TOBYHANNA ARMY DEPOT, Pa. - A technologically-advanced process will save time and improve the quality of cable harnesses produced at Tobyhanna.

Personnel in the Tactical Communications Facilities Branch will now use peg boards and a computer program to fabricate cable harnesses. This process, which was once a time-consuming task that consisted of nailing in and removing nails from a board, will allow technicians more versatility, said Vic Narsavage, electronics mechanic leader in the branch. The branch, which is part of the Systems Integration and Support Directorate's Electronic Services Division, boasts 107 employees on three shifts.

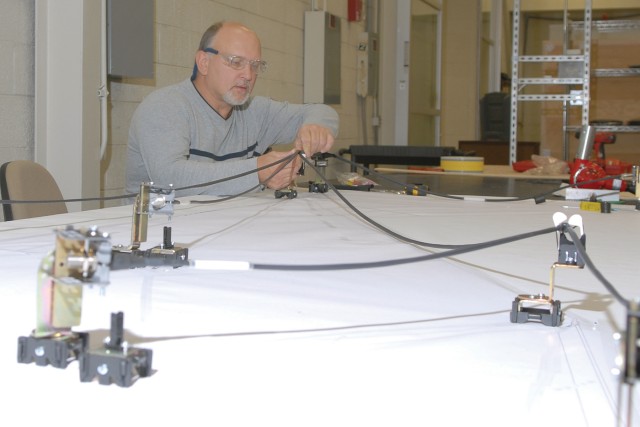

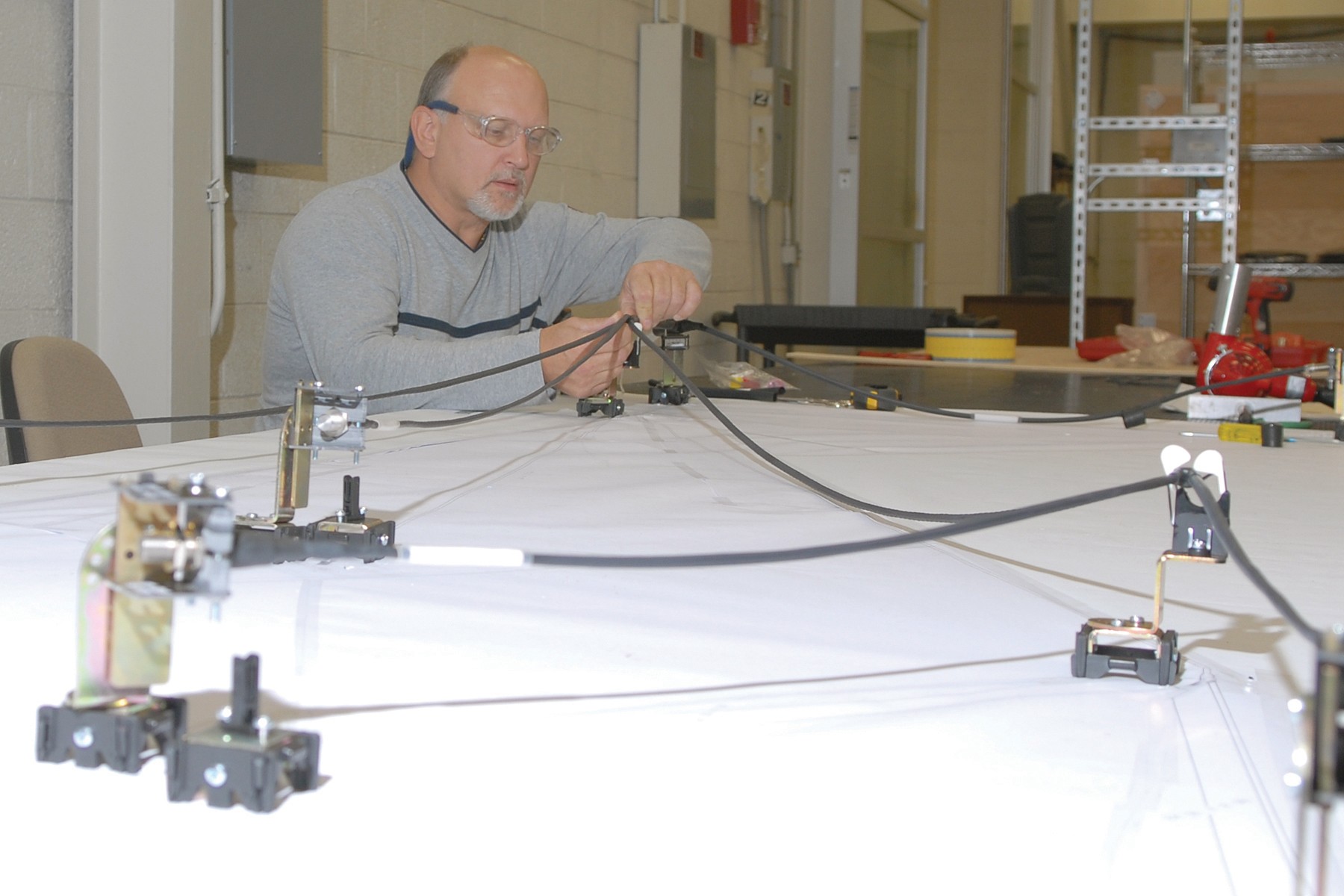

The new procedure, implemented this month, is similar to the old one because it allows technicians to follow a largescale drawing of the harness while fabricating cables.

The drawings are placed on tables that are 4 feet by 8 feet. "These tables can also be combined to accommodate fabrication of larger cables," explained Narsavage.

After the drawing is placed on a pegboard, which is located atop the table, the technician inserts pegs following the designated placement on the drawing. Connectors, which secure the pegs in place, are locked into the board. Once the cable is fabricated according to the drawing, it is hooked-up to a main connector, which runs concurrently with a computer program.

"The set-up is similar to an ESD [electrostatic discharge] station, being that a wire and wrist strap are attached to the individual," explained Cal Morgan, division chief. "The wire is then attached to the tester."

The technician will use the computer program to direct, or thread, each wire. Once the technician locates the correct spot, they snap the wire into place.

The tester checks resistors, diodes and capacitors on the harness, and is designed to find wiring errors, as well as bad solder joints.

Blinking light emitting diodes are designated as test points and allow the technician to locate opens, shorts and miswiring. The computer also produces specific audible tone sounds for good and bad connections.

"The new method will not only save time while fabricating a cable but will save time during set-up and teardown, and while testing," explained Narsavage. "The harness remains on the board from start, until it's a finished product." The old method required at least 10 minutes for teardown.

Other benefits include the newly integrated tables, which are built to accommodate ergonomics. The table can be lifted or tilted, similar to drafting tables, depending on the individual's preference, said Morgan.

"The tables can be cleared off and a new cable is set up in about five minutes," he explained. Because of the new process drawings will undergo minimum wear-and-tear, which will allow technicians to save the drawings and file them for future use.

Morgan plans to equip the branch with eight tables. Each table will also be provided with a designated computer for cable testing. He says the number of tables will accommodate incoming workload.

Tobyhanna Army Depot is the largest full-service Command, Control, Communications, Computers, Intelligence, Surveillance, and Reconnaissance (C4ISR) maintenance and logistics support facility in the Department of Defense. Employees repair, overhaul and fabricate electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network.

Tobyhanna's missions support all branches of the Armed Forces. The depot is the Army Center of Industrial and Technical Excellence for Communications-Electronics, Avionics, and Missile Guidance and Control Systems and the Air Force Technology Repair Center for ground communications and electronics.

About 5,700 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army CECOM Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the command's mission is to research, develop, acquire, field and sustain communications, command, control, computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing