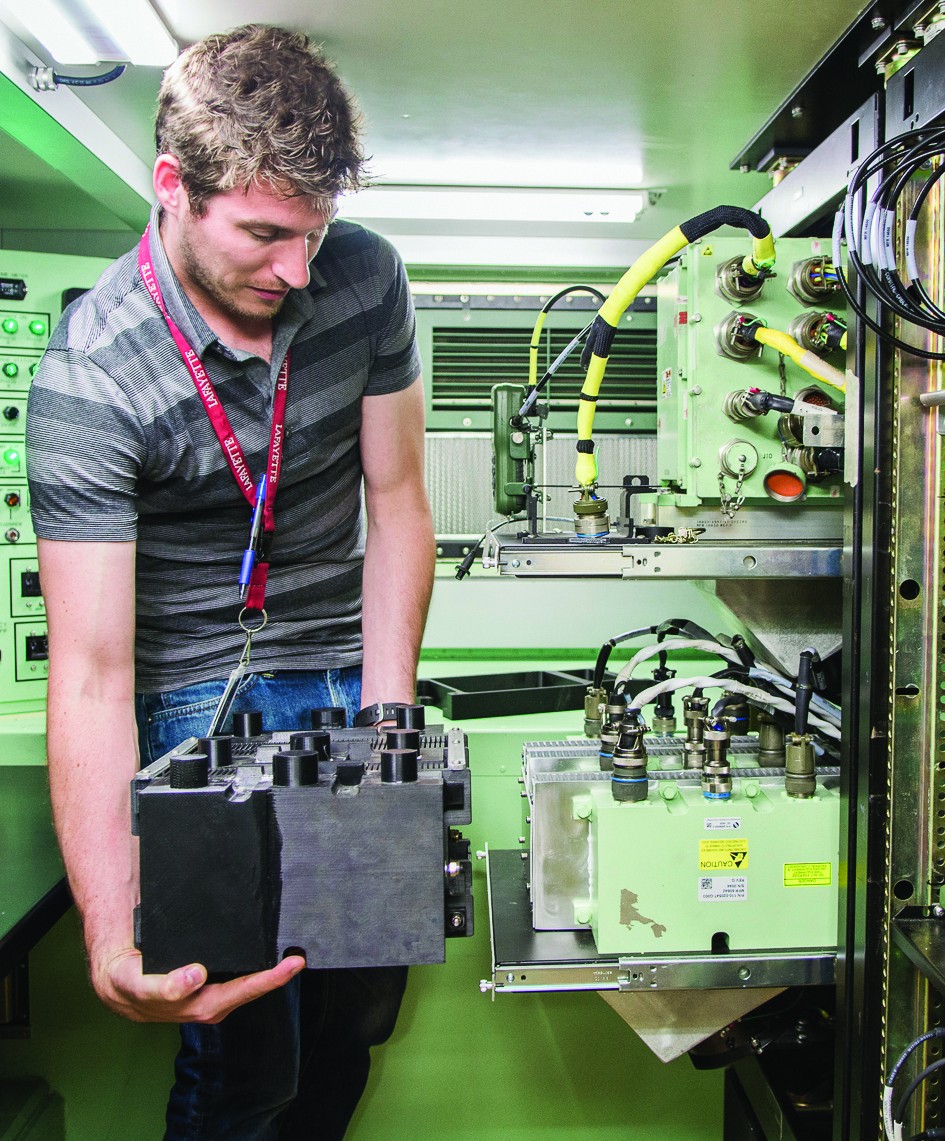

TOBYHANNA ARMY DEPOT, Pa. -- Mechanical Engineer Brian Thomas shows how a 3D-printed replica of a power supply looks exactly like the real thing.

The model was used to help Tobyhanna personnel make design modifications while waiting for the actual components to arrive on the depot. Thomas works in the depot's Design Development and Fabrication Division.

With the use of computer aided engineering, Tobyhanna Army Depot can offer additive manufacturing services.

Personnel here use a variety of systems which reduces setup time, develops complex designs and creates multiple parts in one run. These services save money while encouraging modifications, new development and enhanced trouble-shooting analysis.

Laser scanning and 3-D printing helps design engineers produce engineering models, reverse engineer products and validate the design to manufacture products in days rather than weeks.

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for command, control, communications, computers, intelligence, surveillance and reconnaissance systems across the Department of Defense.

Tobyhanna's Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C4ISR provider of choice for all branches of the Armed Forces and industry partners.

Social Sharing