ABERDEEN PROVING GROUND, Md. (March 8, 2016) -- At the height of World War II, Army researchers set up the world's first large-scale, fully instrumented ballistic range capable of producing data on the aerodynamic characteristics of projectiles in free flight.

Since 1943, the Aerodynamics Experimental Facility in APG's Building 328 has provided researchers with the ability to study what happens to objects in free flight.

Members of the American Society of Mechanical Engineers, or ASME, recognized these contributions when they designated the facility a National Historic Mechanical Engineering Landmark in 1982.

Historic mechanical engineering landmarks are existing artifacts or systems representing a "significant mechanical engineering technology," according to the organization's website (see link in Related Links). "They generally are the oldest extant, last surviving examples typical of a period, or they are machines with some unusual distinction."

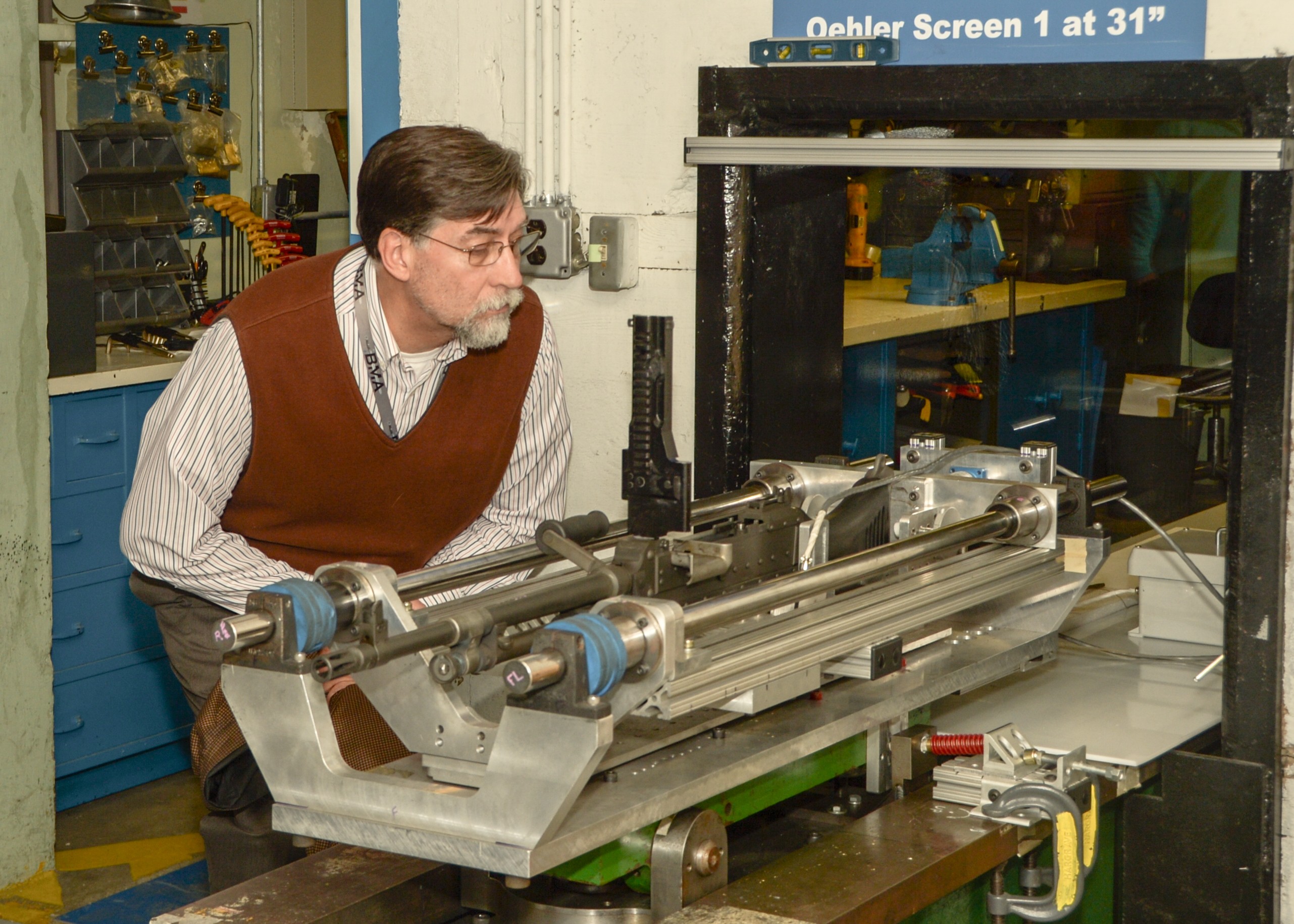

During a Feb. 25, 2016, tour of the laboratory, ASME Baltimore members listened to Army researchers explain how the facility is still in operation today.

"Primarily we do the underpinning research that goes through the development cycle and through fielding of any sort of system for the Army or ground forces in general," T. Gordon Brown, Guidance Technologies Branch, U.S. Army Research Laboratory, told the nine visiting engineers during the tour.

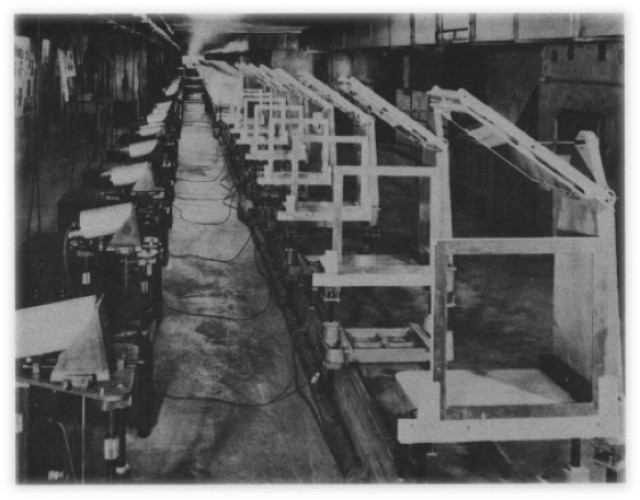

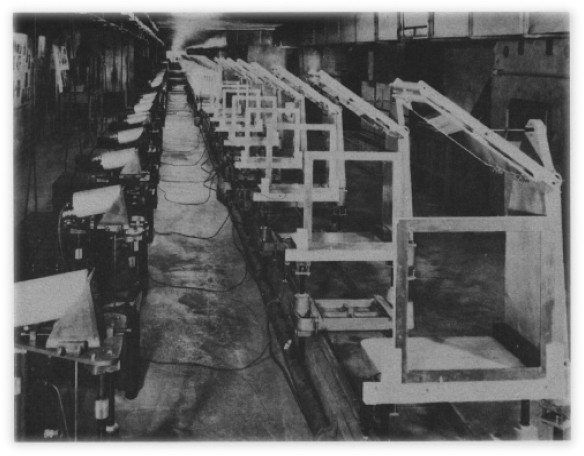

The Aerodynamics Experimental Facility consists of a 100-meter range with a firing room, a blast chamber and a series of photographic stands that accurately record the flight characteristics of projectiles fired down-range.

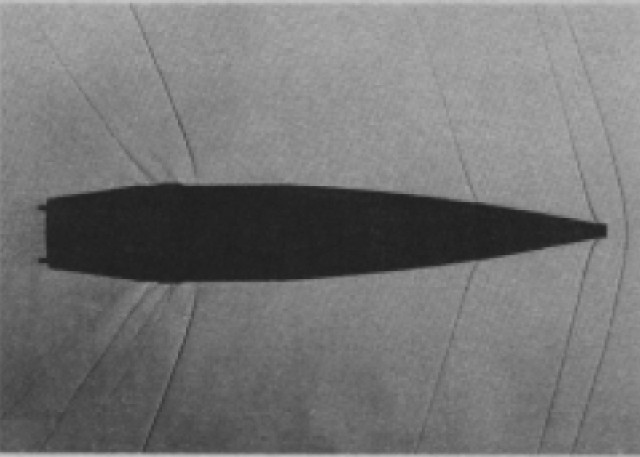

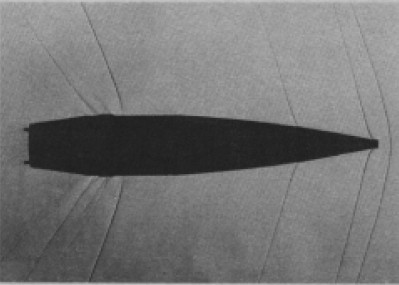

The key to analysis is something call spark shadowgraph photography. A spark is a high-intensity, short duration light source; it is used to capture the shadow of a fast moving object on film without it becoming blurry.

"Spark shadowgraph photography is used to capture the flight trajectory of a projectile using the shadowgraph images from which the six degree-of-freedom motion can be measured allowing for projectile aerodynamic characterization," Army researcher Sidra Silton told the group. "This is one of two spark photography facilities operated by the Flight Science Branch at ARL."

Silton said the facilities are still considered the "gold-standard" for aeroballistic experimentation, particularly when dynamic flight stability is important.

"This range is suitable for projectiles of the smallest caliber, such as 5.56-mm ammunition, to projectiles of medium caliber, such as 40-mm grenades," Silton said. "The spark range has 39 orthogonal plane shadowgraph stations arranged in five groups. The range uses infrared sensors and a preset time delay unit to trigger high-voltage spark sources, causing a spark shadowgraph image of the projectile and surrounding flow field to be captured on film."

The spark sources are connected to a computer that records when each source triggers.

"Each station is surveyed into a system that's simultaneously imaged onto the film," she said. "Each piece of negative image film is digitally processed to produce the measured spatial coordinates such as range, deflection, altitude, and angular orientation such as pitch, yaw, and, if a spin pin is used, roll angle, relative to an earth-fixed range coordinate system, all as a function of the spark time."

ASME members asked many questions during the visit.

"Great facility and great tour," said John Lambert. "I am a former employee at Aberdeen Test Center and worked with a few ARL folks preparing for tests, although I rarely ever got out to the ranges. I moved on -- down at Edgewood now with PEO ACWA [Program Executive Office - Assembled Chemical Weapons Alternatives]."

Lambert said he was not surprised to see the facility in use after all these years.

"[I'm] amazed that they were able to develop and use that technology back in the day," he said. "It will be bittersweet when ARL eventually upgrades…losing the historical relevance."

David C. Zupko, an ASME life member, said he spent most of his career at the Aberdeen Test Center.

"It was great to see such an important range still active and providing economical data for ballistic testing," he said. "I thoroughly enjoyed the tour. All of the briefing team did an excellent job."

ASME member Stacey Sullivan was also impressed by the visit.

"What a facility and history that all Americans should be very thankful for," she said. "It is amazing work and I found it very interesting."

-----

The U.S. Army Research Laboratory is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Documents:

<b>PDF:</b> Historic Ballistic Facility [PDF]

Related Links:

Army.mil: Science and Technology News

Social Sharing