NATICK, Mass. (May 24, 2016) -- When designing food processing and packaging for a future mission to Mars, researchers at the U.S. Army Natick Soldier Research, Development and Engineering Center, or NSRDEC, recognize the gravity of their task.

To best nourish Mars astronauts and maintain a quality of life, devising the right food packaging, combined with compatible and effective food processing techniques, is just as important as the food that's in it.

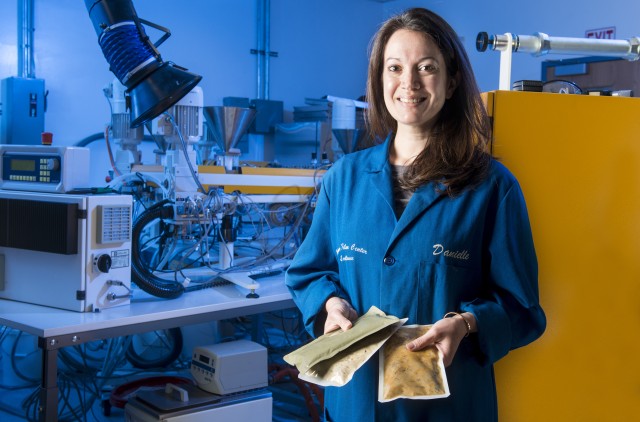

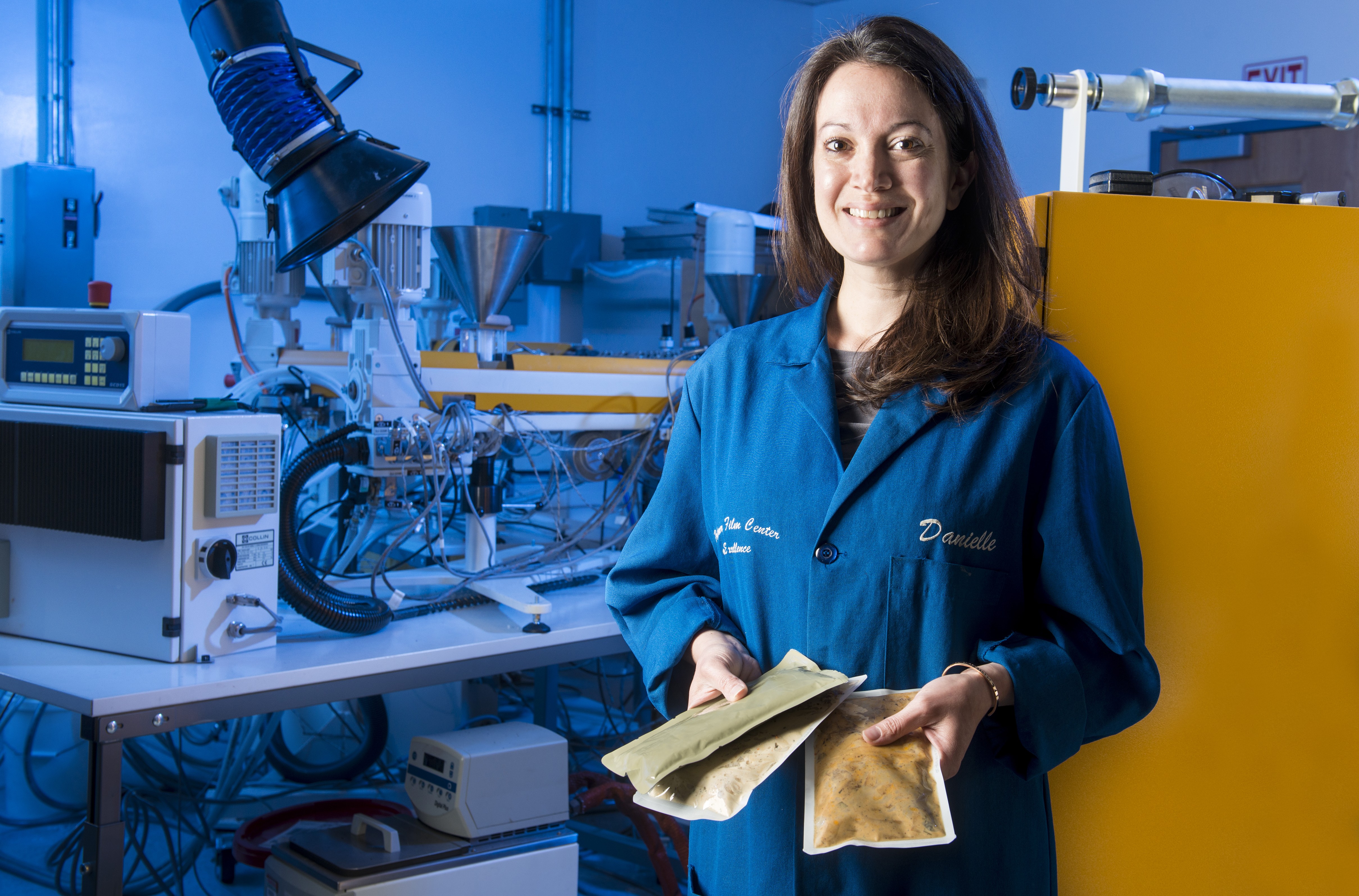

Danielle Froio, a materials engineer in NSRDEC's Combat Feeding Directorate, or CFD, is investigating the effects of various processing techniques and packaging materials on vitamin stability and shelf life. Froio's work on packaging is part of a larger CFD project with NASA that also involves Ann Barrett's work investigating matrix effects on vitamin stability and Michelle Richardson's work perfecting a breakfast meal replacement bar.

"Sometimes people assume that you can just put food in a package, but a lot has to go into designing a package for a specific food item," said Froio. "If you want to keep the moisture out, you need to use different materials than if you want to keep the oxygen out. It's important to design a package that meets the specific needs of a particular food item."

NASA reached out directly to CFD researchers for their expertise.

"We've had relationships with NASA over the years, so it is a really good fit because both the military and NASA have the same need for extended shelf life and even more so now with NASA trying to plan for a five-year shelf life for the Mars mission," said Froio. "They are prepositioning the food on Mars so it will be there before the astronauts get there -- that's why we need the five-year shelf life. The food will be their initial food source."

Froio is working on packaging and processing for a main entrée. One type of entrée is investigated at a time to better enable the selection of the most effective processing and packaging.

"I'm working on a retort food item, creamy Cajun chicken, which is very similar to an entrée that you would find in an MRE (Meal, Ready-to-Eat)," said Froio. "Part of this effort is looking at a high-water-activity food item, rather than the low-water-activity items that Michelle and Ann are investigating."

CFD is investigating packaging structures from previous MRE studies as well as commercially available pouches. The packaging will then be combined with different processing methods.

"With the MRE we use a retort process that is essentially like a pressure cooker," said Froio. "It sterilizes the food using a high temperature so that you can keep it on the shelf for up to three years and it is still safe to consume. For this project, we were looking at comparing the retort process, which can be thermally degrading to food, to some of these other novel-type processes that are not as thermally aggressive, like radiation, microwave-assisted thermal sterilization, or MATS, and also pressure-assisted thermal sterilization. Each of these processes reduces the integrated time-temperature exposure of the foods, which may help reduce vitamin loss. The three different processing techniques are being used with three different packaging materials to see what the effects of these processing methods are on the packaging alone."

CFD is investigating which packaging would survive which processes and then will determine what will be the best candidate to use in a three- or five-year shelf-life study, which will show which processing methods and/or packaging structures result in the most nutritious and highest quality food. CFD also did some testing to see if processing has any effect on the pouch seal, as well as a burst test to see how much pressure will cause the pouch to burst.

"We measured the mechanical properties of the different types of packaging and how strong they are both before and after processing," said Froio. "Another important property is oxygen and water vapor barrier performance, because that is an essential component to extending product shelf life."

It's scientifically challenging to come up with the right type of packaging since both the military and NASA demand a degree of uniformity.

"The military and NASA don't want to have 12 different pouches," said Froio. "They want to have one pouch that fits the bill for every different type of food item that they have. For these retort items, we have quad-laminate structures that have foil and three other layers of material. And for snack items we use a tri-laminate. All foods have to be able to be served in these two types of pouches."

For Froio, it's exciting to be working on a project that could impact a future Mars mission.

"Morale is tied very tightly to food," said Froio. "If you have a good meal that's tasty, then you will probably be in a lot better mood than when you have something that's cold and not tasting so well. For NASA astronauts, when they first get to Mars, this will be their primary food source until they are able to establish alternative food sources."

It's also rewarding to know that her work helps both warfighters and astronauts alike.

"Our work benefits both the military and NASA," said Froio. "Some of the pouches were developed for military applications, and now we are looking at them for NASA applications. And the work we do for NASA could also advance the processing and packaging technologies used for the military. They really do leverage each other very nicely."

--------------

The U.S. Army Natick Soldier Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Links:

U.S. Army Natick Soldier Research, Development and Engineering Center

Army.mil: Science and Technology News

Social Sharing