ABERDEEN PROVING GROUND, Md. -- The culmination of innovative thinking focused on conservation and sustainability was realized, July 19, during the official opening of the new Combined Heat and Power plant, here, on APG South (Edgewood).

The product of the Energy Saving Performance Contract project #8 replaces the capabilities of the local Waste-to-Energy plant and supports crucial Army research and development and chemical/biological facilities located on APG South.

APG Senior Commander Maj. Gen. Bruce T. Crawford, commander of the U.S. Army Communications-Electronics Command said the passion and dedication that went into the project was impressive.

"It's not just a passion for saving money, it's not just a passion for energy, but a passion for things like innovation. As I've said many times, the thing that concerns me most is if we don't come together to collaborate, we miss opportunities."

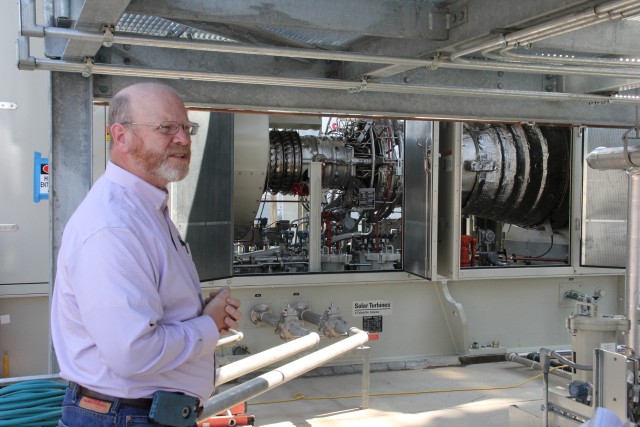

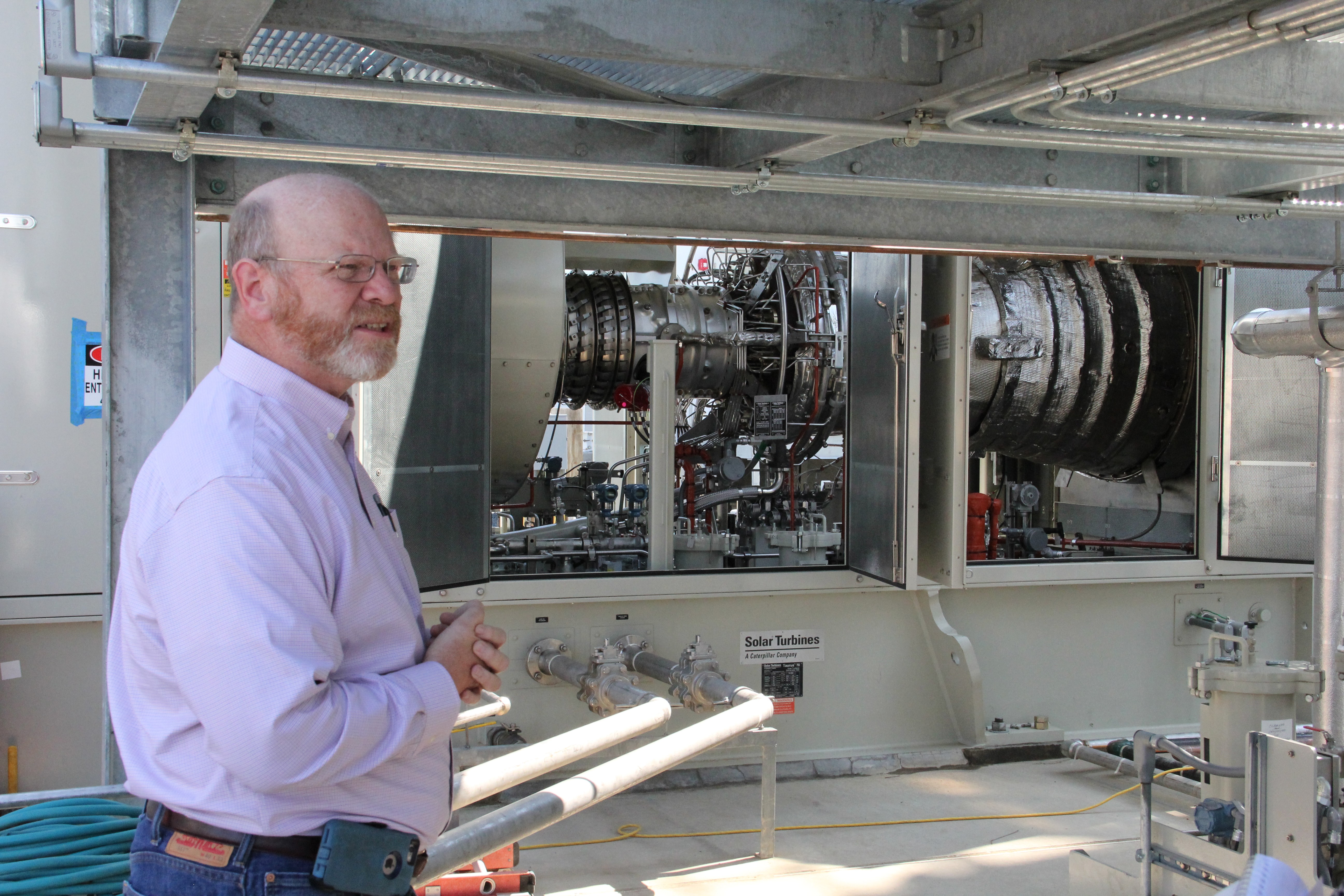

When the steam supply contract between APG and Harford County, Maryland ended in March 2016, APG mission activities required an alternate solution, explained Installation Energy Manager Devon Rock. The CHP plant, an emerging new technology, will generate high-quality electricity and steam for Edgewood far exceeding traditional equipment in terms of energy efficiency and emission reductions, she added.

"One of the most critical roles of Army Energy Managers is to develop the most economic and sustainable solutions possible to ensure mission readiness," she added. "The electricity and steam from this CHP plant will be used throughout the Edgewood area to provide state-of-the-art laboratories with specific temperature and humidity controls for Army research and development organizations such as the Edgewood Chemical and Biological Center, ECBC; Public Health Center, or PHC; and the Medical Research Institute of Chemical Defense, MRICD."

Rock said the effort was achieved through collaborations with the Huntsville Corps of Engineers and energy saving partnerships with defense contractor Johnson Controls and Baltimore, Gas and Electric.

Representatives on hand from stakeholder organizations included Cecil Rodriguez, deputy administrator, Region 3 of the Environmental Protection Agency; and Kathleen Hogan, deputy assistant secretary for energy efficiency from the Office of Energy Efficiency and Renewable Energy.

Rodriguez said the system requires less fuel to produce the same amount of energy and that the partnership was the greatest example of resource management and attaining Net Zero consumption. Wayne Harbaugh, BGE director of Energy Efficiency presented a $2.5 million check, representing long-term cost savings, to Crawford and CECOM Command Sgt. Maj. Matthew D. McCoy.

"A combined heat and power facility turning what might otherwise be waste-heat into power is innovative," Harbaugh said. "It's my honor to present Aberdeen Proving Ground with a check for $2.5 million from the BGE Smart Energy Savers Program. Thank you for being a partner in energy innovation and for inspiring all of us to follow your lead."

The ceremony, which culminated with a ceremonial chain-cutting followed by tours of the plant and other facilities managed by the APG Garrison's Directorate of Public Works.

The CHP plant is located at Bldg. E-5126. The project fully replaces the capacity of the WTE plant and generates about 50 percent of the current Edgewood electricity load. This improves APG's energy security posture for electricity and steam and can be quantified by nearly $4.4 million in electrical savings, annually.

"This is yet another great day in the storied history of this installation," Crawford said, adding that the overall savings will exceed $25 million over the next several years. In addition, he said it speaks to the Army Chief of Staff Gen. Mark A. Milley's #1 priority: Readiness.

In the Army Readiness Guidance, Calendar Year 2016-17, under Army Readiness Priorities, Strategic Readiness, part 5 stipulates: "Improve our ability to project national power quickly by optimizing our Army's prepositioned stocks; implementing expeditionary mission command systems and concepts; training/evaluating unit, installation and Army-wide processes through Army Emergency Deployment Readiness Exercises and ensuring installation power projection platforms are well maintained."

"A big part of the readiness conversation is Installation Readiness, and I think that this is a good example," Crawford said. "It's a model of what happens when you bring together like-minded individuals with like goals. Absolutely it's about readiness.

"The other takeaway is what happens next," he continued. "There are relationships at work here that did not exist. The real innovation is the long term and enduring capabilities. I'm excited about the savings and the energy efficiency, but I'm more excited about the opportunities that now exist.

"Most importantly, when you look in the eyes of those who put this together, there's a sense of pride and accomplishment because they've created something that's going to benefit the great state of Maryland and the U.S. Army, but ultimately it's going to become a model that's going to benefit the nation."

Related Links:

U.S. Department of Energy, Office of Enery Efficiency & Renewable Energy

U.S. Army Engineering and Support Center, Huntsville

Environmental Protection Agency, Region 3 (Mid-Atlantic)

Additional photos from the APG Combined Heat & Power Plant Chain-Cutting Ceremony

Social Sharing