ABERDEEN PROVING GROUND, Md. (May 23, 2016) -- Army researchers are exploring options for the next generation of lightweight ceramics for dismounted Soldier protection.

Dr. Lionel Vargas-Gonzalez, U.S. Army Research Laboratory's Ceramic Systems team lead, hosted Anthony Nickens, vice president of Ceramatec Inc., at the Rodman Materials Research Laboratory to discuss the synthesis and processing of boron suboxide, or B6O, a super-hard ceramic material.

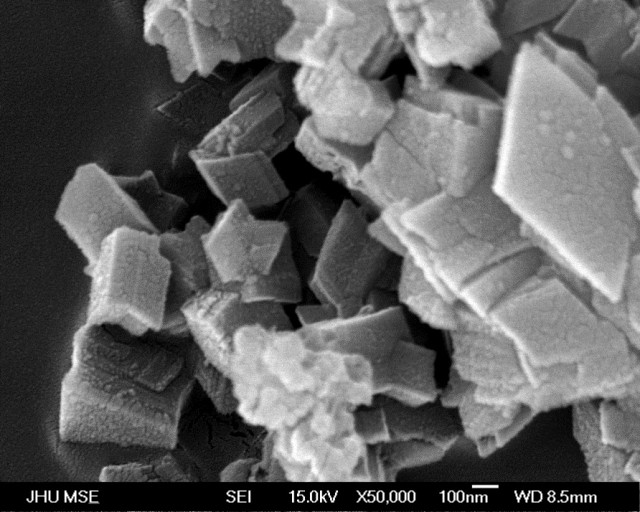

According to an article in Applied Physics Letters, B6O has been of "considerable scientific interest in studies because it displays a range of outstanding physical and chemical properties, such as great hardness with low density, high thermal conductivity, and high chemical inertness."

B6O has generated a lot of interest and investment within the Army science and technology community, Vargas-Gonzalez said. The desired end state of the laboratory's Materials Research Campaign is to enable the Army of 2030 and beyond to succeed in distributed operations and increasingly complex environments through the realization of superior materials.

"B6O is one of several super-hard ceramic chemistries, which have shown potential toward meeting the Army needs for higher mass-efficiency," Vargas-Gonzalez said. "Investments in boron carbide (B4C) and silicon carbide (SiC) have yielded exceptionally great Soldier protection systems for the Army."

Current Soldier armor systems work so well, Vargas-Gonzalez said, that developing new breakthroughs in ballistic performance and mass-efficiency have been "increasingly challenging for Army researchers."

"It leads us to explore new materials and new approaches, which are ultimately high risk, but could lead to huge payoff if successful," he said.

As Army researchers push toward unprecedented levels of ceramic armor performance, the focus has shifted from B4C and SiC toward synthesis and processing science of novel super-hard ceramics, such as B6O and aluminum magnesium boride (AlMgB14).

"These ceramic chemistries exhibit impressive hardness with low density, but have not been pursued for armor applications," Vargas-Gonzalez said. "One reason is due to the scarcity of source powders at commercial scale, leading to high costs. Another is the high level of difficulty in processing these materials into theoretically dense armor-grade plates."

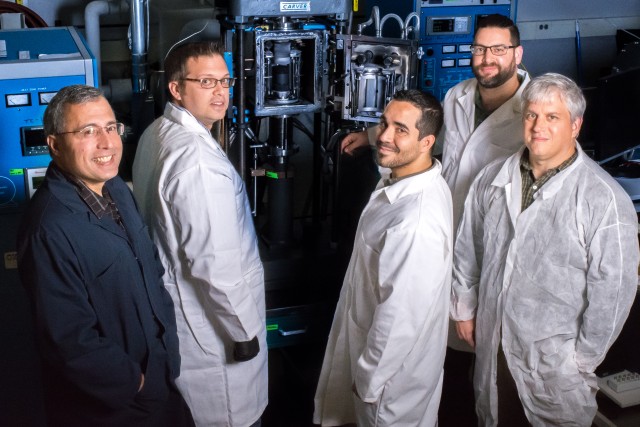

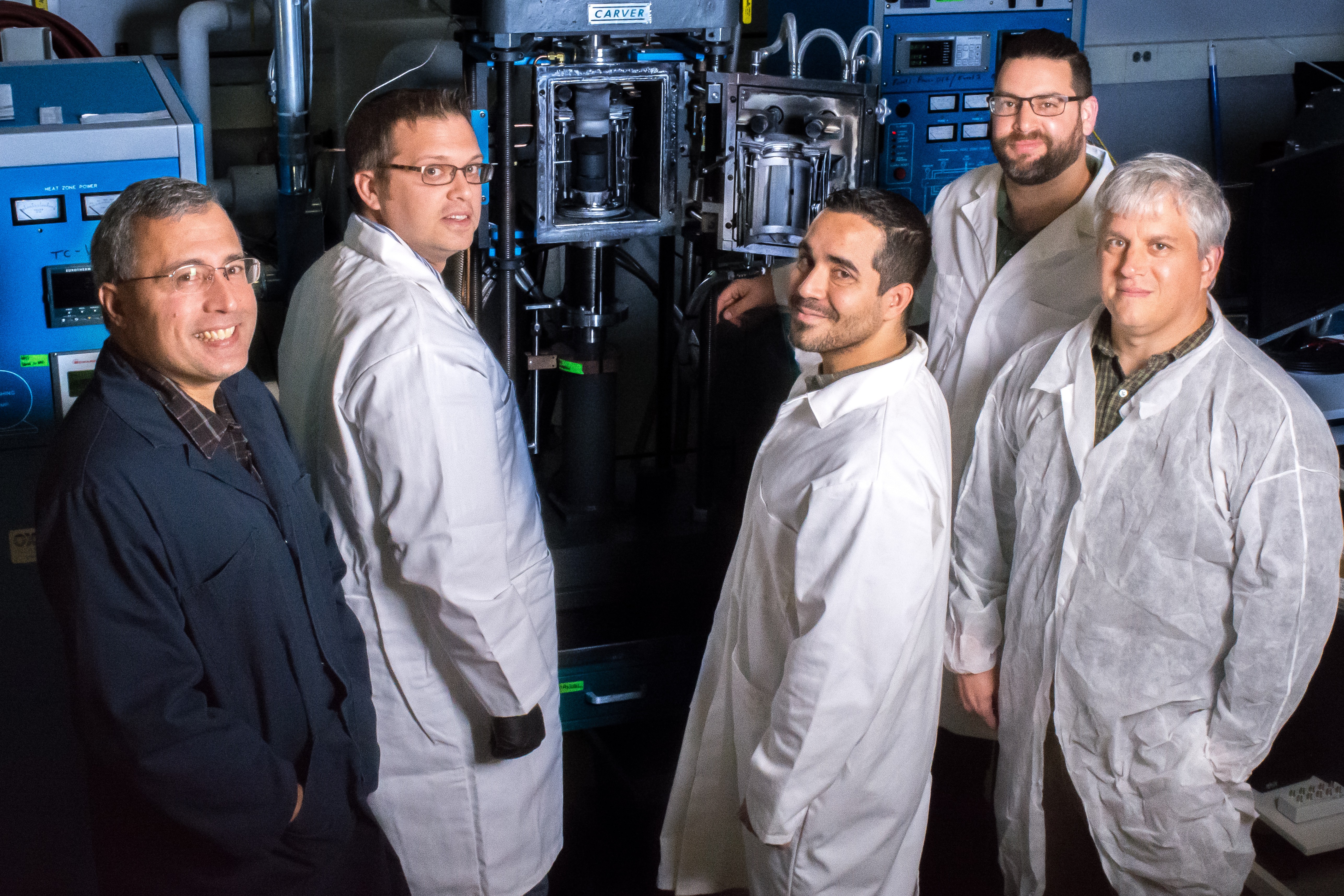

Vargas-Gonzalez's research team -- Dr. Jerry LaSalvia, Dr. James Campbell, Dr. Kristopher Behler, Dr. Clayton Weiss and Eugene Shanholtz -- are developing solutions for the synthesis of high purity B6O powders and the processing science for densification of the powders into dense ceramics.

"These efforts have yielded a new approach for synthesis of B6O, leading to an invention disclosure, and processing routes to enable theoretically-dense B6O coupons," he said. "These successes have generated high interest from Army stakeholders."

Both the Army and DOD Manufacturing Technology programs for Advanced Body Armor --Dr. Shawn Walsh -- and from PEO Soldier -- Dr. James Zheng -- made key investments and commitments to drive industry exploration of B6O synthesis and processing, he said.

"ARL is leveraging the ManTech- and PEO Soldier-funded efforts to further augment internal S&T, and to facilitate industrial collaboration for technology transition," Vargas-Gonzalez said.

Open Campus is a collaborative endeavor, with the goal of building a science and technology ecosystem that will encourage groundbreaking advances in basic and applied research areas of relevance to the Army.

"ARL has had fruitful partnerships with Ceramatec, Inc., and its parent company, CoorsTek, Inc., on several previous joint S&T efforts," he said. "Ceramatec expressed an interest in collaboration with ARL. The goal of this meeting was to generate a path forward for transition of ARL-led boron suboxide synthesis to a larger scale with an industry partner.

"Ceramatec has had a long history of successful transition from R&D to commercial, and brings a wealth of knowledge, expertise, and capability that will be crucial to developing a successful transition of our internal efforts to something that could potentially lead to the breakthroughs sought for dismounted Soldier protection."

The company invited Army researchers to its facilities in Salt Lake City to develop the strategy and path forward.

-----

The U.S. Army Research Laboratory is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command

Related Links:

Weapons and Materials Research Directorate

Social Sharing