NATICK, Mass. -- Quoc Truong -- a scientist at the U.S. Army Natick Soldier Research, Development and Engineering Center, or NSRDEC -- has a dry yarn to tell.

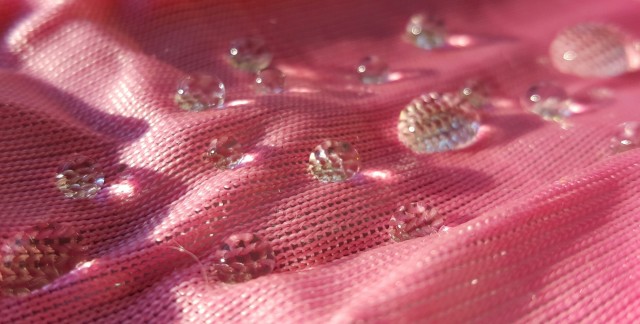

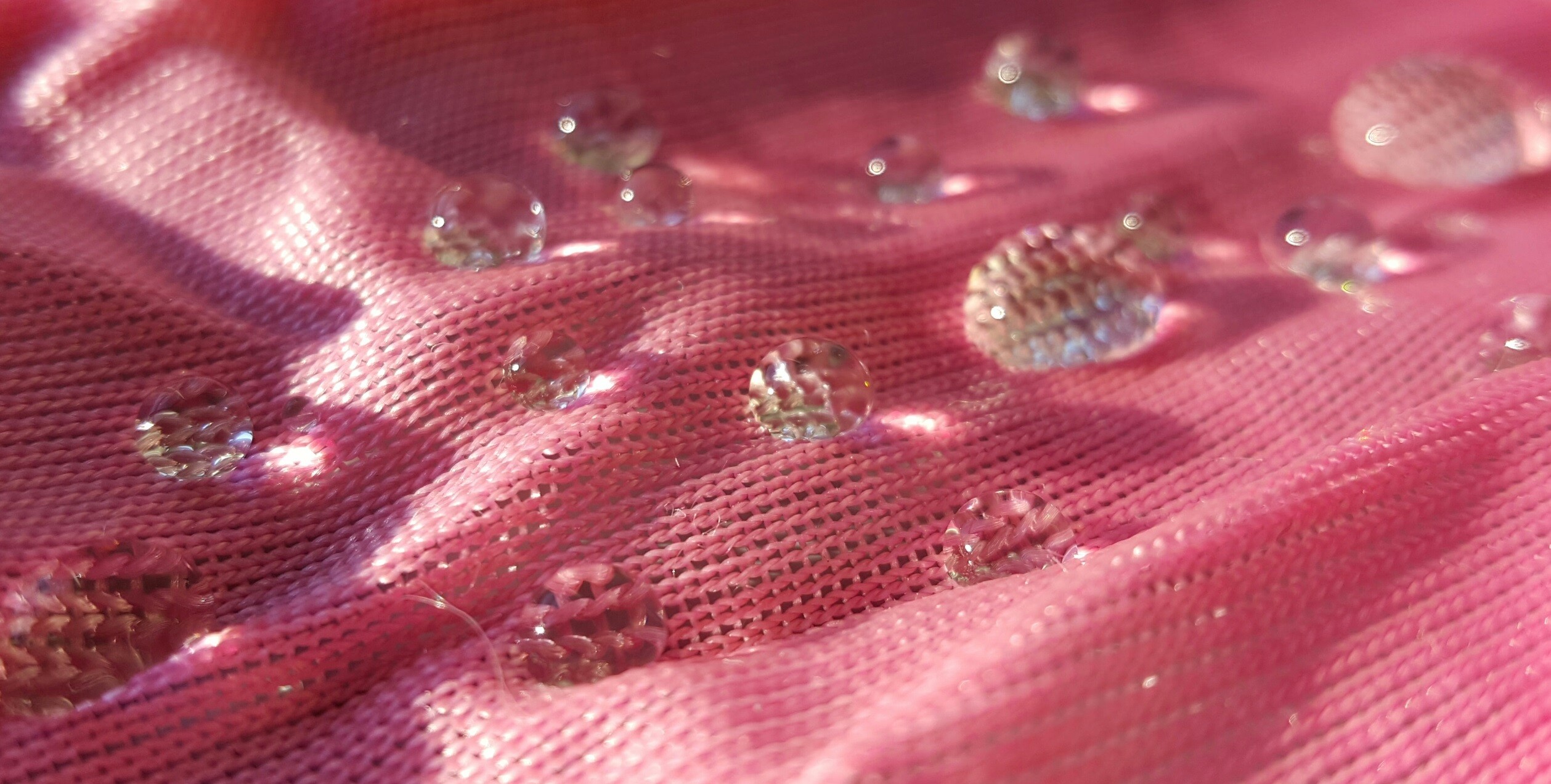

Truong invented a new architecture for super non-wetting fibers, which have channels with re-entrant features in the shape of repeating trapezoids, which represent the optimal shape to repel liquid. The new architecture will take super non-wetting fabrics to the next level.

The resultant fibers mean improved warfighter protection. Since liquid will not wet the fabric, the fibers will help to keep out chemical-biological and other threats, enhancing personal comfort and protection performance. The fibers also keep out oil, chemicals, dirt, and solid contaminants. Thus, the fabric doesn't need to be washed as often.

Truong and NSRDEC are collaborating with Clemson University, University of Massachusetts Lowell, Massachusetts Institute of Technology, or MIT, and Luna Innovations Inc., on the project.

"The new architecture is based on and builds upon an amazing discovery by MIT in 2007," said Truong. "When a surface is engineered to have certain trapezoidal shape nano features at a certain angle, where the contact angle of the contacting liquid is greater than the contact angle of the re-entrant trapezoidal shaped nano features, then the liquid will simply not wet the surface. So at an incline, the contacting liquid will simply roll off the engineered surface."

MIT's findings gave Truong an innovative idea.

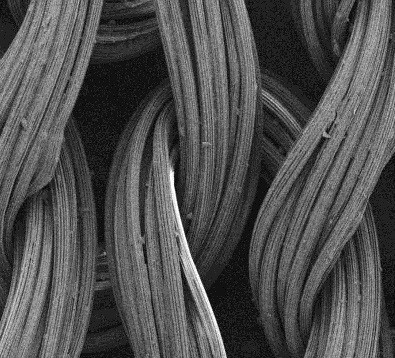

"I thought instead of having a surface feature that is on a flat surface, what if we make it in such a way that the fabric will now be based on the fibers that have a repeating feature all along the length of the fiber," said Truong, "I then talked to the MIT professors Bob Cohen and Gareth McKinley about it. I told them I wanted to create a bi-component fiber in such a way that one component is extractable and one is water soluble.

"So after extruding the bi-component fiber, we subject it to water and the water soluble component is dissolved away. We will then have a certain structure that is very similar to the structure on the flat surface that causes super non-wetting. The finer these re-entrant features become, the more the curvature of the fiber surface will resemble that of a flat surface; hence, the fiber will behave similarly as that of the super non-wetting flat surface."

"The fibers may radically reduce or completely eliminate the need for hydrophobic and oleophobic surface chemistries as well as increase the lifetime of the repellent properties of fibers and fabrics due to their inherent geometrical properties as predicted by the modeling team at MIT," said Dr. Philip J. Brown, materials science and engineering, Clemson University.

"On the surface of the fiber, we put the nanoparticles on top of the surface and inside the channels," said Truong. "This creates the fiber surface that doesn't allow liquid to wet. And, with nanoparticles that are also coated on the inner wall surface of the channels, the contacting liquid will not propagate, or wick, along the fiber's inverted trapezoidal shaped channels. This effectively eliminates the "capillary effect," that is the ability of a liquid to flow in narrow spaces without the assistance of external forces like gravity, along the tiny channels that surround the uniquely shaped fiber.

"When we combine these fibers and weave them into a fabric, that gives us another level of liquid repellency. So what I came up with was creating a special channel substructure around the fiber, and then putting the nanoparticles on top of the fiber and inside the channels. This introduces the fourth level of the re-entrant structure."

"Ideas and concepts like that can be turned into reality and can completely change an industry -- and perhaps only come along once in a hundred years," said Brown.

"We are working to create the fiber re-entrant structure having a specific size and shape to make sure the resulting fabric is super non-wetting," said Truong.

Truong is currently working to eventually get the fibers incorporated into several warfighter uniforms, including uniforms for a tropical/jungle environment and chemical-biological protective clothing.

"The fiber will not allow chemical agents to wet the surface of the protective clothing," said Truong. "And since the agents don't wet the surface, they just roll off instead of permeating through and causing harm."

The non-wetting fibers will also be beneficial in cold environments.

"The fiber will help prevent frostbite because it is extremely dangerous to be wet in cold temperatures," said Truong.

The fibers have potential commercial applications.

"We have new reasons for creating multi-functional textiles because consumers have come to expect and appreciate improvements in comfort, fashion and functionality," said Brown.

The fibers could be used by commercial workers who handle chemicals, work in the rain, work in extreme cold, or even by athletes.

"For example, just imagine if Michael Phelps swam in a swimsuit made of this fabric; he would swim even faster," said Truong. "Because the fabric doesn't get wet, the drag resistance in the water is very low. He would go through the water like a speeding bullet."

At the end of the day, however, Truong is grateful for the chance to improve protection and quality of life for the Soldier.

"I feel very fortunate to have this opportunity to help the Soldier," said Truong. "That's all I ever wanted to do since I arrived here from Vietnam years ago. I have an opportunity to repay the kindness I was shown."

-----

The U.S. Army Natick Soldier Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission is to provide innovative research, development and engineering to produce capabilities that provide decisive overmatch to the Army against the complexities of the current and future operating environments in support of the joint warfighter and the nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Links:

U.S. Army Natick Soldier Research, Development and Engineering Center

Social Sharing