WATERVLIET ARSENAL, N.Y. (June 2017) -- The Army's last remaining cannon manufacture has a great history of rising and then falling in stature after every military conflict since the War of 1812. But interestingly, it was not the wars at home or those overseas that have safeguarded the Watervliet Arsenal's 203 years of continuous operation -- it was a revolution.

When people think about revolutions, they might visualize images of the fighting in the American or the French Revolutions in the late 1700s. But after the American Civil War, there was another type of revolution. And unlike the death and destruction of a typical revolution, this revolution actually saved lives and improved the quality of life of every American.

A few years after the American Civil War, America entered into what was then called the Great Depression, only to be followed by another Great Depression in the 1930s.

As with any depression, there were significant worldwide economic challenges and extreme shortages of basic goods, except for one area -- there were no shortages of tinkerers, designers, and discovers who led what would become known as the Second Industrial Revolution.

During this revolution, which many say ran from the 1870s to the start of World War I, significant scientific discoveries that would effect the lives of everyday Americans were brought out of dusty research labs and into businesses and homes. One such discovery, generating power from magnetic grids, allowed manufacturing centers to move toward mass production by powering machine tools with a phenomenon called electricity. With electricity, manufacturers could move away from machines powered by animals, water, and steam. During this same time, a new invention called the incandescent light bulb would provide consistent, safe lighting to manufacturing production floors and offices.

The Revolution also drove growth in the field of metallurgy, which greatly benefited the Arsenal, too.

G. Peter O'hara, a retired Army mechanical engineer from the Arsenal, said that advancements in metallurgy in the 1870s allowed for the mass production of a hardened allow called steel.

Steel had an immediate effect on the quality of life of every American as it allowed for a massive expansion of railway systems by replacing iron rails, which were easily damaged and could not withstand the weight of larger locomotives, with cheaper, stronger steel. This technology allowed for the rapid migration of people and products throughout the country and is still in use today.

O'Hara added the Revolution's advancement in metallurgy also drove significant advancements in weapons technology.

"As nations began to mechanize their defense industrial base after the American Civil War, advancements in weapons technology was just a logical expansion of the science of the time," O'Hara said. "Four key advancements made in large caliber production led to the transformation of the Watervliet Arsenal from a maker of saddles to a maker of cannons."

First, the "ball" projectile was replaced by a more aerodynamic spherical munition. This new round, when combined with an inner-bore technology called "rifling," greatly increased the range and accuracy of artillery and naval-gun systems, O'Hara said. The third new technology involved replacing cast-iron guns with steel guns, which improved the durability and accuracy of the gun tubes. And finally, the introduction of breech loading greatly reduced reloading time, while improving the safety of artillerymen.

By the early 1880s, the United States was becoming a world super power, but it lacked the ability to produce large modern cannon guns for its army and navy. The bottom line is that U.S. weapon systems of that period were overmatched by foreign militaries.

"Oceans had once provided a barrier against foreign armies, albeit not impregnable, for centuries," O'Hara said. "Nevertheless, by the 1880s, foreign militaries had amassed large naval platforms that could deliver devastating fires onto coastal communities from a large standoff distance."

Given that U.S. harbor fortifications were sadly inadequate, President Grover Cleveland appointed a Board on Fortifications or Other Defenses, also known as the Endicott Board, to determine the best locations to manufacture cannon, siege, and seacoast guns.

The president and Congress agreed to fund the startup of two cannon manufacturing centers. One for the Navy at the Washington Navy Yard in Washington, D.C., and one for the Army at Watervliet, N.Y.

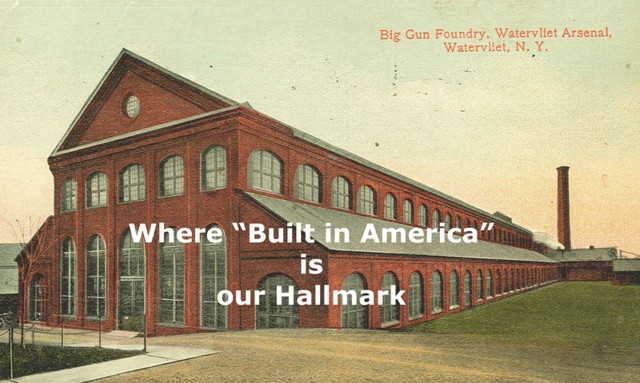

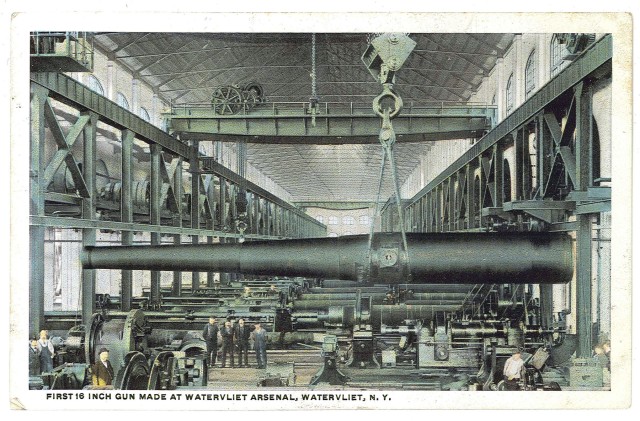

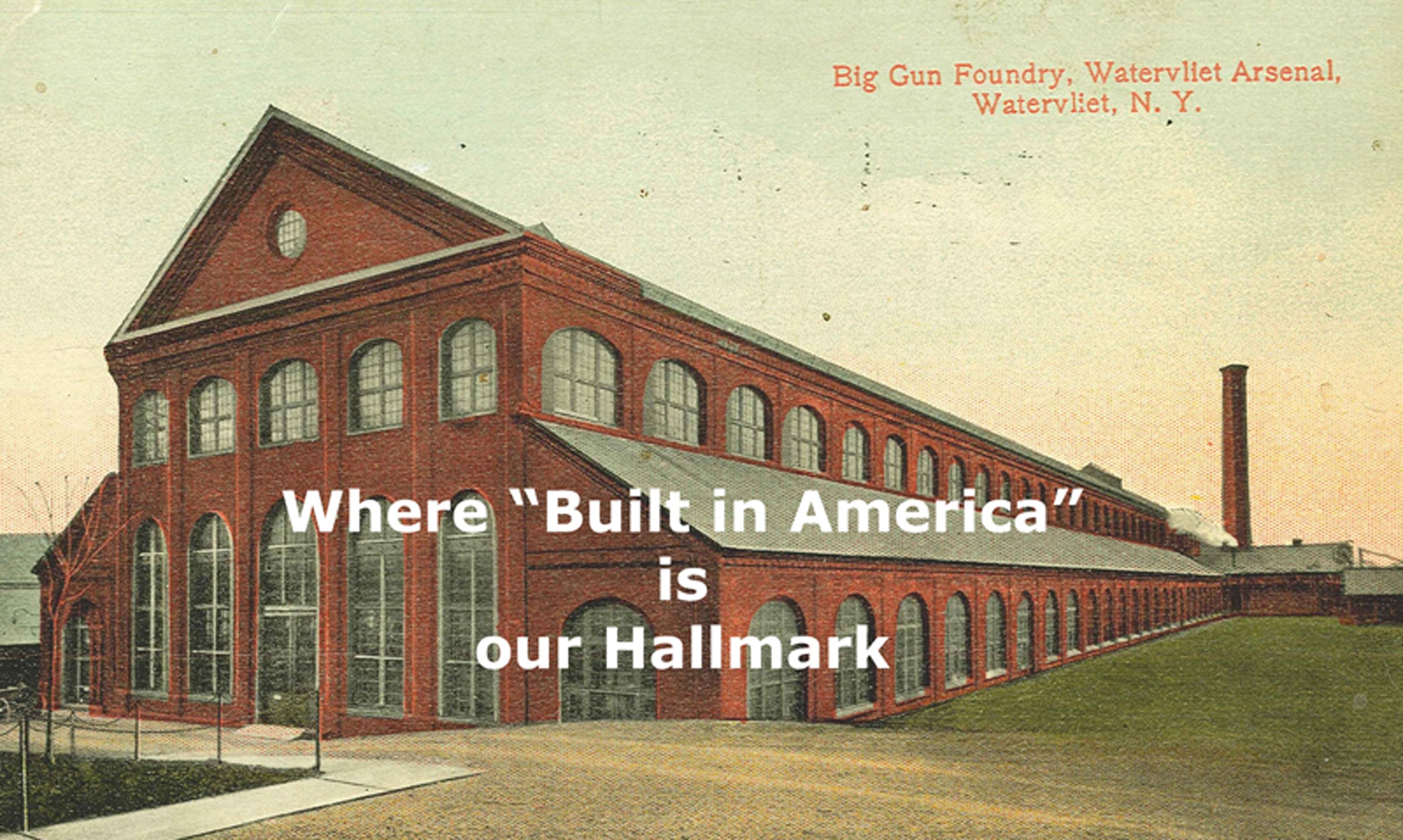

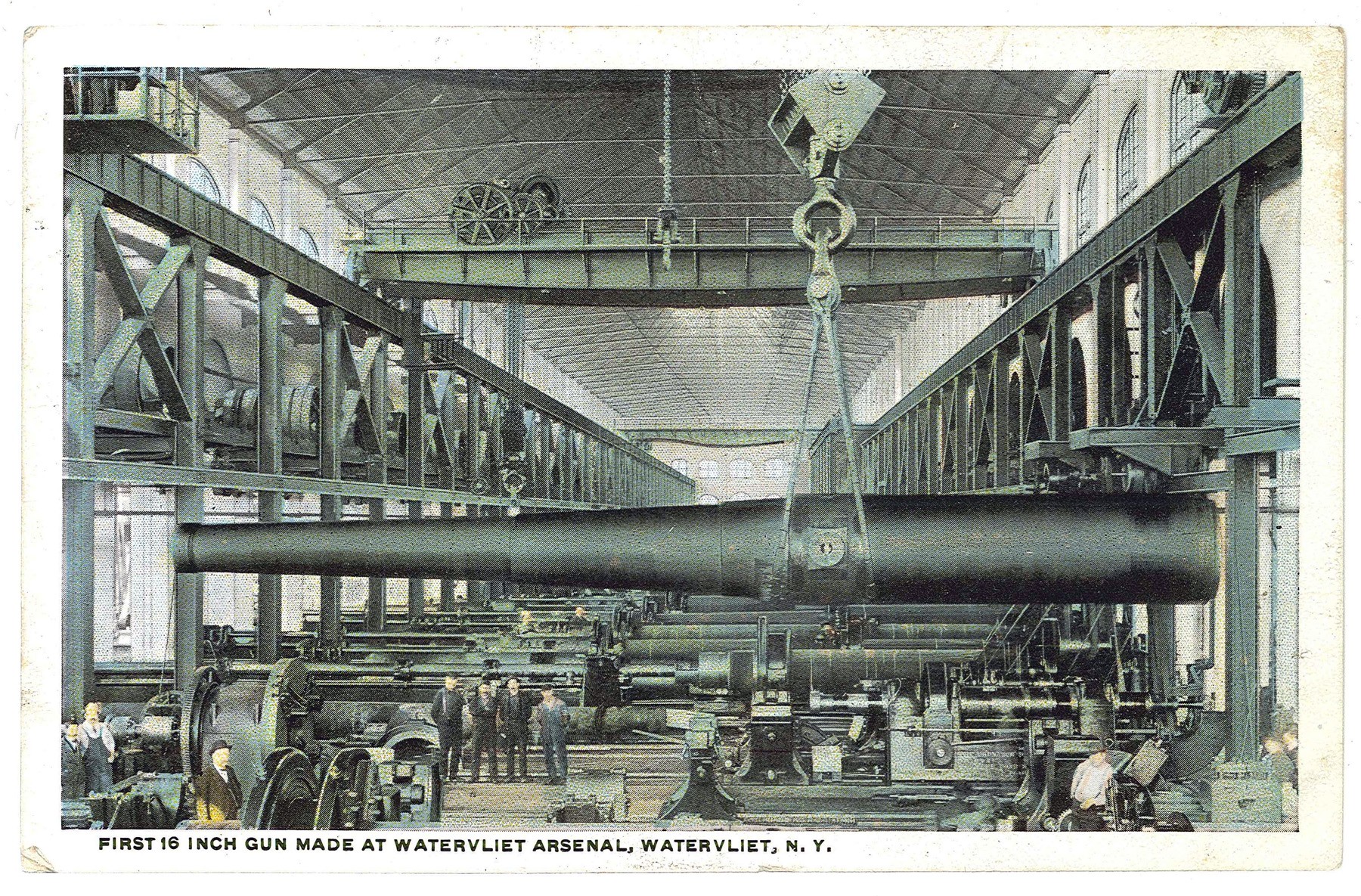

And so, with the relocation of several machines from the Watertown Arsenal and about $700,000 from Congress in 1887, the Arsenal began the transformation from a maker of saddles to a maker of cannons in what has become known here as the "Big Gun Shop."

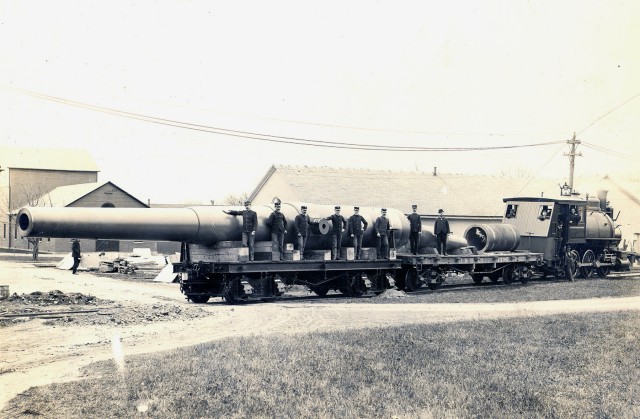

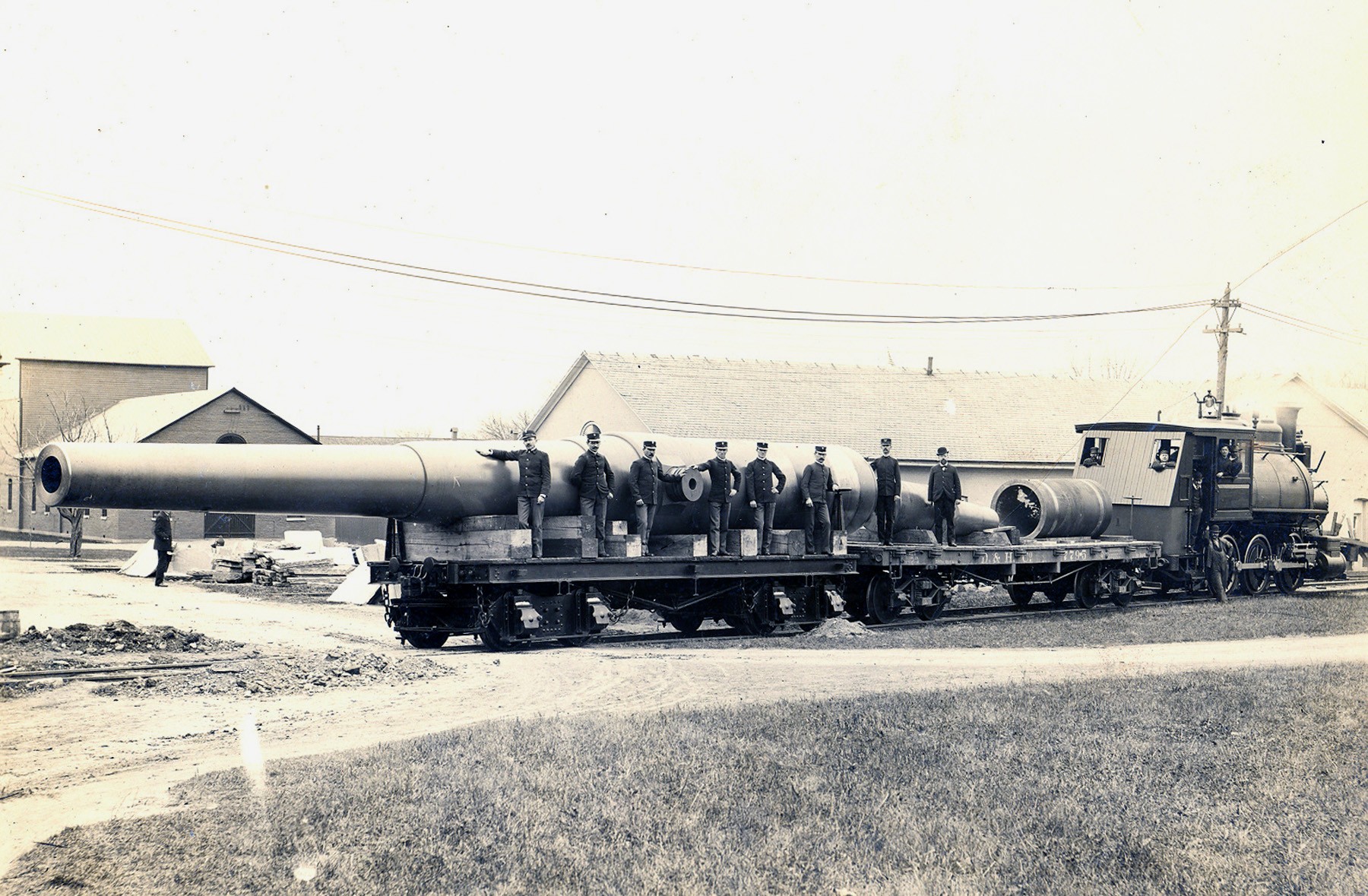

By 1890, the Arsenal had produced its first large caliber gun, an 8-inch cannon. By 1893, the Arsenal was manufacturing 8-, 10-, and 12-inch guns and mortar systems. By 1902, the Arsenal manufactured its first 16-inch cannon.

In the years that followed, the Big Gun Shop grew from the original 166 feet in length to approximately 1,300 feet by World War I. Some of the gun systems manufactured in this building included 8-, 10-, and 12-inch guns; 12-inch breech loaded mortars; 12- and 14-inch coast defense guns; and 16-inch guns for coast defense and for battleships.

______________

The Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest, continuously active arsenal in the United States having begun operations during the War of 1812. It celebrated its 200th anniversary on July 14, 2013. It is a subordinate command to TACOM LCMC and the Army Materiel Command.

Today's Arsenal is relied upon by U.S. and allied armies to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark had revenue in fiscal year 2016 that exceeded $126 million and provides an annual economic benefit to the local community in excess of $90 million.

Related Links:

Watervliet Arsenal Slideshare Page

Watervliet Arsenal YouTube Page

Watervliet Arsenal Twitter Page

Social Sharing