PICATINNY ARSENAL, N.J. -- If flares are like fireworks illuminating the battlefield, then members of Picatinny Arsenal's Pyrotechnics Division are about to launch the big finale.

Their latest project focuses on improving the chemical composition of the M127A1 White Star Parachute Handheld Signal, so that it burns brighter and covers more area with effective illumination than its predecessor.

An illumination flare is a type of device that produces light and/or heat without an explosion.

They are often used in the military as a way to light the battlefield and visualize nighttime targets or to signal other warfighters.

They can be launched from rockets, artillery, mortars, aircraft, or handheld devices like the M127A1.

"This idea brings two advantages to the warfighter," said Rashmi Mangal, the ARDEC Tunable Pyrotechnics project officer, about the M127A1 project.

"You have a brighter candle and the potential for a smaller, lighter handheld signal that the warfighter needs to carry," she added.

The project is a science and technology funded project at the Armament Research, Development and Engineering Center, or ARDEC.

It is managed under the Tunable Pyrotechnics program in ARDEC's Pyrotechnics Technology and Prototyping Division.

Mangal is in charge of the Tunable Pyrotechnics program, which oversees multiple projects, including handheld signals, countermeasures, and environmentally-friendly pyrotechnics.

One of the program's former projects involved removing toxins in rounds and replacing them with an environmentally benign composition.

The new composition could be potentially placed in incendiary projectiles, which are fired from military weapons such as the M2, M3, and M85 machine guns.

The M127A1 is a single use illuminant device managed by the Project Manager Close Combat Systems, or PM CCS, an office within the Arsenal's Program Executive Office Ammunition. Some other PM CCS products include countermines and explosive ordnance disposals, improvised explosive devices, area denial, combat munitions, such as grenades or non-lethal ammunition and support munitions, such as demolitions and pyrotechnics.

Typically, the M127A1 is used for non-verbal communication between troop emplacements and battlefield illumination. The flare composition in this particular device burns to produce a bright white to yellow flame. Moreover, the M127A1 flare is parachute-suspended and propelled by a fin-stabilized rocket motor, which is all contained in a 10-inch aluminum tube, weighing about 1.2 pounds.

LUMINOUS INTENSITY

"Originally, the main goal for this project was to improve the brightness of a flare by at least 50 percent without compromising any burn time," explained Jared Moretti, a chemist who serves as the team's integrated product team lead.

The brightness of a flare is measured in candela, the SI base unit for luminous intensity. For example, a common candle emits about 1 candela, while a 25 watt fluorescent bulb will emit about 135 candela (assuming the light is distributed equally in all directions).

According to the pyrotechnics team, the minimum function requirements for the M127A1 was a burn time of 25 seconds and a light emission of about 90,000 candela. The previous M127A1 composition met those requirements with a typical burn time of about 30 seconds and a typical maximum emission of 125,000 candela.

However, the improved M127A1 burns for 29 seconds and reaches about 150-160,000 candela, meaning it's approximately 75 percent brighter than the current minimum requirement.

This performance enhancement was induced by changing to a different flare composition called M127E2, which relies on a smaller magnesium granulation. This new composition is manufactured in the same way as the old composition.

The improved handheld signal will require no additional training for warfighters. As added benefits, it can potentially be used in future, smaller handheld signals, and any increase in unit cost will be negligible.

"We had tried a variety of high-nitrogen compounds, and we weren't able to achieve the target objective," said Moretti. "So, we switched gears and resorted to a smaller magnesium particle size. That's what's so remarkable. You change just the size of the one ingredient and you get massive increase in performance."

Additionally, the former M127A1 uses Laminac, a polyester binder that holds the flare together. But, this binder is usually manufactured by only one single point failure company and it can be difficult to obtain, explained Moretti.

For that reason, the improved device uses a two-part epoxy binder, which has a long service history in mortars and artillery rounds and is environmentally benign.

"Basically, you have a M127 candle that is filled with this formula, and that is connected to a parachute," explained Dan Colotti, a chemical engineer. "This assembly is in a payload that is then placed into a rocket. The rocket shoots up to about 800 feet--ts hand initiated. Then, you deploy and ignite the payload and the parachute opens. It floats up, it descends, and illuminates the battlefield."

COMPOSITION DEMONSTRATION

The improved M127A1 project was initiated in 2011 by the U.S. Army Environmental Quality Technology Pollution Prevention program. The organization's goal was to change all military handheld signals by using more environmentally friendly compositions, such as many of the red, white, and green star handheld signals developed at Picatinny.

"White handheld signals were part of that same initiative, where we had to come up with non-toxic substances," explained Mangal. "But, when we started to do research, we found an added benefit of getting the signal to be 75 percent better than the requirement. So, we have met the environmental requirement, but also have accomplished an additional performance capability."

The Pyrotechnics Division has tested the new composition in various demonstrations, including static (in a lab) and dynamic tests. One of these demonstrations was held last year in Somerville, Tennessee, at Security Signals, Inc. (SSI), the prime handheld signal manufacturer. SSI's role in this effort was to produce the illuminant composition and full up signals to specifications and test them in accordance with the test plan.

During this system demonstration, Picatinny's Pyrotechnics Division tested 126 signals filled with the M127E2 composition in four different environmental conditions: hot, ambient, cold, as well as transportation/vibration.

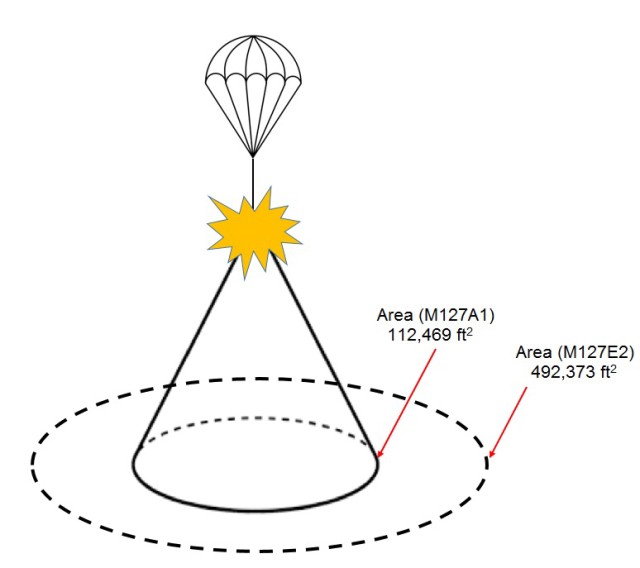

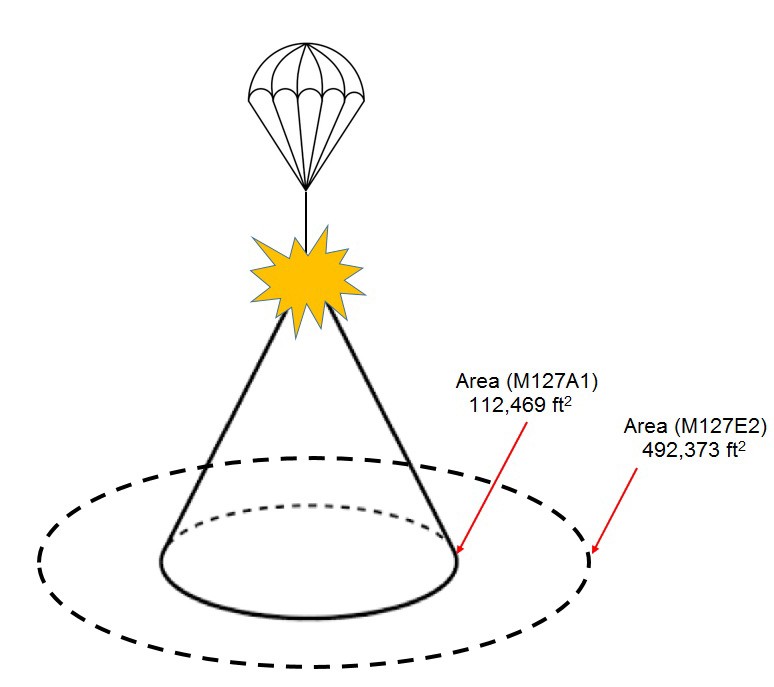

Along with having no testing failures, the system demonstration revealed that the burn time exceeded the threshold requirements, ranging from 26.5 to 29.8 seconds of burn time. It also showed that the former composition exhibited a brightness that could project across a ground area of about 112,469 square feet. But, the new composition projected an effective ground illumination that could reach 492,373 square feet, making it more than 300 percent more effective in illuminating the ground area.

"The M127E2 provides better illumination over the original illumination round," said Sgt. Maj. James M. Carroll, a TRADOC capability manager, who witnessed a more recent user demonstration onsite at SSI. "We must analyze the effects of this new round with current and near-term technologies and nest it within our Soldier Modernization Strategy."

Currently, Picatinny's Pyrotechnics Division is done with testing and ensuring that the new composition meets all the Army's energetics material qualification requirements. When it was completed, the M127E2 had achieved TRL 6 and was transitioned to PM CCS.

The team is exploring an initiative to place the new composition into a family of logistically enhanced smaller handheld signals by re-examining their weight, geometry, and overall performance requirements.

"If we can do one as an example, then there are eight others in the family of handheld signals to which we could adapt the reduced-size technology," said Mangal.

"So, we think this might be a start to another big change in the era of handheld signals."

-----

The U.S. Army Armament Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing