Corpus Christi Army Depot's Cleaning Shop is running much more smoothly this summer thanks to a small team of shop floor professionals focused on process improvement.

This talented team of experts developed three solutions to improve backflush operations to keep the T700 Engines program on schedule for its customers.

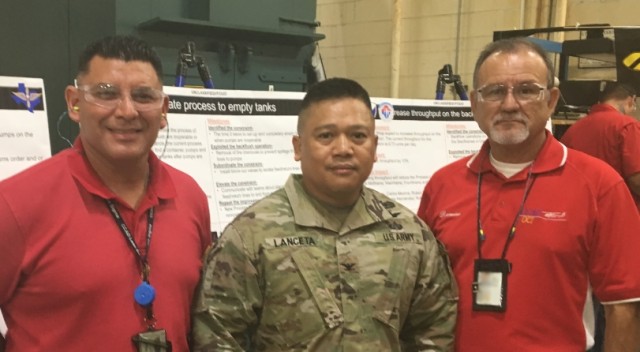

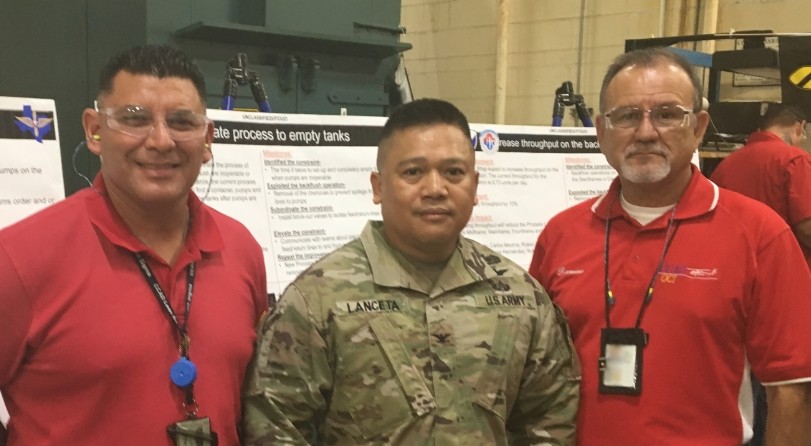

Subject matter experts Ruben Rodriguez, Robert Vargas and Rene Hernandez collaborated to improve the current process while Carlos Medina documented the project.

VISUAL INSPECTIONS

The team identified several opportunities to increase the workflow at a reduced cost on the front, mid, swirl, and main frames.

They noticed that visual inspections constrained their backflow process consistently.

A look at the data on the last thousand visual inspections revealed there were zero failures identified. Technical data also revealed that there was no requirement for visual inspections on the backflush operations.

Quality Control teams agreed to remove visual inspections from the backflush standard operating procedure, which reduced cost by 27% and increased daily production by 55%.

REPLACING PUMPS

The maintenance team, which included CCADers Homer Silva, Eddie Vasquez and Carlos Garza, hit another constraint each time backflush operations encountered a pump failure. The current process required a week of equipment down time as crews ordered and awaited the delivery of new pumps to replace the failed ones.

The team recommended a simple fix: By keeping spare pumps on hand, the average down time for pump failures decreased from seven days to only three to four hours.

CHEMICAL FLUSH

Before removing pumps, backflush equipment have to be cleared of all chemicals. This prevents spillage.

This chemical flush process consists of halting operations, ordering and awaiting delivery of a special container, and pumping out and storing all chemicals. To complicate matters further, these in-direct labor processes would be performed by direct labor personnel.

But 2nd shift work leader, Eddie Guerrero had an idea. He recommended incorporating shutoff valves to isolate the feed and return the lines to the pumps, thus eliminating the process to empty the tanks to include storing chemicals and refilling tanks.

CCAD's new process would now include valve shut-off, pump removal, pump replacement with spares and open valves for use. These improvements ensure that CCAD can have a smoother production flow on the backflush operations.

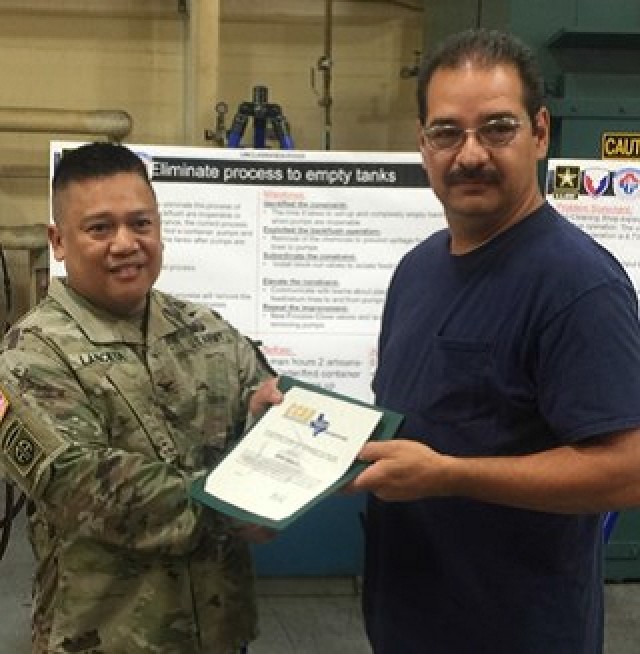

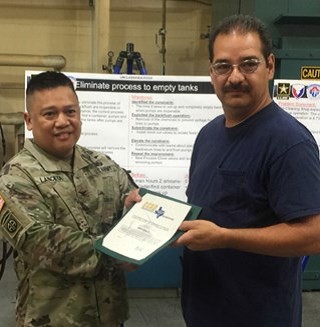

Depot Commander Col. Allan H. Lanceta recognized the Cleaning Shop personnel for their extraordinary improvement efforts, 1 July 2017.

Social Sharing