If you are in the Army, there is a very good chance you have worked and lived in a tent.

Army tents are a way of life in the field, used for living quarters, work space and even dining facilities. In Army Medicine, tents are also used to construct aid stations and field hospitals, providing wounded and injured service members a place to receive immediate and often life-saving medical care.

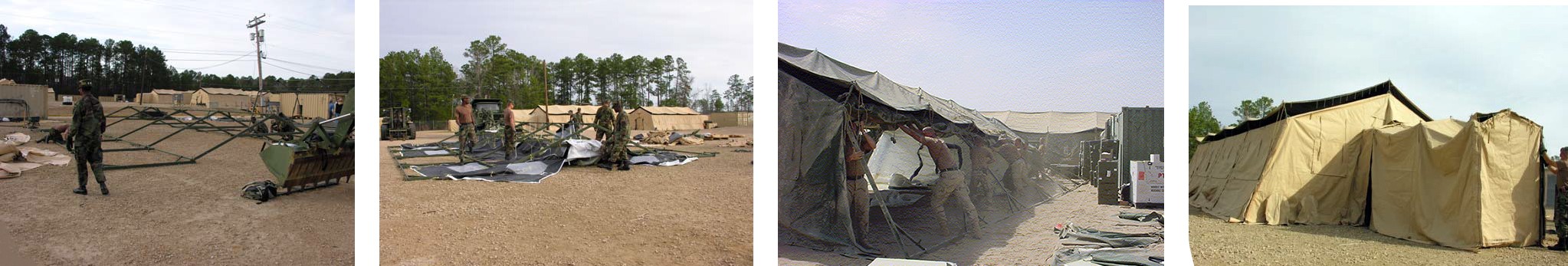

For decades, the tents used to configure these medical facilities were TEMPER (Tent, Extendable, Modular, Personnel) rigid frame tents. While the tents did the job, they were heavy and cumbersome to set up. Additionally, a 2011-2014 study conducted by the U.S. Army Natick Soldier Research, Development and Engineering Center demonstrated that 54 percent of tested TEMPER lots -- many of which had far exceeded their originally designed lifespan--no longer met flame resistance requirements. The U.S. Army Medical Materiel Development Activity-funded study led to the Tank-automotive & Armaments Command (TACOM) Life Cycle Management Command issuing a ground precautionary action message in 2014, to notify units of the safety issue with those TEMPER tent lot numbers.

"Shelters have built into them a flame resistance requirement," said Jaime Lee, product manager for Medical Support Systems Project Management Office at USAMMDA. "It needs to be able to not catch on fire easily and self-extinguish quickly. Since our shelters are so old, a majority of them no longer pass this test and it can create a serious safety concern."

Army Medicine needed new medical tents -- but not necessarily new versions of the same old tents.

The U.S. Army Medical Materiel Agency and USAMMDA, both subordinate organizations of the U.S. Army Medical Research and Materiel Command, teamed up to purchase new TEMPER air-supported shelters. These shelters were developed by USAMMDA over the past decade to replace aging rigid frame shelters. The TEMPER air-supported shelters are 50 percent lighter than the old tents, saving units 17 tons for each 148-bed field hospital. The air-supported shelters can be erected by four Soldiers in about 15-30 minutes, which is 85 percent quicker than the older medical tents that can take more than an hour to set up. In addition, new solar shades that reduce solar loading by 90 percent along with thermal liners are being purchased with these air-supported shelters, which will impact energy efficiency and comfort levels inside the shelter.

Another benefit of the air-supported shelters is that they have a longer operational lifespan than the older tents. The air-supported shelters are projected to last at least 15 years -- five years longer than the older tents--which will ultimately cost the Army less in long-term maintenance and replacement costs.

Some soldiers may have already seen or used air-supported shelters. During Operation Iraqi Freedom and Operation Enduring Freedom, Project Management (PM) Force Sustainment Systems deployed air-supported shelters to replace their aging framed tents used for rest and relaxation requirements.

USAMMA and USAMMDA are working through the Defense Logistics Agency to purchase and field the tents, which should start arriving to units in late 2017. Among the first units to receive the tents will be the Army Prepositioned Stock and stateside-based field hospitals.

According to Lee, USAMMA and USAMMDA also worked very closely with U.S. Army Natick Soldier RD&E Center; Capability Developments Integration Directorate of the U.S. Army Medical Department Center and School, Fort Sam Houston, Texas; PM Force Sustainment Systems, Natick, Massachusetts; Combined Arms Support Command, Fort Lee, Virginia.; USAMRMC headquarters; Office of the Surgeon General; and the HDT Global contracting office to accomplish this feat.

"Whether supporting early entry operations or while sustaining ongoing missions, every pound and every cubic foot counts," said Col. David Gibson, USAMMA Commander. "Fielding equipment and materiel that is lighter, smaller, or more easily sustained is the key to simplifying and improving support on the battlefield."

Social Sharing