FORT RUCKER, Ala. (March 13, 2017) - Have you ever asked yourself how an accident could have been prevented? An overview of the tools investigators use to evaluate an accident can help leaders in pinpointing trouble areas ahead of time. Identifying these trouble areas may assist proactive leaders with preventing the next mishap.

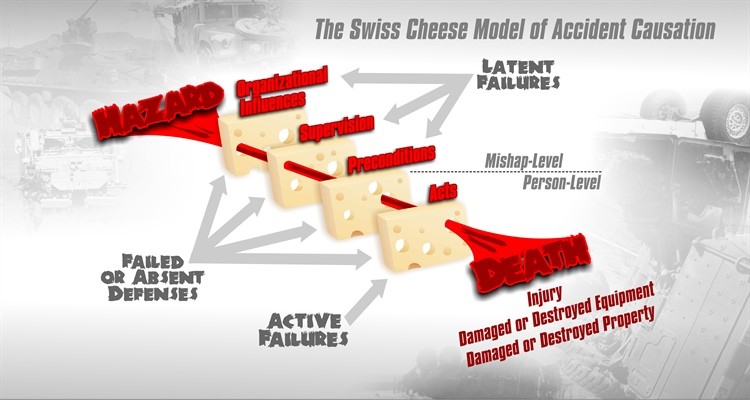

One of the tools investigators use to conduct accident/mishap investigations is the HFACS 7.0 (Human Factors Analysis and Classification System). The HFACS was developed by behavioral scientists to evaluate how performance and human factors contribute to mishaps. Within the HFACS is the Swiss cheese model, which helps illustrate how a mishap occurs through several layers of failures or errors. The HFACS helps investigators get to the "why" of the mishap, not just the "what." As you glance at this model, please take a second to think about an accident that happened in your motor pool or with a vehicle.

Acts:

Most of us remember an act that led to a Soldier's injury. The act or active failure component starts at the lowest level and involves the Soldier's decision that led to the mishap. An active failure typically involves something the Soldier did or did not do. This includes failure to follow procedures, making a wrong decision or violating a regulation. Understanding this stage of the HFACS model can assist leaders with focused training to mitigate these risks.

Preconditions:

The preconditions of a mishap often come from environmental factors, physical or mental stress, and personal issues. These can include a variety of factors, including fog, dust, weather, restraint systems, instruments, workspace, communication equipment, mental awareness, state of mind, effects of substances, loss of consciousness, fatigue, nutrition, body size or physical strength. Recognizing these preconditions ahead of time may make the difference in preventing a mishap in your workplace.

Supervision:

The third slice of cheese in the model illustrates the command's role in the mishap. This typically involves a supervisor's knowledge of the preconditions, failing to enforce standards, allowing Soldiers to violate existing regulations, permitting untrained Soldiers to operate equipment or conduct a task, exceeding capabilities, failing to provide adequate oversight or failing to provide training opportunities for Soldiers. Focusing on effective training and enforcing standards is the greatest area leaders can impact safety and prevent mishaps. This also includes the use of Deliberate Risk Management to identify hazards, develop controls and make risk decisions.

Organizational influences:

The final slice of the Swiss cheese model looks at the organization as a whole and reveals gaps that are created through lack of resources, funding, personnel, infrastructure, using aged equipment, excessive OPTEMPO, inadequate training, lack of procedural guidance, unclear mission or inadequate organizational structure. Understanding where organizational shortfalls exist enables leaders to address these issues with the command. These shortfalls may merit elevating the decision authority for missions or tasks that carry higher levels of residual risk.

Conclusion:

The Swiss cheese model reveals that a mishap rarely has just one failure or act. There are layers of failures or "absent defenses" from the organization down to the individual Soldier that line up and allow a mishap to occur. A Soldier that was injured while using a winch on a wrecker may have made a poor decision to violate procedures in the technical manual. However, the HFACS model reveals this mishap may also be contributed to fatigue, lack of leadership oversight, inadequate standard operating procedures or even high OPTEMPO. Risk mitigation requires thinking about the big picture and taking necessary steps to safeguard our Soldiers.

The methodology of the HFACS not only helps accident investigators get to the root causes of a mishap, it allows leaders to assess their organizations to prevent conditions that cause accidents. Leaders should be keen to these contributing factors and do everything possible to create a safety culture in their organizations. If you spot Soldiers using shortcuts or taking unnecessary risks while performing a task, ask yourself, "How can I identify preconditions, improve supervision and influence the organization to ensure my Soldiers are conducting their day-to-day jobs in the safest possible manner?"

Knowledge magazine is always looking for contributing authors to provide ground, aviation, driving and off-duty safety articles. Don't let the fact that you've never written an article for publication scare you. Our editors promise to make you look good. By sharing your knowledge, you can make a valuable contribution to those who need your information to do their jobs safely. Your article might just save another Soldier's life. To learn more, visit https://safety.army.mil/MEDIA/Knowledge/TellYourStory.aspx.

Social Sharing