FORT DRUM, N.Y. -- Engineer units have a long history of supporting Fort Drum's infrastructure development and maintenance, and the 642nd Engineer Support Company continues that tradition today.

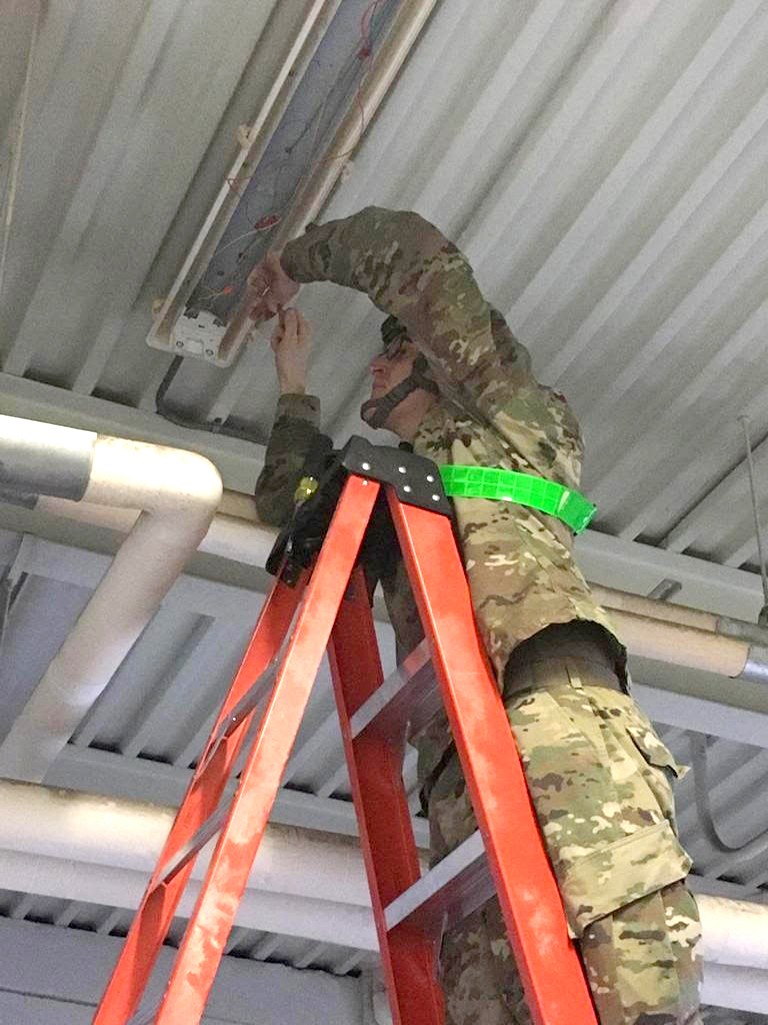

Recently, Soldiers from 3rd Platoon, 642nd ESC, helped with a project with potentially significant energy and cost savings for the installation. Fort Drum Public Works staff identified 29 buildings where the old fluorescent lighting and ballast could be replaced with a new energy-efficient LED system. The interior electricians started the project in their own building on Camp Swift Road and exchanged 752 fixtures using roughly 1,500 bulbs.

First Lt. Edward Mathieson, 642nd ESC Vertical Platoon leader, said that as a tenant unit on post, the engineer Soldiers were more than capable of taking on this assignment while PW staff members focused on work orders with a higher priority.

"They've been looking at trying to update these buildings for a while but it hasn't been possible with all the maintenance and upkeep they have to do," he said. "We were fortunate to be able to step up and assist with this."

The new lighting system is not only energy-efficient, but the upgrade will eliminate the root of future issues, Mathieson said.

"Whenever a light goes out, it becomes an issue of whether it's the bulb or the ballast that stopped working," he said. "With these system upgrades, the Soldiers themselves will be able to fix the problem because it's only going to be bulb issues and not ballast."

Approximately 5,000 replacement tubes are on order, and Mathieson said that because the technology is so new, the manufacturer has yet to produce all of them. If all 29 legacy buildings were converted, the project could save Fort Drum and the Army an estimated $400,000 annually in energy and maintenance costs.

"This first building is basically the test phase, and it took 10 Soldiers about 25 working days starting in late January," he said. "So now we're in the trial period where PW will analyze the impact -- the cost savings, energy efficiency -- based on the estimates made."

Jason Towne, PW journeyman electrician, oversaw the project and made sure the lighting installation was performed correctly and within their timeline.

"Towne instructed the Soldiers on proper safety procedures and light fixture modifications," said Jay Steiner, PW lead engineer technician. "He was instrumental in keeping engineers supplied with materials and observed as they moved throughout the facility, ensuring safety was their priority."

The PW Business Office staff was excited about working with the 642nd ESC, Steiner added, and he was appointed as project manager.

"I'm a veteran of the Air Force and worked in a shop with both military and Civilians," he said. "I know the importance of years of experience that the civilian workforce has, and it can be extremely rewarding."

Steiner said that the new lighting system has an operational life of about 10 years, depending on hours of usage. An average fluorescent bulb can last about 25,000 to 30,000 hours, while LED lights average between 60,000 and 80,000 hours and use half the power in comparison. LED tubes also are non-hazardous and completely recyclable.

"This was a win-win for Fort Drum and the 642nd," Steiner said. "Fort Drum is saving dollars by having high-efficiency LED lighting installed at little or no contract or workforce costs, and the energy savings are huge. The 642nd gained valuable experience working with Jason and myself. They were exposed to the working components of the fluorescent fixtures and gained experience in on-the-job training."

Other projects

Besides the lighting project, Soldiers from 1st Platoon partnered with PW's snow removal crew during winter months to clear more than 12 square acres of motor pools and parking lots, to include McEwen Library, Central Issue Facility, Logistics Readiness Center and the Supply Support Activity.

According to 1st Lt. Greg Sacenti, platoon leader, Soldiers used two motor graders and a five-yard scoop loader for snow and ice removal operations and accumulated 349 hours of work that saved the installation nearly $37,000 in contracting costs.

In addition, Soldiers from 2nd Platoon, 642nd ESC, completed a four-month project in February that involved cutting down 30 acres of trees to provide clear entrances to the airstrip used by unmanned aerial vehicles at Wheeler-Sack Army Airfield. Second Lt. Robert Skinker, platoon leader, said that the trees would cast shadows on the airstrip, and operators were dealing with wildlife in the area.

"This project was on the garrison's priority list to prevent any damage to these very expensive UAVs and make this a safer and more reliable airstrip," he said.

Skinker said that he had not yet assumed command of the platoon during the project, but he was told it was all done by chainsaws.

"It would have been much easier with bulldozers, but this project was assigned to them before that equipment had gotten here," he said. "It had to get done, and the Soldiers cleared the trees with chainsaws."

Skinker said that the Soldiers have returned to the airfield for additional work since the project wrapped up.

"We've gone back and probably cut down another five acres, and I would say this is now basically maintenance," he said. "It's down to a safe and usable level, but every once in a while pilots will still have concerns about some of the areas. Now that we've set up this relationship with the garrison and the airfield, I imagine we'll continue to take care of any issues with that."

Mathieson said that the 642nd ESC officially stood up in October, under the 46th Engineer Battalion at Fort Polk, La., but the unit is associated with the 91st Military Police Battalion at Fort Drum. The company was previously attached to the 7th Engineer Battalion in 2014.

He said they are excited to take on these types of projects that strengthen their readiness and support Fort Drum's infrastructure development and maintenance. Currently, the engineer Soldiers are assisting in construction and maintenance projects on training ranges.

"From the very beginning, we've been trying to establish a good working relationship with Fort Drum Public Works," he said. "We're still trying to make a name for ourselves here, and so we're always looking for ways to support and assist in daily operations and modernizing Fort Drum."

"These kinds of projects are great for engineers because it gives us this cyclic training, and the more that we have, then the more Soldiers we can rotate back into those projects," Skinker said. "We can go out to our training areas and dig and conduct our regular training, and that's no problem. But if we can make our training help the community, then it has a bigger impact for everyone."

Social Sharing