A designer navigates high above the floor moving from room to room adding a pipe here, putting up a wall there and sprinkling the final touches on the building layout that will contribute to millions of dollars in savings.

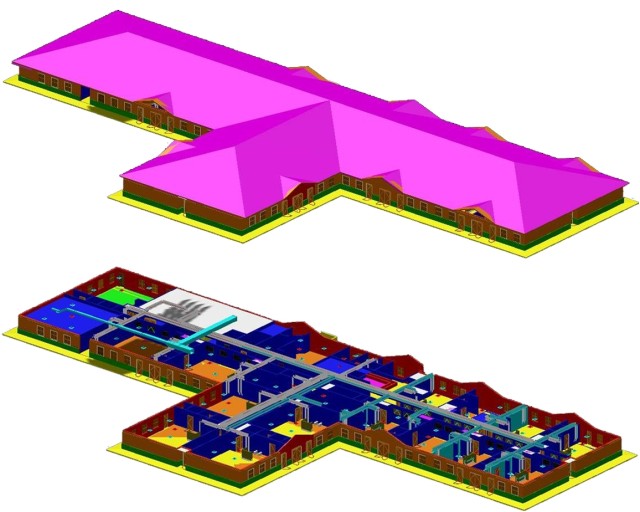

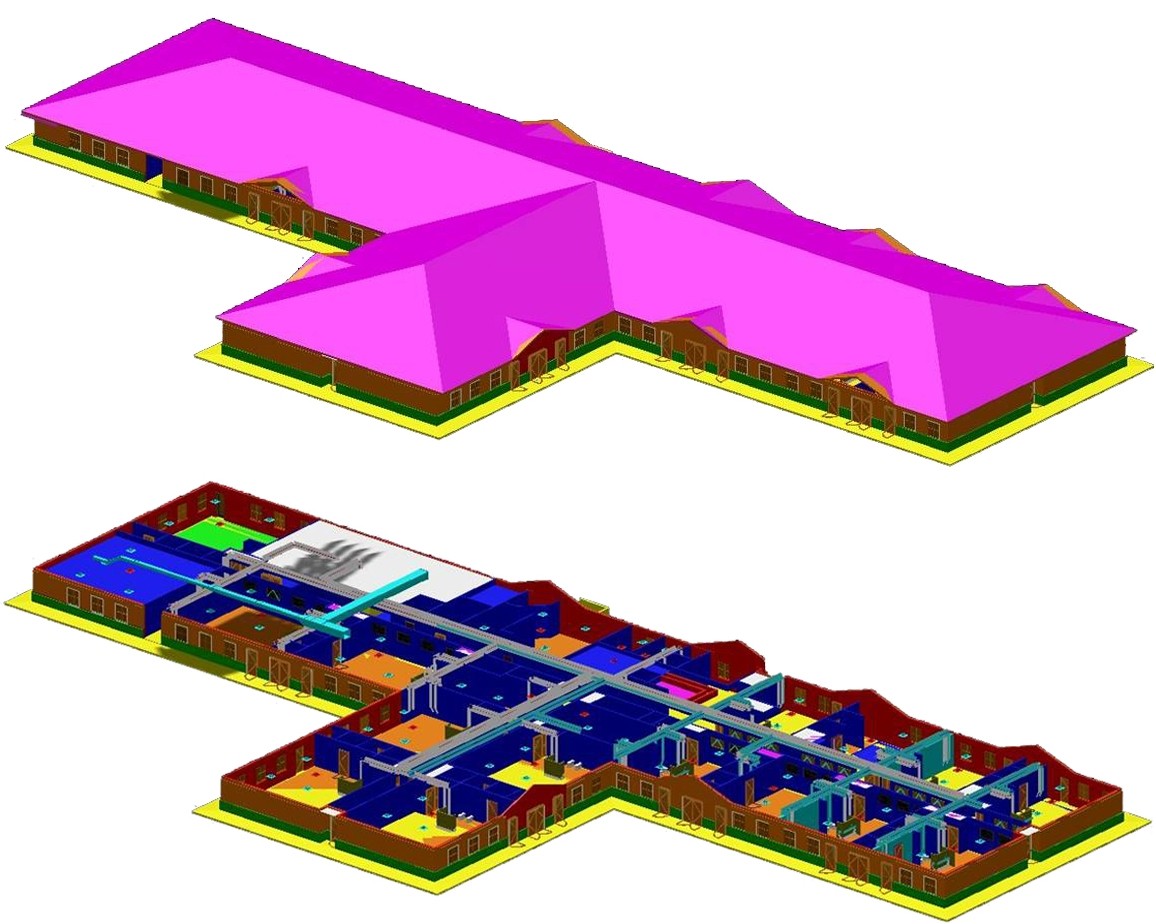

This isn't a new XBOX video game. It is a new 3-D design technology known as Building Information Modeling - BIM .

Through the Military Construction (MILCON) Transformation program, the U.S. Army Corps of Engineers is improving construction time and costs. In order to meet construction deadlines and costs, the Corps is changing existing design philosophies and methods.

For years, the Corps has maintained standard designs on a variety of facility types, such as fire stations, physical fitness facilities and bowling allies. However, these standards are based upon traditional design and construction methods. To improve the design process, the Corps is applying BIM technology in coordination with the existing standard design program.

As a center of standardization, the U.S. Army Engineering and Support Center, Huntsville is updating the child development center standard design to conform to BIM technology.

"To kick off the update, Huntsville Center has initiated a five-week BIM training/coaching effort," said Sandy Wood, a Huntsville Center mechanical engineer who is overseeing the BIM training. "We were tasked with learning the new software and applying it to a medium child development center project. Since BIM contains mechanical, electrical, structural and architectural components, we brought in employees from all four disciplines for the training."

Not only does BIM apply four components of engineering but it also uses intelligent graphics.

"The intelligent graphics feature of the software is very beneficial," Wood said. "This new tool allows us to place a pipe in a design and find all the attributes of the pipe. Each graphic is linked to a database that contains various attributes and reports. Before you would just draw a line to represent the pipe, and you couldn't extract useful information."

BIM also allows the team to see their mistakes before they finalize the design.

"If a designer is unsure of a particular aspect of the design, he can run an interference check," Wood said. "This check will quickly identify any conflicts in the design. Once he sees the conflict, he can easily go back and correct deficiencies."

After only three days of designing the child development center, the team accomplished a large portion of the design, including building compound walls, windows and drop ceilings, and placing storage cubbies in the rooms.

"We kept the design simple and included more aesthetic features based on the customer's input," said James Dunn, lead architect for the child development center design. "With BIM, we can take a project that normally takes four months to design and design it in two months."

Most people on the team said that the software exceeded their expectations, and they agreed that it was very user friendly.

"I really enjoyed taking a project and putting it into a 3-D model," said Mo Bryant, Engineering Department of Army intern. "It also helped that all engineering disciplines were in the same room while working on the project. Being co-located made it easier to deal with problems that arose."

The benefits of BIM don't stop at the design phase; they reach all the way out to

the construction phase.

"Even though design cost is higher with BIM, it eliminates the majority of typical

changes in the field during construction," Wood said. "Change orders usually account for 8 to 12 percent of the cost in a typical design project. A design done with BIM has been proven to reduce change orders to as little as 2 percent of the construction costs. In large dollar projects, this could easily add up to millions of dollars in savings."

Only Corps standard design districts will use BIM for now, but over the next five

years all designs will be done using BIM.

Social Sharing