ADELPHI, Md. -- Army and MIT researchers advanced a unique experimental device to better test the durability of high performance and robust polymeric materials that appear to strengthen themselves under attack by rapid impact.

The Army Research Laboratory's Dr. Alex Hsieh, along with Prof. Keith A. Nelson, Dr. David Veysset and Dr. Steven Kooi, from the Army's Institute for Soldier Nanotechnology at MIT, discovered that when targets made of poly(urethane urea) elastomers, or PUUs, are impacted at very high speed by micro-particles made of silica, the PUU target shows hyperelastic behavior. That is, they become extremely stiff when deformed at strain rates on the order of 108/s, which means roughly that the material of the target deforms to half of its original thickness in an extremely short time equal to one second divided by hundred millions. PUUs also bounce back after the impact, Hsieh said.

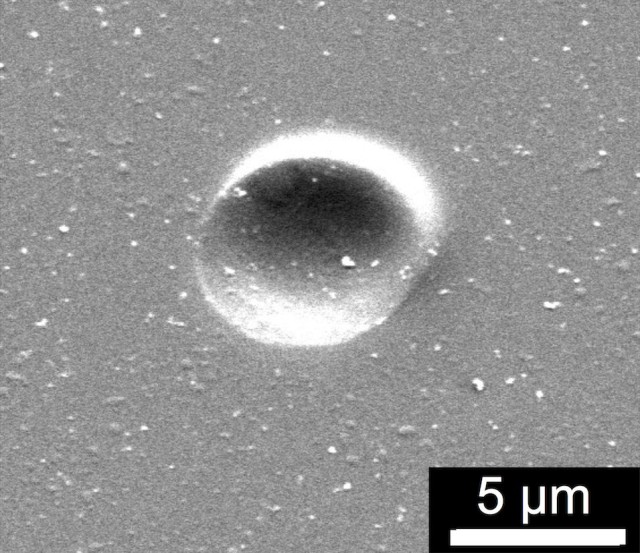

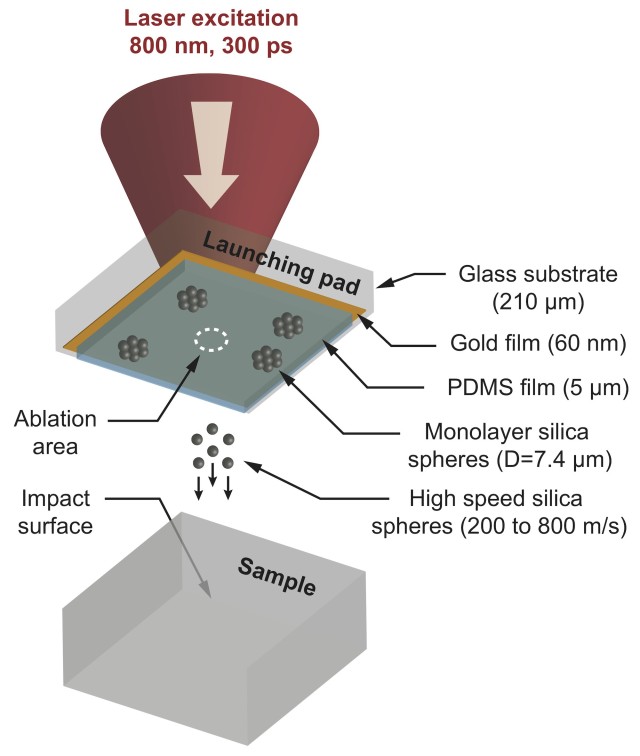

The test device uses a pulsed laser to shoot micrometer-sized bullets at targets made of PUUs. Researchers found, for the first time, "behaviors that contrast greatly to the impact response observed in a cross-linked polydimethylsiloxane elastomer where micro-particles penetrated the target and the target material did not bounce back or completely recover."

Scientists say their discovery on bulk elastomers can help design matrix materials for composites for the future generation of U.S. Army combat helmets. The Army's enhanced combat helmet uses high performance ultrahigh molecular weight polyethylene, or UHMWPE, fibers based composites. These fibers have high breaking strength, per unit cross section area, about fifteen times stronger than steel but are flexible like fabrics.

Traditional armor material designs include ceramics, metals and lightweight fiber reinforced composites for both Soldier and vehicle protection, which are typically based on stiffness, the resistance of a material against deformation, toughness, the ability to absorb energy and plastically deform prior to fracture.

But from the materials science perspective, these standard bulk metrics alone are not sufficient to quantify how fast molecules in a polymer solid can change their mobility with respect to the rate of deformation, nor the propensity towards a change of their respective physical state during dynamic deformation -- i.e. could elastomers change from rubber-like to glass-like when they are deformed at increasing high rates?

Hsieh said the team focused on polymers, which are made up of a very large number of small molecular units that are strung together to form very long chains, which can be well organized or randomly packed. Specifically, polymeric materials that are strong like impact-resistant safety glasses or flexible like rubbers. Elastomers are a class of manmade rubbers, which can be synthesized from a broad range of polymer chemistries.

"They generally have low Young's modulus which means low resistance to elastic deformation under loading at ambient conditions, and higher failure strain -- the capability to sustain significantly greater amount of strain before failure -- than most of the plastic materials," he explained.

To further validate the molecular influence, the team has conducted comprehensive studies on PUUs along with a glassy polycarbonate. While polycarbonate is known for its high fracture toughness and ballistic strength, these PUUs, regardless of their respective composition, exhibited greater dynamic stiffening during impact at strain rates on the order of 108/s. Furthermore, the resistance against penetration of the micro-particle can be optimized, i.e. a ~ 50 percent reduction in the average maximum depth of penetration was achieved by simply varying the molecular composition of PUUs.

"This is very exciting," Hsieh said. "Seeing is believing. New understanding from these research discoveries -- the essence of hyperelastic phenomenon in bulk elastomers, particularly at the moment of target/impulse interaction, strongly points out to be a plausible pathway key to manipulating failure physics and towards a new design paradigm for robust materials."

PUUs are known to have complex microstructure along with a broad range of relaxation times -- the characteristics that are used to reflect the efficiency how molecules in polymer chains respond to an external impulse. Specifically, for PUUs molecules with longer relaxation times on the order of microseconds at ambient conditions, e.g., slower dynamics, enabling dynamic stiffening, while those with nanosecond relaxation times at ambient conditions were capable of providing additional energy absorption towards dynamic strengthening. These viscoelastic characteristics show that elastomers as well as other polymeric materials may deform in different fashions depending strongly on how fast it is being deformed.

The team hypothesized that a cooperative molecular relaxation mechanism resembling a resonance phenomenon of "chainmail-like" molecular motions each oscillating at specific frequencies to dissipate absorbed energy. These dynamic strengthening and stiffening characteristics could presumably be facilitated by intermolecular hydrogen bonding present throughout the physically-crosslinked network in PUUs. In contrast, the microsecond relaxation at ambient conditions is not present in polycarbonate nor are hydrogen bonding and the corresponding enabling molecular mechanism available at all in polycarbonate, despite its toughness and impact strength. Thus, PUUs or high performance elastomers with multiple relaxation times are greatly desired and key to enabling both the dynamic strengthening and dynamic stiffening over the temporal scale from microseconds to nanoseconds.

These unique observations were elaborated in a recently published paper in Polymer, 123 (2017) 30-38, http://dx.doi.org/10.1016/j.polymer.2017.06.071.

Meanwhile, materials like polyurethane, similar to PUU, as matrix elastomers performed better against backface deformation found in lightweight UHMWPE composites. This is essentially the buckling of material inside combat helmets that transfer large forces to the skull and cause blunt impact trauma. PUUs, polyurethanes and similar elastomers, Hsieh said, that exhibit dynamic strengthening in high-rate deformations and reduce significantly the deformation of the helmet under impact, for integration with state of the art fibers, can be of great benefit to future combat helmets.

In addition to combat helmets, other potential applications of robust high performance elastomers for Soldier protection include but are not limited to transparent face shields, mandible face shields, ballistic vests, extremity protective gear, and blast-resistant combat boots.

It is also envisioned that this research discovery on hyperelastic phenomenon of PUUs, particularly at the moment of very high speed impact, also crosses into foreseeable realms such as protection of professional football players and young athletes against concussions or any other brain-related injuries brought upon by collisions. From the materials design perspective, high performance robust elastomers can be utilized as the outermost layers of the helmet or to simply replace the polycarbonate shell, Hsieh said.

-----

The U.S. Army Research Laboratory, currently celebrating 25 years of excellence in Army science and technology, is part of the U.S. Army Research, Development and Engineering Command, which has the mission to provide innovative research, development and engineering to produce capabilities that provide decisive overmatch to the Army against the complexities of the current and future operating environments in support of the joint warfighter and the nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing