"The Sustainability team clearly demonstrates how fully engaged leadership, coupled with sound environmental practices and innovative approaches, can directly enhance Army readiness," said Mr. Eugene Collins, Deputy Assistant Secretary of the Army for Environment, Safety and Occupational Health.

The team was especially successful this award year with waste stream reduction and diversion. Their efforts established recycling, reuse and resale of solid waste and other materials, resulting in more than 50 percent reductions in universal waste streams compared with the 2012 baseline, as well as 44 percent reduction in hazardous waste.

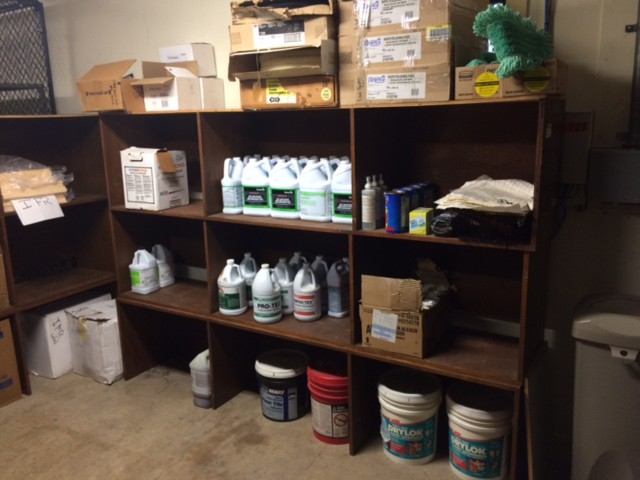

Formalizing a pharmacy exchange program for materials throughout PAARNG's properties was a huge team undertaking. Previously, units turned in items they did not need to the Sustainability program. Now, the team documents inventory--everything from cleaning supplies to drywall screws--and updates facility managers monthly about new products. In less than one year, the pharmacy avoided over $15,500 in disposal costs and avoided $30,000 in redundant purchases. This is one of several initiatives other military installations and agencies could adopt.

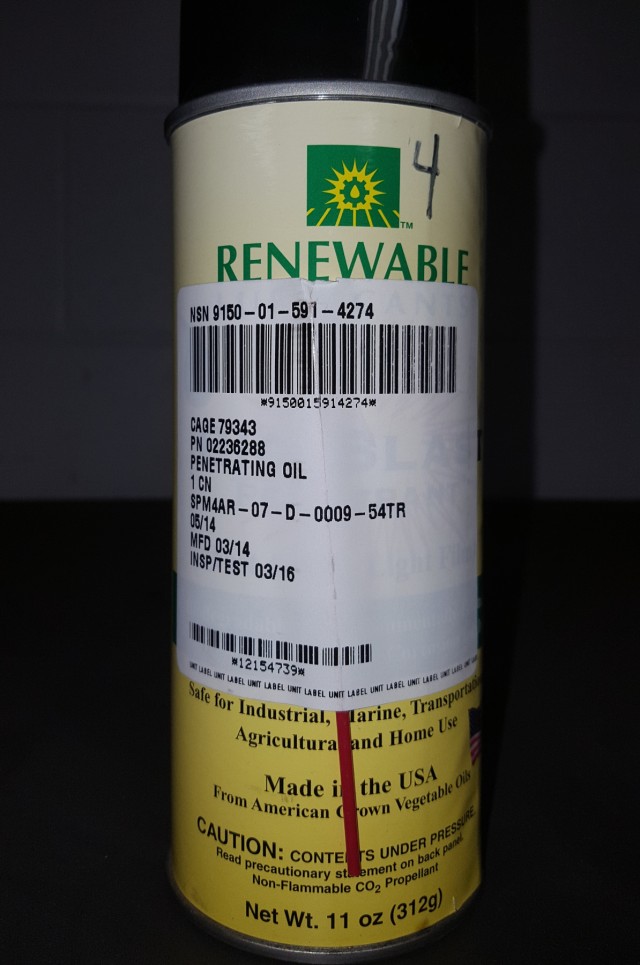

In the past two years, the team worked with local Defense Logistics Agency to divert materials that would otherwise be disposed of conventionally or as hazardous waste; they also work with the U.S. Property and Fiscal Officer and local recyclers to recycle materials. Mixed brass, telephone poles, batteries empty gas cylinders and empty aboveground heating oil tanks are just a few examples of materials processed. Their efforts and associated savings were substantial.

"Although it is challenging to divert waste streams for recycling and reuse, at the same time it is rewarding when you step back and look at the success as a whole," said Megon Riddell, PAARNG Environmental Specialist.

Another team effort is recovering lead from rubber blocks on FTIG-NGTC's ranges. Working with a contractor, PAARNG's cost is 70 percent less than disposing of the blocks as hazardous waste. Concrete from demolition projects is also recovered and reused, and PAARNG's forestry department uses excess fuels when possible in the prescribed fire program, avoiding costs for hazardous waste disposal and buying fuel.

At FTIG-NGTC's largest maintenance shop, the team implemented a water jet system that reduces hazardous waste to a minimum, and the team helped unit coordinators and shop managers substitute potentially harmful materials with safe green alternatives. For example, a citrus-based degreaser product replaces chlorinated products such as carburetor cleaners, mineral spirits and petroleum naphtha.

At the wastewater treatment plant, a sludge press captures bio solids that fertilize hay on 25 acres; harvested hay is used for projects like sedimentation control. In the first eight months of 2016, the press helped avoid disposal costs of almost $20,000. Converting FTIG-NGTC to natural gas heating and LED systems continues. New construction incorporates efficient features, and retrofits are ongoing around the state.

Dreama O'Neal, Environmental Compliance Manager, acknowledges the following sustainability team members: Megon Riddell, Environmental Specialist; Todd Eakin, Environmental Supervisor; CW3 Michael O'Donnell, Field Maintenance Shop #4 Shop Supervisor; CW3 Chris Prinzivalli and Field Maintenance Shop #4 Shop Foreman.

"But also beyond those specifically identified above, the waste stream diversion, the pharmacy reuse program and the hazardous material substitutions encompass a much larger team of people within the PAARNG staff," O'Neal said.

Social Sharing