TOBYHANNA ARMY DEPOT, Pa. -- Most people hear the word "forensics" and think of dusting for fingerprints, conducting lab tests and the general pathology used to solve crimes. But a depot engineer has taken a closer look at this science and transformed it through his studies to bolster Tobyhanna's innovative and cutting-edge capabilities.

"I get to take some of the forensic applications you see in TV shows and movies and apply them to various processes at the depot," said Leonard Zito, quality engineer in the Continuous Process Improvement's Quality Assurance Division.

Zito is set to receive his Doctorate of Forensic Engineering from Columbia University next month after completing 60 credits of coursework and a thesis exploring the formulas that map corrosive patterns in Air Force assets. For more than 10 years he has been intensely involved with analyzing recurring problems including mechanical, structural, electrical, material and testing failures at Tobyhanna and in the field, and has tied his forensic experience to these processes.

"I've been doing this here for years now as the quality engineer, but I decided to turn it up a notch and pursue forensic science to expand my expertise," said Zito.

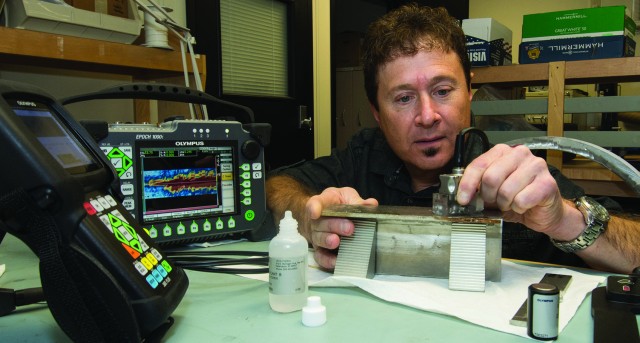

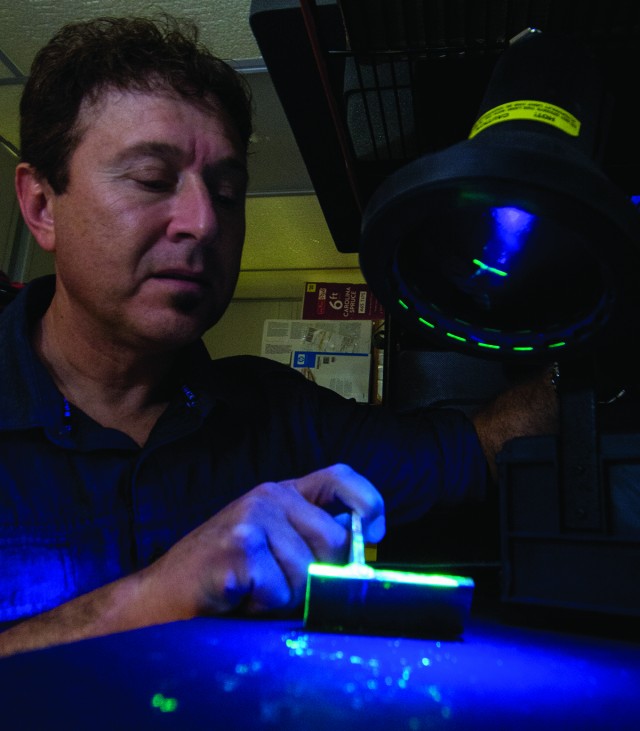

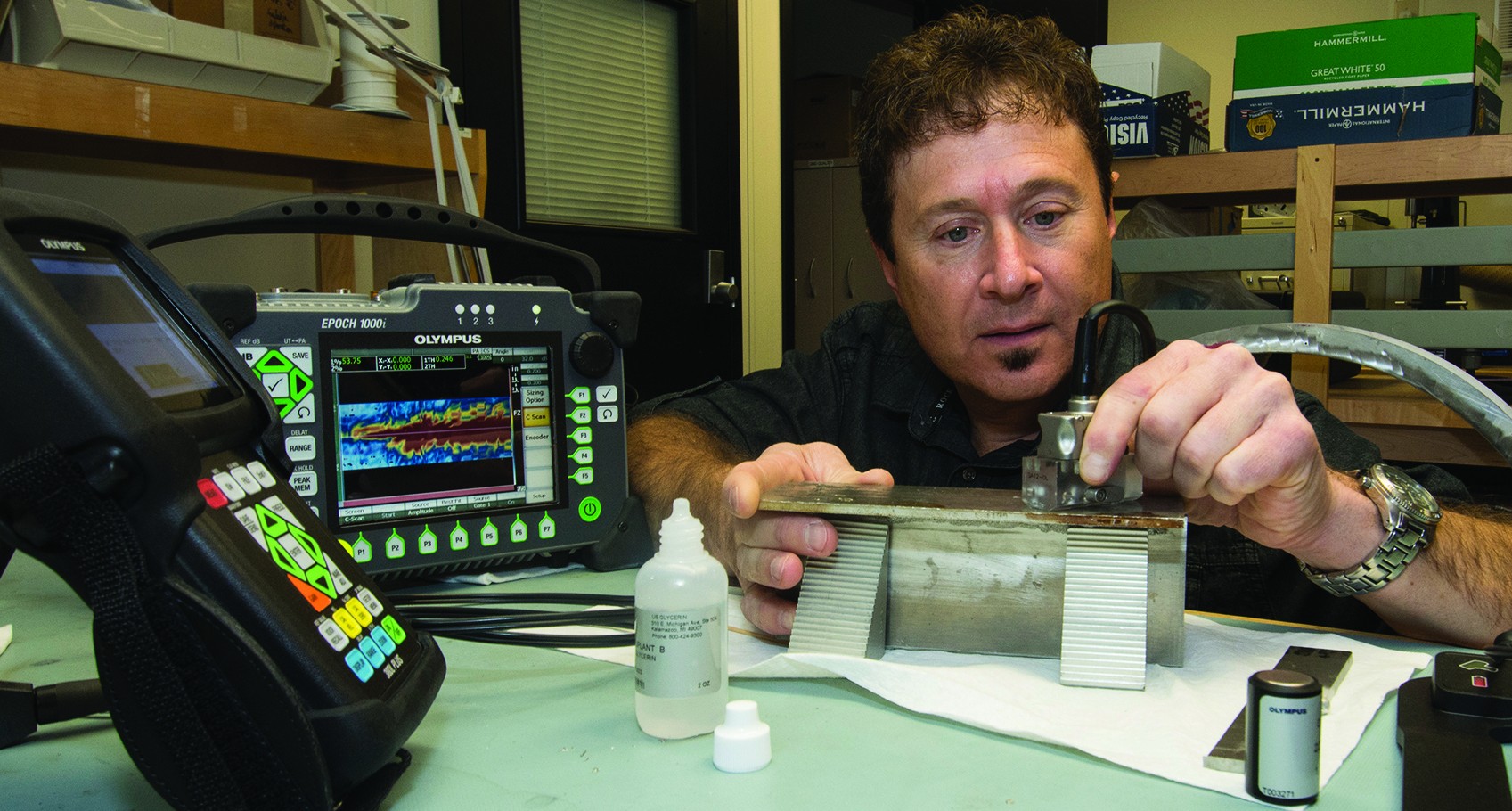

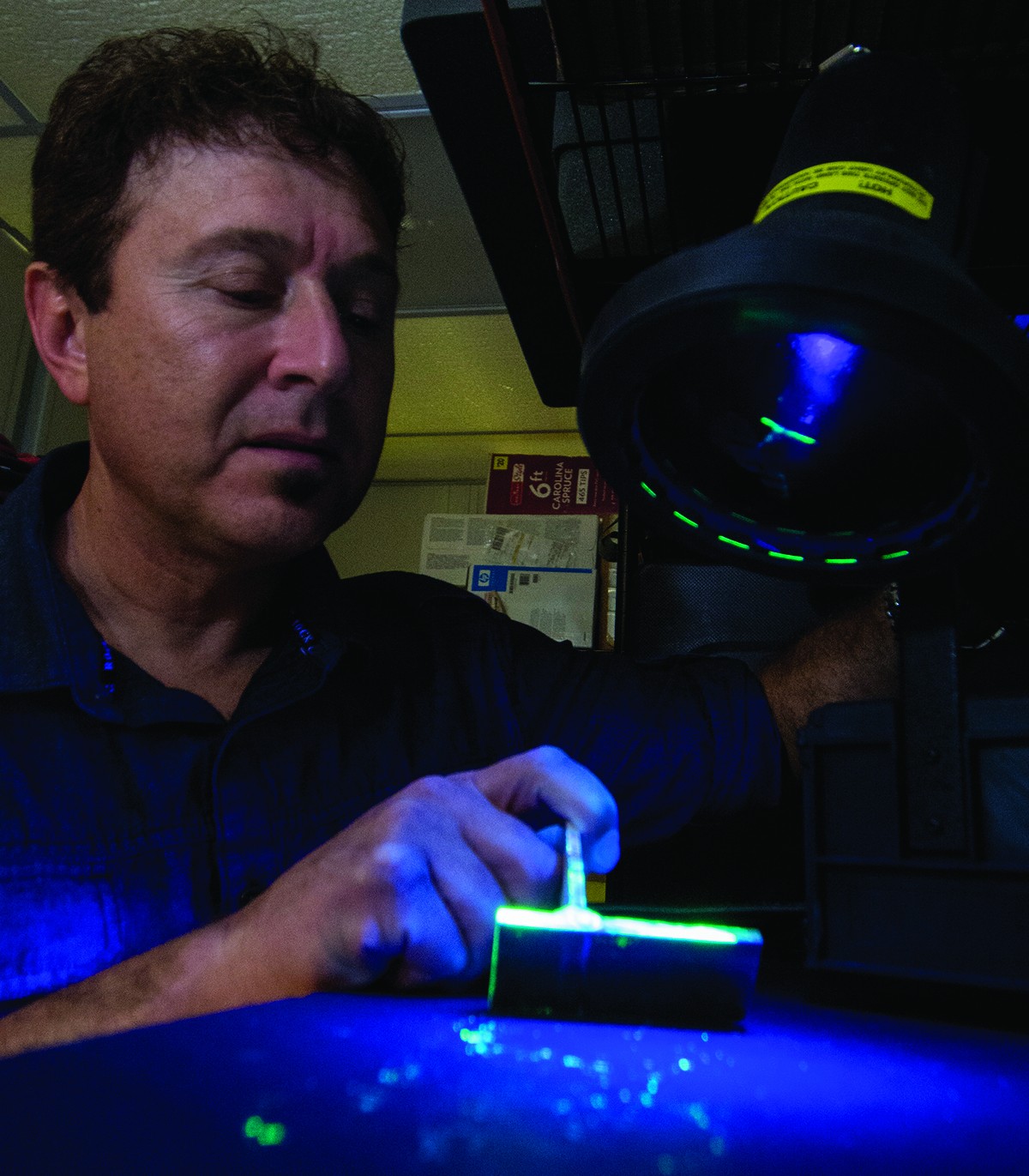

One example of how Zito uses a forensic approach in a traditional testing environment can be seen when testing radar systems in an Air Defense Test Facility, more commonly known as a Radome. Using ultrasonic, phase arrays and CT scans, Zito can identify an inconsistency in the hydrophobic coating on the inner-walls of the enclosed, weatherproof Radome which may lead to signal interruptions during testing. Without recognizing a structural fault like this, any signal errors would instead be linked to the radar system, potentially causing unnecessary rework.

"That's the big thing -- taking a fine-toothed look at the testing environment itself instead of just the system or equipment," said Zito. "Avoiding rework will save the depot time and money, and these levels of analysis will expand Tobyhanna's capabilities going forward."

Brad Jones, chief of the depot's Continuous Process Improvement Directorate, holds Zito in the highest regard and recognizes his daily effort to enhance the quality of Tobyhanna's work.

"Lenny possesses a genuine passion for quality assurance. He is always striving to learn more down to the deepest levels of the profession," he said.

Zito has seen his fair share of interesting things throughout his forensic studies, though he can't talk about every experience.

"Some things are classified, but my work in Radomes and with structural defects has been one of the most intriguing things I've done," he said. "I've been lucky enough to see and work on a wide range of really cool things in this field."

Of course, Zito's discipline comes with a steep learning curve. Most places he travels to aren't armed with forensic test equipment and haven't yet subscribed to forensic testing as a priority. However, organizations like the Federal Aviation Administration and many legal settings have adopted forensic science to reconstruct environments to recreate some sort of failure.

"That's what I've been doing, just on a macro level," said Zito. "We are adding new equipment to our quality lab and are developing new procedures for testing all the time."

Jones added that Zito's expertise opens new doors for the depot. "Working with Lenny is humbling because he is such an expert in his profession and he is always willing to help others," said Jones. "He has been key in bringing new workloads to Tobyhanna because of how he performs in the field, the reputation he carries with him and his determination to come up with better processes to enhance the quality function here."

Zito's advice for engineers looking to get into forensic science is simple: do it.

"If it's your passion, go for it," he said. "Working in this field has taken me all over the world and has allowed me to directly impact the work being done at the depot. It has been a perfect fit for me."

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for C4ISR systems across the Department of Defense. Tobyhanna's Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C4ISR provider of choice for all branches of the Armed Forces and industry partners.

Tobyhanna's unparalleled capabilities include full-spectrum logistics support for sustainment, overhaul and repair, fabrication and manufacturing, engineering design and development, systems integration, post production software support, technology insertion, modification, foreign military sales and global field support to our Joint Warfighters.

About 3,100 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania. Tobyhanna Army Depot is part of the U.S. Army Communications-Electronics Command. Headquartered at Aberdeen Proving Ground, Maryland, the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing