The Combined Arms Support Command's Army 2020 and Beyond Sustainment White Paper (2013) asked what the future Army, as part of the joint and multinational force, must do to integrate and synchronize operational and institutional sustainment forces and capabilities to effectively sustain unified land operations. Revitalizing materiel management capabilities at both the corps and division levels is a critical component to ensuring readiness for the next fight.

The 4th Infantry Division (ID) and Fort Carson, Colorado, leaders have identified the need for a division materiel readiness center (DMRC). Establishing a DMRC that is focused on managing information and visibility and on creating a shared understanding is critical to developing a single logistics common operational picture, reducing redundancy, gaining sustainment synergy, and ensuring readiness. The primary goal of a DMRC is to make readiness preeminent, which will ensure the operational endurance of division elements.

UNDERSTANDING THE PAST

According to the commander of the Training and Doctrine Command, from the late 1970s until the early 1990s the military defined its focus as "how to fight the Soviet Union in the central plains of Europe with NATO, outnumbered, and win."

To change the battlefield calculus, the Army invested in five key technologies (the M1 Abrams main battle tank, the M2 Bradley fighting vehicle, the multiple launch rocket system, and Apache and Black Hawk helicopters) and developed the industrial enterprise to sustain forward-basing requirements at the height of the Cold War. Leaders knew that the best way to deter a potential adversary was to build a military capable of power projecting a force that could amass fires against multiple threats simultaneously and sustain long campaigns to defeat the enemy.

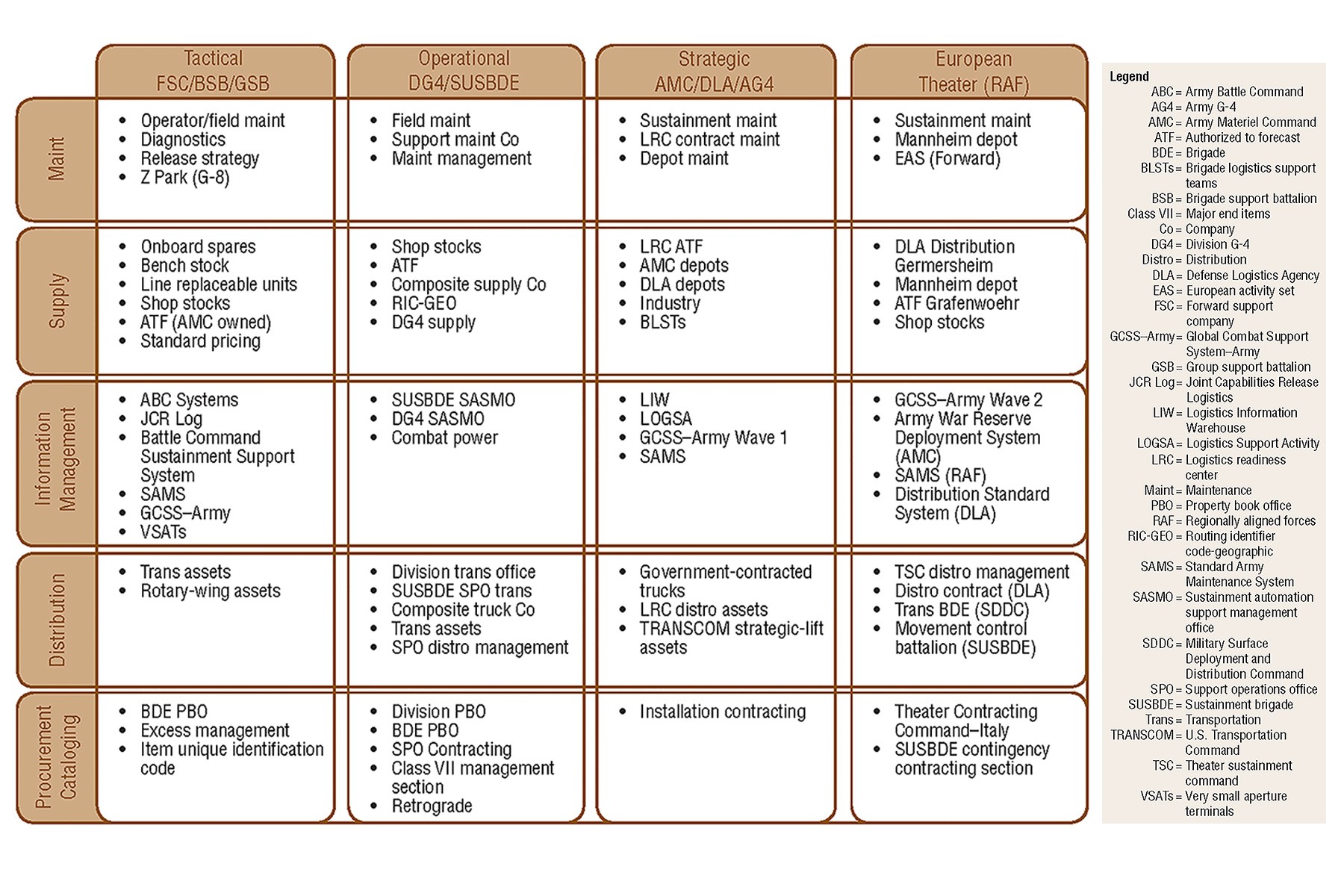

Theater, corps, and division materiel management centers (DMMCs) were essential to maintaining centralized control of materiel to ensure readiness. The DMMC provided the division commander with centralized and integrated materiel management for classes I (subsistence), II (clothing and individual equipment), III (petroleum, oils, and lubricants), IV (construction and barrier materials), V (ammunition), VII (major end items), and IX (repair parts) and maintenance. Some of the key functions of the DMMC included the following:

• Supervision of the division's authorized stockage lists.

• Management of the division master property records.

• Management of the maintenance workloads of corps maintenance assets in support of the division.

• Management of the division class IX system.

• Management of weapon system replacement operations.

During a linear fight with multiple echelons of sustainment, it was necessary to have a degree of controlled management because of the long lines of communication that characterized the supply chains. Centralized management was essential because logistics automation systems were still immature. An example of a textbook linear campaign that necessitated centralized materiel management was the Persian Gulf War.

POST 9/11

After 9/11, the military found itself engaged in another conflict in the Middle East. The environment had changed, requiring modular rotational forces to deploy periodically in support of simultaneous asymmetric campaigns in both Afghanistan and Iraq.

The Army managed the rotation of forces using the Army Force Generation (ARFORGEN) model. ARFORGEN allowed a unit to build readiness just in time for its major validation exercise prior to deployment. But after returning from deployment, the unit would not sufficiently maintain its readiness.

During this period, the Army looked for ways to increase it responsiveness and deploy capabilities at a sustainable rate to meet the requirements of battlefield commanders. The Army decentralized much of its materiel management capabilities by placing them in brigade combat teams (BCTs) and relying on contracted support for other functions that were part of the pre-9/11 force.

Because of the enemy's constant adaptation, the military was required to rapidly adjust its tactics, equipment, and sustainment. The national industrial base focused its efforts on quickly producing new systems, such as the mine-resistant ambush-protected vehicle, the Stryker family of vehicles, and other combat systems, many of which were maintained by contractors.

Contractor-provided maintenance came at a cost. For example, some legacy fleets, including tanks and Bradleys, were not well maintained. In the end, this maintenance model was not sustainable, expeditionary, or affordable.

THE DMRC CONCEPT

Realigning sustainment brigades back with divisions provided an opportunity to rebuild an architecture similar to the DMMC but much more information-based and readiness-focused.

The DMRC concept is designed to ensure sustainment efforts are integrated with joint force requirements to guarantee unimpeded sustainment in a crisis across all domains without any force structure growth. It also provides BCTs with greater enabling sustainment capacity without taking away any of their organic capabilities.

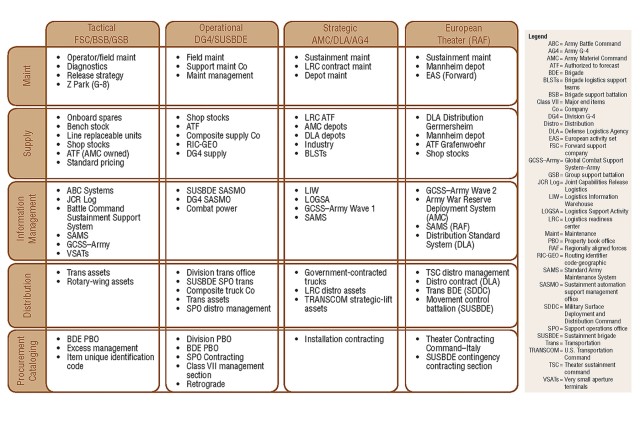

To achieve these ends, the Fort Carson sustainment team analyzed successful business models that applied vertical and horizontal integration to increase effectiveness. (See figure 1.) The team explored vertical integration options to reduce stovepipes, integrate systems and processes, and increase information sharing. The team studied horizontal integration concepts in order to increase trust, influence, and collaboration and leverage capabilities.

The team explored options to flatten sustainment processes in order to speed tactical outputs (procurement, distribution, supply, maintenance, logistics, and information systems) and analyzed the integration of these functions by sustainment echelons above the battalion level.

The Fort Carson sustainment team found that integrating functions greatly reduced stovepipes of information, which increased speed, accuracy, shared awareness, and the ability to anticipate problems. These reductions, in turn, increased readiness across the division.

Before implementing the DMRC concept, the division had at least four different sustainment organizations reviewing equipment status reports and researching parts; all reported a different readiness picture.

Using the DMRC concept flattens communications, increases collaboration, builds trust through influence, and helps to resolve problems before they become readiness issues. The concept integrates key readiness functions, such as combat-power tracking, logistics common operational picture generation, reporting, maintenance, standard Army management information systems, class VII, financial management, and combat spares and supply ordering, receipt, and distribution.

The DMRC integrated liaison officers from each BCT with fleet management teams to influence the direction and focus of the BCTs on critical sustainment issues. The fleet management teams, BCT liaison officers, and commodity managers conducted a monthly review and analysis of the entire logistics enterprise to holistically anticipate and resolve issues and leverage internal and external agencies that can affect readiness.

The DMRC Research and Analysis Cell conducted anticipatory analysis based on the commanding general's priorities. For example, it conducted a detailed analysis of the last four armored BCT rotations at the National Training Center at Fort Irwin, California, to determine the high-demand parts that should be added to logistics push packages or "authorized to forecast" lists prior to rotations. The staff also analyzed recurring faults with long lead times to prime the national industrial base for the next rotation.

In coordination with the 21st Theater Sustainment Command, the Research and Analysis Cell also conducted analysis to assist with the upcoming deployment of the 3rd Armored BCT to support the Operation Atlantic Resolve regionally aligned forces mission. While the BCTs focused on immediate readiness, the DMRC team focused on deep readiness (readiness more than 20 days away) and eliminating systematic problems that adversely affected readiness across the division. For example, the DMRC team conducted in-depth analysis of Fort Carson supply support activities and combat spares to ensure the division was stocking the right number of critical parts in time to ensure readiness of the 4th ID BCTs.

ENABLING THE FUTURE FIGHT

In future conflicts, the DMRC would primarily generate readiness from a home-station mission command center or a division sustainment operations center. The DMRC would also have the ability to deploy forward as part of the sustainment brigade headquarters or as a smaller fleet management team focused on generating readiness for a particular BCT.

Under this concept, the forward deployed sustainment mission command element, with mission-tailored commodity management capabilities, would reach back to the DMRC through secure tactical communications. This reach-back capability reduces the requirement to forward-station large sustainment formations to solve problems. This concept is currently being employed as part of the deployment of the 3rd Brigade, 4th Infantry Division, in support of Operation Atlantic Resolve.

The DMRC provides the forward mission command element with near-real-time problem-solving and access to data. Macrodata is uploaded both from forward and rear locations into an encrypted web-based portal that pulls microdata from a cloud-based system. This decreases the reliance on email and meetings as the primary sources of information. (Aggregating microdata from emails and meetings inherently creates delays.)

Increased reporting accuracy, data sharing, and a shared understanding will greatly enhance the ability of the joint force to generate readiness, project power, anticipate requirements, sustain readiness, and ensure operational endurance. Revitalizing materiel management capabilities at both the corps and division levels is a critical component to generating and ensuring sustained readiness for the next fight.

--------------------

Col. Ronald R. Ragin is the commander of the 4th ID Sustainment Brigade at Fort Carson, Colorado. He holds a bachelor's degree from the University of Texas, a master's degree in strategic studies from the Naval War College, a master's degree in international relations from Troy University, and a doctorate in public policy from Walden University. He recently completed the Harvard National Security Fellowship, and he is a graduate of the Harvard John F. Kennedy School of Government in Cambridge, Massachusetts.

Lt. Col. James M. Callis, 4th ID G-4; Lt. Col. Jason McKay, 4th ID Division materiel readiness chief; Lt. Col. Mark. W. Vandersteen, commander of the Army Field Support Battalion-Fort Carson; Maj. Curtis L. Yankie, the 4th ID Sustainment Brigade support operations officer; and Maj. Christopher M. Richardson, 4th ID Sustainment Brigade's executive officer, contributed to this article.

--------------------

This article was published in the May-June 2017 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing