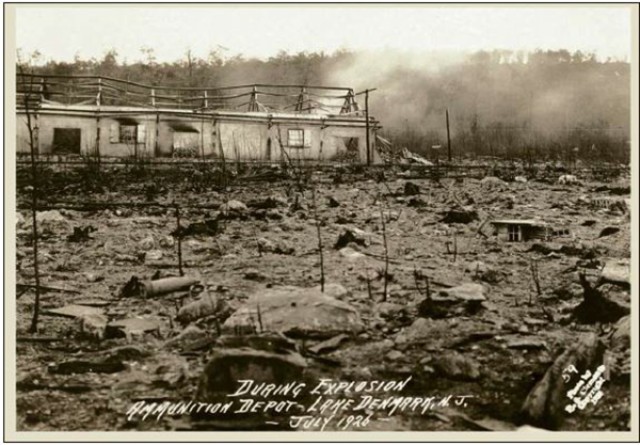

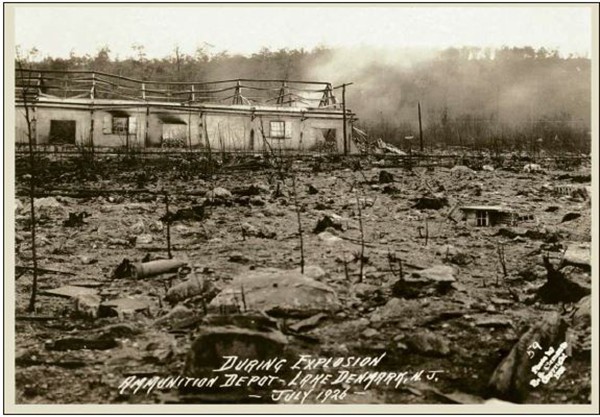

PICATINNY ARSENAL, N.J. -- On the morning of July 11, 1991, a defective heater in an M992 ammunition carrier loaded with 155mm artillery shells caught on fire in the North Compound of Camp Doha in Kuwait.

The burning M992 vehicle later exploded, showering nearby combat-loaded vehicles and ammunition stocks with artillery bomblets. That triggered an hours-long series of explosions and fires that devastated vehicles and equipment in the North Compound and scattered unexploded ordnance and debris over much of the camp.

Forty-nine Soldiers were wounded. Fires and explosions damaged or destroyed 102 vehicles. More than two-dozen buildings suffered damage. An estimated $15 million worth of ammunition was rendered useless.

SHIFTING EMPHASIS

During this period at Picatinny Arsenal, Ernest Baker was working on insensitive munitions (IM), which are intended to be less prone to violent reaction when subjected to impact from bullets and fragments, heat from fire, and shock from nearby explosions.

However, when Baker was hired at the Armament, Research, Development and Engineering Center (ARDEC), the area of insensitive munitions had less emphasis. In the mid-90s, his team was having difficulty fielding some new types of traditional munitions.

"They were dangerous in a fire or if we were attacked," Baker recalled. "After Camp Doha in Kuwait blew up in 1991, I believed I could help develop technology or be involved in the development of technology that could solve those problems and mitigate the violent response."

Baker is now in a position to play an important role in producing safer munitions. Recently, Baker was designated as one of only 500 Senior Research Scientists.

"This honor gives me an opportunity to emphasize areas that I feel are important, such as making safer insensitive munitions and increasing Soldier survivability," Baker said.

"It's also an opportunity to mentor young engineers and scientists by helping them identify areas that they can work on so they feel important and are challenged on a daily basis."

EASING THE WARFIGHTER'S JOB

In his new role at the ARDEC, Baker will conduct research and development of insensitive munitions technology and its application to Department of Defense (DoD) systems.

He will also provide technical and coordination consultative assistance for IM, be a leader and role model for the ARDEC engineers interested in pursuing a technical career development path, and guide the ARDEC organizations in the improvement of IM capabilities.

Insensitive munitions are not only safer and more stable than traditional munitions, but they ease the warfighter's job when it comes to transporting, storing and loading ammunition. With less sensitivity, the Army can store more shells in a magazine and store more munitions in one building closer to Soldiers, which reduces the logistics burden.

THE PATH TO IM RESEARCH

Baker's interest and advancement in insensitive munitions seems in retrospect to have taken a natural path.

He grew up in Pullman, Wash., and earned his master's degree in 1985 from Washington State University, where his father was a professor of electrical engineering.

Never having been east of the Mississippi River, he decided to send out a bunch of resumes to potential employers in the Eastern United States.

He landed an interview with Pai Lu, who has since retired from Picatinny Arsenal. Lu hired Baker and piqued his curiosity regarding insensitive munitions and explosive behavior.

"Picatinny looked incredibly interesting and I didn't realize that my whole career was leading me towards high explosives," he recalled. "I came out here to New Jersey and thought I'd only be here for a few years and now it is 25 years later."

A former colleague, Barry Fishburn, gave Baker a piece of advice that has stuck with him ever since.

"One of the most valuable lessons I have learned over the years is to never make big decisions off the cuff,. Sleep on them first before you decide anything," Baker said.

THE VALUE OF COLLEAGUES

Others who have influenced Baker during his career included Jim Pearson, for his expert knowledge of shape charge technology; Joe Orosz, his former supervisor, for his broader application to warheads technology; Leonard Stiel, for his deep understanding of explosion chemistry, and his longtime colleague Brian Fuchs, for his great expertise in munitions experimentation.

But his most helpful advice came from his parents. "They told me to leave things a little bit better than the way I found them and that's the way I've tried to live my life," he said.

Among Baker's career technical milestones is developing one of the first ways to predict the behavior of shaped-charge warheads through computer modeling.

From that important development, he became interested in computer modeling the behavior and chemistry of explosives, which he called "a huge step forward." He considers his most significant milestone to be extending the knowledge of how explosives containing aluminum behave and detonate.

CHALLENGES OF THE NEW JOB

In this new job, Bakers sees two major challenges related to technology development of insensitive munitions: coordination of the broad range of different technologies and developers, and transitioning new technologies into standard practice.

"IM is a system-level issue, and therefore involves technology development across a broad range of munitions technology areas: explosives, propulsion, pyrotechnics, warheads and packaging/logistics," Baker explained.

"Bringing all these technologies and the technology developers together can be challenging."

Baker noted that incorporating insensitive munitions onto fielded munitions is a complex undertaking. Many factors affect the process, including lifecycle aspects, cost, production capability, impact of the new technology and scheduling issues.

MULTILEVEL COORDINATION

At the local level, Baker coordinates the ARDEC research and development of insensitive munitions technology and continually updates the ARDEC IM "roadmap" in conjunction with Program Executive Office Ammunition.

"We have formed the ARDEC/PEO Ammunition IM integrated process team (IPT) to foster both communications across technology areas, as well as to help bridge the divide between technology development and munitions application," Baker said.

"At the U.S. Army level, we support the U.S. Army IM Board through membership, participation that includes science and technology briefs and IM engineering support to various Program Managers," Baker said.

"At the Department of Defense level, we are largely involved with the Joint IM Technology Program and the Joint Service IM Technology Panel.

"My intent is to further build our DoD level coordination and cooperation through increased participation with the DoD IM IPT.

"My goal to help build the DoD IM IPT into an effective forum for sharing our evolving technologies to help assure the fielding of systems with the best IM features."

While Baker recognizes the need to advance munitions technology to avoid catastrophes such as those at Camp Doha, nurturing the development of the ARDEC workforce is also a critical management responsibility.

To young engineers and scientists, Baker says: "Find something that you're extremely interested in.

"When the work is important and you are passionate about it, that's when you will make the greatest impact for ARDEC, the U.S. Army and the Soldier."

Allyson DiPaolo is a strategic communications marketing specialist at ARDEC. Ed Lopez is editor of The Picatinny Voice.

-----

The U.S. Army Armament Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing