ABERDEEN PROVING GROUND, Md. (September 20, 2017) - The Army's Global Response Force, or GRF, will soon possess a real-time, in-flight mission planning and situational awareness capability for generals and their staff, thanks to a government-to-government partnership that is streamlining the design-to-delivery process.

The Command And Staff Palletized Airborne Node, or CASPAN, is part of the Enroute Mission Command, or EMC, capability, which allows forces onboard Air Force C-17 aircraft to collaborate with other airborne and ground forces for early entry and forcible missions. It includes network and voice connectivity -- plus live video derived from unmanned aerial vehicles -- to give leaders a view of the drop zone and enable continuous mission command right up to the jump.

"EMC will enable these critical early entry forces to be better prepared and to adjust their courses of action as needed prior to combating peer and near-peer adversaries on the ground," said Lt. Col. Mark Henderson, product manager for Network Modernization, or PdM NetMod, which manages EMC for the Army. PdM NetMod is assigned to the Program Executive Office for Command, Control, Communications-Tactical, or PEO C3T.

PdM NetMod has partnered with the U.S. Army Materiel Command's Communications-Electronics Research, Development and Engineering Center, or CERDEC, to design and integrate the CASPAN, which joined earlier EMC node deliveries from CERDEC that included custom transit cases and an Internet-ready workspace for paratroopers and their laptops.

CERDEC engineers and technicians performed the work at CERDEC's Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance Prototype Integration Facility, or C4ISR PIF.

"As we did with the initial EMC operational capability, we turned to the CERDEC C4ISR PIF for innovative engineering and design options that would help us deliver the CASPAN's critical capabilities to the GRF," said Lt. Col. Mark Henderson, product manager for Product Manager Network Modernization, or PdM NetMod, which manages EMC for the Army. "They accomplished all that we asked rapidly while facing a very aggressive turn-around schedule to meet the GRF's mission needs."

CERDEC's C4ISR PIF provides engineering design, development, fabrication, installation, integration and fielding support for Soldier prototype C4ISR systems, including shelters, vehicles, aircraft, and watercraft.

"We design and produce prototypes at a low-rate production for initial evaluation or first-year fielding to help the Army validate its state-of-the art capabilities," said James Sroczynski, C4ISR PIF chief engineer.

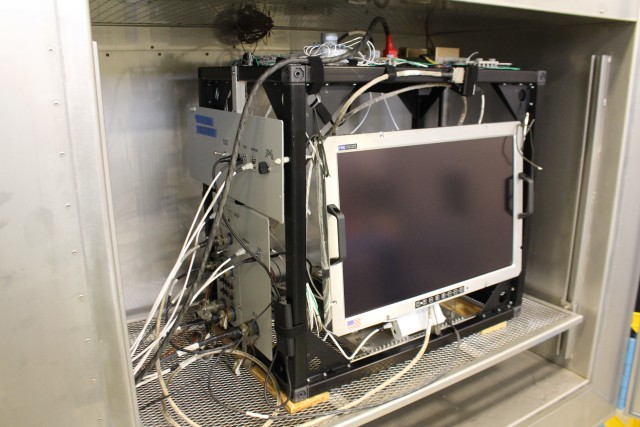

The CASPAN features a twelve-seated palletized conference workspace flanked by large-screen monitors, separated into two sections that can be rolled on and off the planes to provide generals and higher ranked staff with their own airborne mission planning node.

To help determine the CASPAN's component design, CERDEC C4ISR PIF engineers conducted Finite Element Analysis, which is a state-of-the-art virtual analysis method for predicting how products react to physical effects and ran simulations, which included modeling various monitor sizes that would provide the largest viewing area yet also meet the Air Force's strict ready-to-fly standards.

"We test many of our designs for a variety of environmental issues, such as vibration, temperature, humidity, altitude, and shock, which allows us to identify and rectify deficiencies before we deliver to our customers for their own tests," said James Shannon, quality assurance and test team lead for the CERDEC C4ISR PIF.

Engineers subjected the monitors and other components to in-flight conditions at the CERDEC C4ISR PIF Environmental Test Facility and other contractor locations to ensure they remained secure when subjected to G-forces up to and beyond ones experienced during a C-17's takeoff and landing.

"We instituted a pull test on the monitors to ensure they did not deflect more than 13 inches while experiencing 9Gs, or a 1300 pound force, both forward and backward," said Christopher Dubay, CERDEC engineer. "Anything more than 13 inches during a sudden force could result in injury to anyone near the monitors."

After discovering that the monitors moved beyond the 13-inch criteria, CERDEC C4ISR PIF engineers designed a modified monitor mount in two and a half weeks. During the second test, the mounts exceeded the test criteria.

"You design something, you test it, and if fails, you strengthen it," Dubay said. "Our job is to identify and rectify issues before our customers conduct their own tests."

The GRF will also receive CERDEC's Display Viewer Application, or DVA, which is software that captures and shares images from any laptop connected to CASPAN's network and displays that image on the monitors.

"The DVA replaces the video switch boxes normally required for monitors, and whether installed on planes or in the command post, it eliminates 152 pounds of weight, 9.5 cubic feet of equipment and is expected to provide about $70 million cost avoidance for replacement and sustainment costs," said Adam Richwine, CERDEC engineer.

PdM NetMod requested one additional feature to the CASPAN before delivery, which was to split the power source between the two pallets should they wish to fly with six versus 12 seats. C4ISR PIF engineers rapidly completed and tested this requirement to meet the customer's tight schedule, Richwine said.

"Having the CERDEC C4ISR PIF team co-located with our team expedites any changes we may need to make to best support our customers," Henderson said. "This partnership continues to produce capabilities that are enhancing the Army's Mission Command capabilities."

PdM NetMod recently delivered the CASPAN to the 50th Expeditionary Signal Battalion, 35th Signal Brigade, which supports the XVIII GRF. The CASPAN promptly received the U.S. Air Force's "Safe to Fly" designation, and the unit plans to field it sometime this fall.

"We face challenges as we develop prototypes for the Soldiers, but it's our job to overcome these challenges and at the same time deliver our products within schedule," said Shannon. "When you assume some risk you trust your engineers' instincts, and therefore you are more likely to create and deliver the next great product to the warfighters."

Social Sharing