More than a dozen years of combat have offered many lessons learned for Army medicine. As a medical materiel life cycle manager, the U.S. Army Medical Materiel Agency (USAMMA) has learned that every equipping decision has to be both affordable--including life cycle logistics costs--and cost-effective in addressing the known capability gaps. Over-procurement of medical materiel to close a specific gap may reduce our ability to close other gaps and support today's expeditionary Army.

One way we achieve greater and sustainable medical readiness is through centralized management of high-value, high-volume materiel. An example of this centralized management is the Medical Materiel Readiness Program (MMRP), which began in 2007 under the authority of the Office of the Surgeon General.

MMRP consists of four complete 248-bed combat support hospitals (CSHs) that comprise complex equipment that requires annual maintenance on a rotational basis and must be continually updated by the USAMMA personnel at Sierra Army Depot in Herlong, California. USAMMA biomedical maintenance engineers perform technical inspections and calibration on biomedical maintenance-significant equipment for one CSH per quarter. USAMMA funds Sierra Army Depot to perform care of supplies in storage and repairs on the nonmedical associated support items of equipment. The ability to request specific elements or an entire CSH allows the four MMRP CSHs to offset the requirement for the U.S. Army Reserve Command to maintain sixteen 248-bed CSHs and supports the U.S. Army Forces Command's seven 164-bed companies.

UNPRECEDENTED LIFESAVING

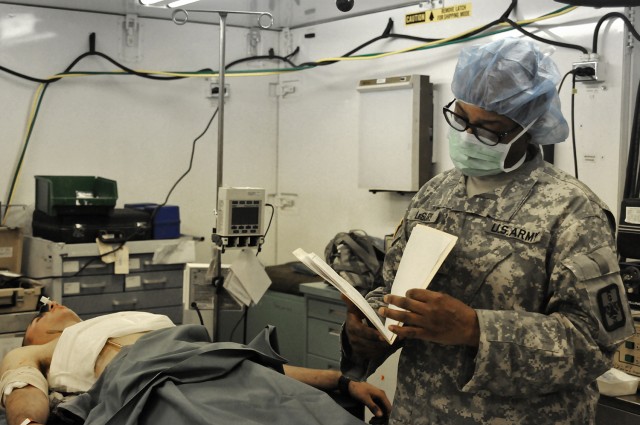

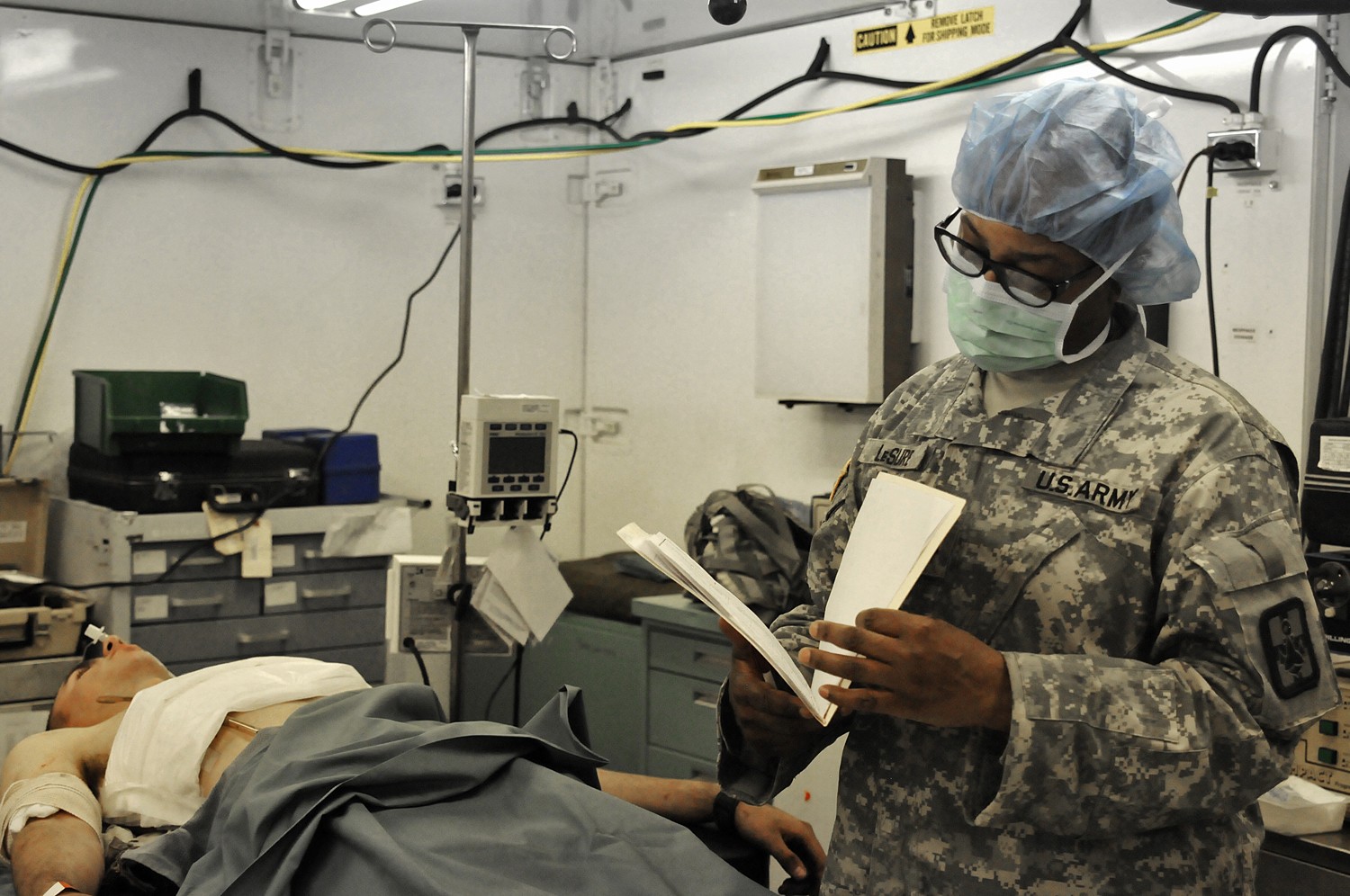

To fully understand the MMRP, you must first envision a CSH, which is the Army's most complex medical unit. Each CSH contains thousands of medical equipment items that are packaged and transported in hundreds of military-owned cargo containers.

CSHs have provided unmatched Role 3 combat health support with a 98 percent survivability rate--the highest in the history of American warfare. The CSH provides hospitalization and outpatient services for all categories of patients within theater. The hospital has four wards providing intensive nursing care for up to 48 patients and 10 wards providing intermediate nursing care for up to 200 patients. The CSH offers pharmacy, psychiatry, public health nursing, physical therapy, clinical laboratory, blood banking, radiology, nutrition care services, emergency treatment receiving, triage, and preparing incoming patients for surgery. Within the hospital, there are surgical capabilities that include general, orthopedic, thoracic, urological, gynecological, and oral and maxillofacial--based on six operating room tables staffed for 96 operating table hours per day. Consultation services for inpatients and outpatients include area support for units without organic medical services.

Role 3 capabilities includes resuscitation, initial wound surgery, postoperative care, and more advanced ancillary services. To maintain their success rate, CSHs need significant maintenance support, as well as regular modernization to keep them updated and fully operational. Additionally, many pieces of lifesaving medical equipment, such as computed tomography (CT) scanners, are expensive and technically sophisticated, requiring specialized equipment care and calibrations performed by certified maintainers. By centrally managing four CSHs through the MMRP, USAMMA is able to ensure medical materiel that requires a significant level of regular maintenance is fully operational at all times and capable of being deployed to support active and reserve units based on the needs of the mission.

Though the MMRP was first developed as part of the Army Medical Department investment strategy to support the Army force-generation model, the program now supports the sustained readiness model, underscoring the need for all Army units to be ready to deploy at all times. As mission demands grow and resources shrink, it is imperative that these four CSHs are sustained at the highest state of readiness. Anything less is not an option.

Since its development, MMRP has been called on by the Army several times. In 2009, USAMMA deployed medical assets from MMRP in support of 31st CSH deployment to Operation Enduring Freedom. During that period, MMRP provided more than 60 pieces of medical equipment valued at over $4 million to support the 31st CSH. The most recent use of MMRP was in July 2016, when USAMMA issued three dental medical equipment sets to the 28th CSH, making advanced dental care available to both U.S. and allied forces.

The goal of MMRP is to deliver efficient and sustainable medical readiness. The MMRP ensures four centrally managed CSHs are maintained at a maximum state of readiness for their entire life cycle--from when they are assembled and throughout their usage until they are modernized or divested. To reduce costs where possible, the MMRP focuses on efficiently managing maintenance, inventory, spare parts and storage. When compared with the costs of having to field and sustain all previous active companies and reserve CSHs, MMRP reaps an annual cost savings for the Army of $12.3 million in reduced care of supplies in storage and approximately $500,000 in sustainment costs.

CONCLUSION

Central management of medical materiel makes sense--both in terms of cost control and sustainable readiness. MMRP is a solution that provides greater value to today's Army where resources are limited and readiness is not an option but rather the No. 1 priority.

For more information or questions and details about the MMRP program, contact USAMMA Centrally Managed Programs at 301-619-4462. Or, see SB 8-75-S7 Chapter 6 and Appendix C -- Template for Request for Release of MMRP.

This article was originally published in the January -- March 2017 issue of Army AL&T magazine.

Related Links:

U.S. Army Acquisition Support Center

U.S. Army Medical Materiel Agency

USAASC Flickr January - March 2017 issue of Army AL&T Magazine

Social Sharing