians and noncommissioned officers to execute advanced diagnostics on combat platforms. An article by M.C. "Steve" Cherry in the May-June 2017 edition of Army Sustainment highlighted two programs that tactical and operational leaders can use to narrow the gap in the institutional knowledge and experience of our senior maintainers.

The first program is the Unit Diagnostics Immersion Program (UDIP). The UDIP consists of a mobile training team composed of instructors from the Combined Arms Support Command that visits Forces Command (FORSCOM) installations to provide hands-on training using unit tools, test equipment, vehicles, and facilities.

The second program is the Master Diagnostician Training Initiative conducted at the National Guard Sustainment Training Center at Camp Dodge, Iowa. Master diagnostician training focuses on the "why" of diagnostics and troubleshooting and builds on the critical thinking skills and proficiency required to isolate faults and repair vehicles.

The major difference between the two programs is the location: home station versus Camp Dodge. The intent of both programs is to provide maintainers with the knowledge needed to rapidly diagnose problems and provide cost-effective solutions so that units can reach higher levels of readiness.

SUPPLY MANAGEMENT

To reiterate what has been said by countless leaders before me, disciplined maintenance programs require disciplined supply operations. Disciplined supply operations include the management of authorized stockage lists (ASLs), shop stocks, and bench stocks. Ensuring disciplined demand at the unit level drives readiness throughout the Army's organic industrial base.

Disciplined demand drives down customer wait time and drives up the operational readiness of our combat fleets. At the tactical level, we must protect precious operation and maintenance dollars by validating class IX (repair parts) requirements, cross-leveling excess stock to fill shortages, and imposing logistics policies that prevent waste.

Army Regulation 710-2, Supply Policy Below the National Level, and Army Regulation 735-5, Property Accountability, lay out the objectives and expectations that commanders should use to guide their supply programs. The bottom line is that getting our ASLs and shop stocks at the right breadth and depth increases our mobility and ability to rapidly deploy, ensuring we are ready now. The right breadth and depth also allows combat formations to function in an expeditionary environment for extended periods of time.

A second supply management topic is that of the supply level or the equipment on hand (EOH). The supply level is a key indicator of unit readiness and is a comparison of the EOH to wartime or primary mission requirements.

Without the right equipment, tactical formations are at risk of not meeting their assigned missions. A trend that I have witnessed across FORSCOM formations is that excess equipment affects the supply level simply because equipment is not in the right formation. I have also observed that when units turn in excess and align their property books, EOH levels increase.

The buildup of excess did not happen overnight; it occurred as a result of multiple deployments, units receiving unauthorized and rapidly fielded equipment for directed missions, equipment modernizations, new equipment fieldings, multiple organizational changes, and some undisciplined supply practices both while deployed and at home station.

Holistically, the sustainment enterprise is working diligently to maximize EOH and eliminate actions that generate excess. For instance, before new equipment is fielded, a disposition plan for legacy equipment must be in place. The disposition plan relieves the burden on the unit and commander to maintain two sets of equipment.

The goal is to unburden Soldiers and commanders so that they can focus on training and mission requirements. That being said, the best way for commanders to reduce excess is to ensure EOH matches authorization documents and that a disciplined supply program is in place to address all components of property accountability.

SUPPORTING SYSTEMS

The last area that I want to briefly touch on is the use of logistics information systems to influence both maintenance and supply operations. By now, most leaders know that Global Combat Support System-Army (GCSS-Army) is a tactical unit and installation logistics information system that is linked to the General Fund Enterprise Business System.

GCSS-Army replaces the existing suite of legacy standard Army management information systems, including the Standard Army Retail Supply System, the Standard Army Maintenance System-Enhanced, Property Book Unit Supply Enhanced, and their associated financial management information systems.

GCSS-Army tracks supplies, spare parts, and organizational equipment. The system affects every supply room, motor pool, direct support repair shop, warehouse, and property book office. When fully deployed, GCSS-Army will produce timely, precise, and effective information needed by the warfighter in order to move, track, maintain, and account for equipment and supplies.

GCSS-Army will integrate tactical logistics enterprise information for leaders and decision-makers in order to provide a single picture for maneuver and sustainment that they will use to manage combat power. Success will be gained from GCSS-Army only if each echelon, from the operator to commander, knows its role and functionality.

I am hearing from the field that proficiency comes with use, more use, training, and more training. Setting aside time, maybe multiple times, is vitally important in order to ensure Soldiers and leaders can effectively operate and manage GCSS-Army's functions and management tools. We cannot afford not to maximize the system's capabilities.

Commanders at all echelons must understand the new dynamic environment that comes with Sustainable Readiness and the difference between rotational and surge operations. Leaders must embrace all aspects of materiel management in order to maximize unit readiness.

Maintenance and supply programs are not just logistics programs; leaders must understand and enforce these programs throughout their formations in order to sustain the momentum gained in the past year and to ensure formations are ready to "Fight Tonight" if called upon.

--------------------

Maj. Gen. Ronald Kirklin is the FORSCOM G-4. Headquartered at Fort Bragg, North Carolina, FORSCOM provides training and readiness oversight for more than 750,000 active duty and reserve component Soldiers.

--------------------

This article was published in the November-December 2017 issue of Army Sustainment magazine.

Social Sharing