FORT BLISS, Texas (Army News Service) -- Capt. Jonathan Janiszewski doesn't want to be accused of crying wolf. But he might have been in the past, at least by some Soldiers.

As an Air Defense Airspace Management, or ADAM, officer, Janiszewski and his team monitor airspace for 2nd Brigade Combat Team, 1st Armored Division at Fort Bliss. They're participating in the two-week Army Warfighter Assessment 17.1 that began Monday. The exercise is meant to gather feedback from Soldiers on the performance of new warfighting capabilities.

Among the many roles of the ADAM team is to monitor the sky for incoming airborne threats -- rockets, artillery, and mortars for instance -- and warn Soldiers in the brigade combat team that they ought to take cover.

Right now, Janiszewski says, when his team senses such a threat, they send out alerts to warn everybody. But that's the problem -- not everybody is actually in danger. And when Soldiers are warned too often of impending doom from the sky that never comes, they can get complacent. And that's dangerous, too.

At the AWA 17.1, Janiszewski and his team are trying out a software upgrade for their existing Air Missile Defense Workstation and Forward Area Air Defense system. The software allows his team to warn specific Soldiers -- the Soldiers who would actually be hit -- so they can take protective measures.

It's called, "Leader Effects Tool Suite and Localized Warn to the Edge Capability," or "LETs Warn" for short.

"So, we're not crying wolf," he said "We're informing the exact individual who is going to be impacted by that threat, of that threat, and that allows them to react accordingly. It allows those Soldiers to take cover, get inside hardened shelters."

In addition to warning just those Soldiers who will be affected by the impending impact of an attack, LETs Warn also ensures that others who aren't in immediate danger receive an advisory or situational awareness-type message.

"We're only warning the individuals affected by that threat," Janiszewski said. "As a result, we end up with a situation where everyone else continues to maneuver. Adjacent units continue their mobility, their attack, whatever it is they are in the midst of executing."

At AWA 17.1, the ADAM team will use the LETs Warn system to alert Solders to air strike warnings. Soldiers will receive those messages on either Joint Battlefield Command Platform/Joint Capabilities Release systems or the Nett Warrior system.

"If you tell somebody over and over they are about to take fire, and they never actually receive fire because it lands two miles away, then it desensitizes the Soldier," Janiszewski said.

"We're saving lives because we send the right message to the right people at the right time."

PRINTING A TANK TREAD

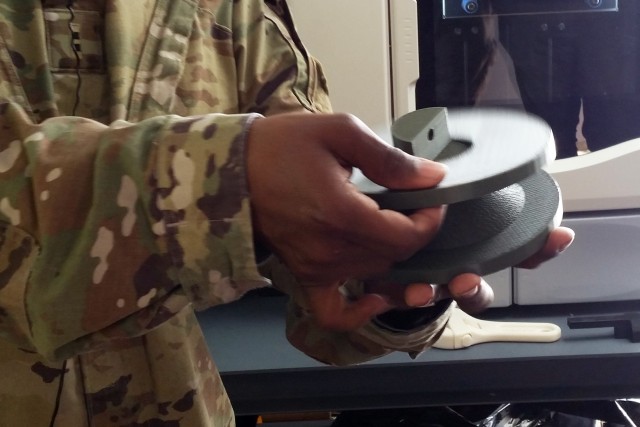

Chief Warrant Officer 2 Ron Billingslea is an allied tradesman with the 47th Brigade Support Battalion, part of the 2nd Brigade Combat Team, 1st Armored Division. He oversees the fabrication of wood and metal projects to support his brigade. At AWA 17.1, he's got the ability to work in plastic, too.

Billingslea is assessing the Rapid Fabrication via Additive Manufacturing on the Battlefield system, or R-FAB. The R-FAB amounts to a mobile container with an array of 3-D printers on board that allow him to fabricate plastic parts on-demand for Soldiers in the brigade.

"As allied tradesmen, this is one of the biggest tools we've been waiting on for a couple of years," Billingslea said. "This, along with the Metal Working and Machine Shop Set, will give us a full-circle of what we can possibly do."

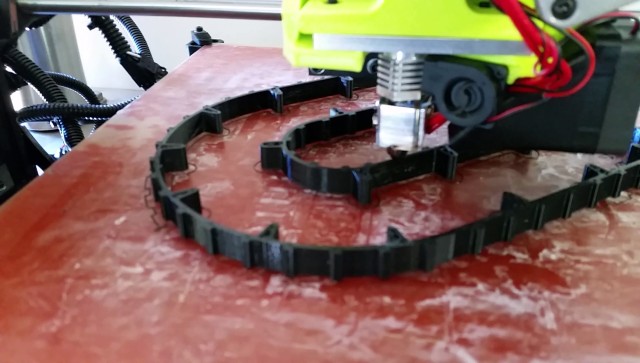

Inside the R-FAB, Billingslea has the handful of 3-D printers grinding away, extruding plastic to manufacture parts he thinks brigade Soldiers will need during the AWA. One printer was producing plastic washers while another produced treads for robotic ground vehicles.

The 3-D printers themselves are commercially available and are not the focus at AWA 17.1. The focus is assessing how having those devices on hand help him better serve the bridge.

"Soldier readiness and Soldier innovation," are the goals of the system, Billingslea said.

Getting started, he said, when they first set up for AWA 17.1, they found they had a generator but no tool to lock down the grounding rod.

"So instead of using a normal socket wrench or monkey wrench, where we'd have metal-to-metal contact, we came in and printed out a plastic wrench," he said. "It took us a couple hours to make it, but we were able to ground our generator."

Using 3-D printing, they also came up with a device to allow Soldiers in the motor pool to open 55-gallon drums. Soldiers had been using hammers and screwdrivers to pound away at the lids on the drums, in an attempt to open them, Billingslea said.

"We came up with a way to carbon-inlay a tool to just push in a little, apply some pressure and it opens perfectly fine."

Billingslea said his team is also working now on a "skid" they could manufacture on-site that will allow radios to be removed quickly from combat vehicles in the event that Soldiers need to evacuate.

Capt. Jeremy R. Pinson, of Combined Armed Services Command, who was also inside the R-FAB, said when a Soldier needs a part, such as a tread for an autonomous robotic ground vehicle, they can manufacture it on-demand with the R-FAB, but they will still order a replacement. While it may take 12 hours for the part to arrive, a temporary part could be printed in 10 hours.

With the ability to manufacture just about anything, it may seem as though ordering replacement parts would be a thing of the past. But for now, 3D-printed parts will serve as a novel stop-gap solution for the period between when a part breaks and when a replacement part arrives, rather than a permanent substitution.

Pinson said there remains one hurdle to that concept of operations: intellectual property. Manufacturers often own the design patents on the parts inside the machines they sell the Army, which means the Army can't simply manufacture new parts in lieu of purchasing parts from the manufacturer.

Pinson said the Army is currently looking for a model to make good use of the 3-D printing capability while also ensuring manufacturers are compensated for their intellectual property.

Before AWA 17.1 began on Monday, Billingslea had already found one flaw in the R-FAB system: a camera used to model real-world objects in 3-D so they can be modified and manipulated in computer design software and then printed.

The camera was not rugged enough for the combat environment.

LEAD, FOLLOW OR GET OUT OF THE WAY

On a dirt road outside the 47th Brigade Support Battalion camp here, Capt. Octavia Heningburg described the synchronized ballet of Palletized Loading System vehicles that lumbered down the road, kicking up dust. The two PLS vehicles were equipped with a "Leader/Follower" system that allows one vehicle to follow the other, without needing a driver.

Whatever the first vehicle does, Heningburg said, the second vehicle "will do the same thing. If it stops, the second vehicle stops."

The Army thinks the system might be great for convoy operations. Where a five-vehicle convoy might need 10 Soldiers, two in each vehicle, "Leader/Follower" would mean they need only two drivers. The lead vehicle would have two live drivers, while the next four "follower" vehicles would be driverless and simply follow the lead vehicle's every move.

At the demonstration at Fort Bliss, there was actually a person in the second vehicle, though Heningburg said he wasn't touching the steering wheel. He was just there for safety, she said.

"His hands, during this demonstration, are going to be outside the vehicle, to demonstrate that he is not moving this vehicle," she said. "It's getting control based on the first vehicle."

Each Leader/Follower vehicle can be programmed to be either a leader or a follower, as needed. The vehicles are equipped with features normally found on today's high-end passenger vehicles like collision-mitigation braking, lane-changing assist, backup warning, and backup-assist.

The system also notifies drivers to danger with visual and audio alerts. If the driver doesn't take action, the system can apply brakes and steering to avoid accidents.

At Fort Bliss, as part of the AWA 17.1, five Palletized Loading System vehicles were equipped with Leader/Follower capability, and two additional Humvees were equipped as "command" vehicles.

The vehicles could all actually operate driverless -- with the "leader" vehicle taking direction from GPS-cued waypoints rather than a Soldier operator, according Maj. Mark A. Gesky, of Army Capabilities Integration Center.

But he said Leader/Follower is the near-term goal. Adopting the system could increase Soldier safety, because with vehicles that drive themselves, fewer Solders will be on the road and in harm's way.

"It's a force protection issue, primarily," Gesky said. "We can take Soldiers out of vehicles that are less protected and transfer them into better-protected vehicles, whether that be mine-resistant ambush protected vehicles or other up-armored vehicles."

And when a commander discovers he needs fewer Soldiers as drivers on convoy operations, that means those Soldiers can be used elsewhere, to support other missions.

"It'll increase our throughput capability," he said. "With the same [number] of people, you can do more operations. You don't' have to worry about crew rest."

UNDER EVALUATION, DOCTRINALLY SOUND

As with every capability under evaluation at the AWA, Soldiers will be asked to provide feedback on the Leader/Follower system, said Col. Charles Lombardo, 2d Brigade Combat Team, 1st Armored Division. The 2nd BCT has been at Bliss, and involved in past Network Integration Evaluations since 2011.

Lombardo said AWA 17.1 will be their last such assessment, as they are reintegrating into U.S. Army Forces Command rotations. But for now, he said, his brigade is well-versed in assessing the impact of new equipment like the Leader/Follower system, the LETs Warn, the R-FAB, or any of the 41 concepts and capabilities under evaluation.

"It's not only what we take forward, it's what we don't take forward," he said. "And with the Soldiers here, working it at the ground level, you get very frank, honest feedback at the user level, which you may not always get if you don't have an active brigade actually testing this."

Starting in June and all the way though the kick-off of AWA 17.1 Monday, Lombardo and the Soldiers in his brigade went through "doctrinal integration" of the concepts and capabilities that would be assessed at AWA 17.1.

"We kind of study what [Army Training and Doctrine Command] is thinking about, and how they want to employ [a capability]," he said. "We match that to our current doctrine, so we are doctrinally sound … [and] we employ it in the correct manner."

Lombardo noted that the AWA will be stopped three times so that Soldiers can provide their feedback to data collectors from Brigade Modernization Command -- which runs the AWA -- and the Army Test and Evaluation Command, the Army Capabilities Integration Center, Army Training and Doctrine Command, and others.

"This is Soldiers providing frank feedback to the data collectors," he said. "It's unfettered. People aren't editing that. It's from the Soldiers."

Social Sharing