WATERVLIET ARSENAL, N.Y. Aca,!aEURc U.S. Army Watervliet Arsenal, the oldest, continuously active arsenal in the country, closed out 2008 unlike many other manufacturing businesses in the nation - its orders and direct labor requirements grew.

As the nation's manufacturing activity fell last year to its lowest point in 28 years, the Arsenal's production requirements grew by more than 25 percent last year, said Col. Scott N. Fletcher, Arsenal commander.

"Although most people may associate the Arsenal as a cannon factory, our growth came mostly from non-cannon manufacturing," said Fletcher.

The Arsenal experienced a steady flow of cannon manufacturing requirements last year, but true growth came from research and development programs that funded other production requirements such as the Non-Line-of-Site Mortar, Non-Line-of-Site Cannon, Abrams Tank fan kits, and the prototype development of an electromagnetic rail gun. The Arsenal also experienced significant order growth for 81 mm and 120 mm mortar systems, mortar base plates, and Gunner Protection Kits for HMMWV's.

Being an Army installation does not protect the Arsenal from having to operate with a profit and loss structure similar to private manufacturing businesses. "We had to expand our product line to meet the immediate needs of the Army, as well as to maintain a competitive edge in the manufacturing industry," said Fletcher.

Not only did the increased production have a positive effect within the Arsenal, but also the local community gained by the Arsenal's success.

According to John Hockenbury, Arsenal Operations & Production director, to sustain the Arsenal production growth, while maintaining an on-time delivery performance of greater than 97 percent, the Arsenal had to create new jobs.

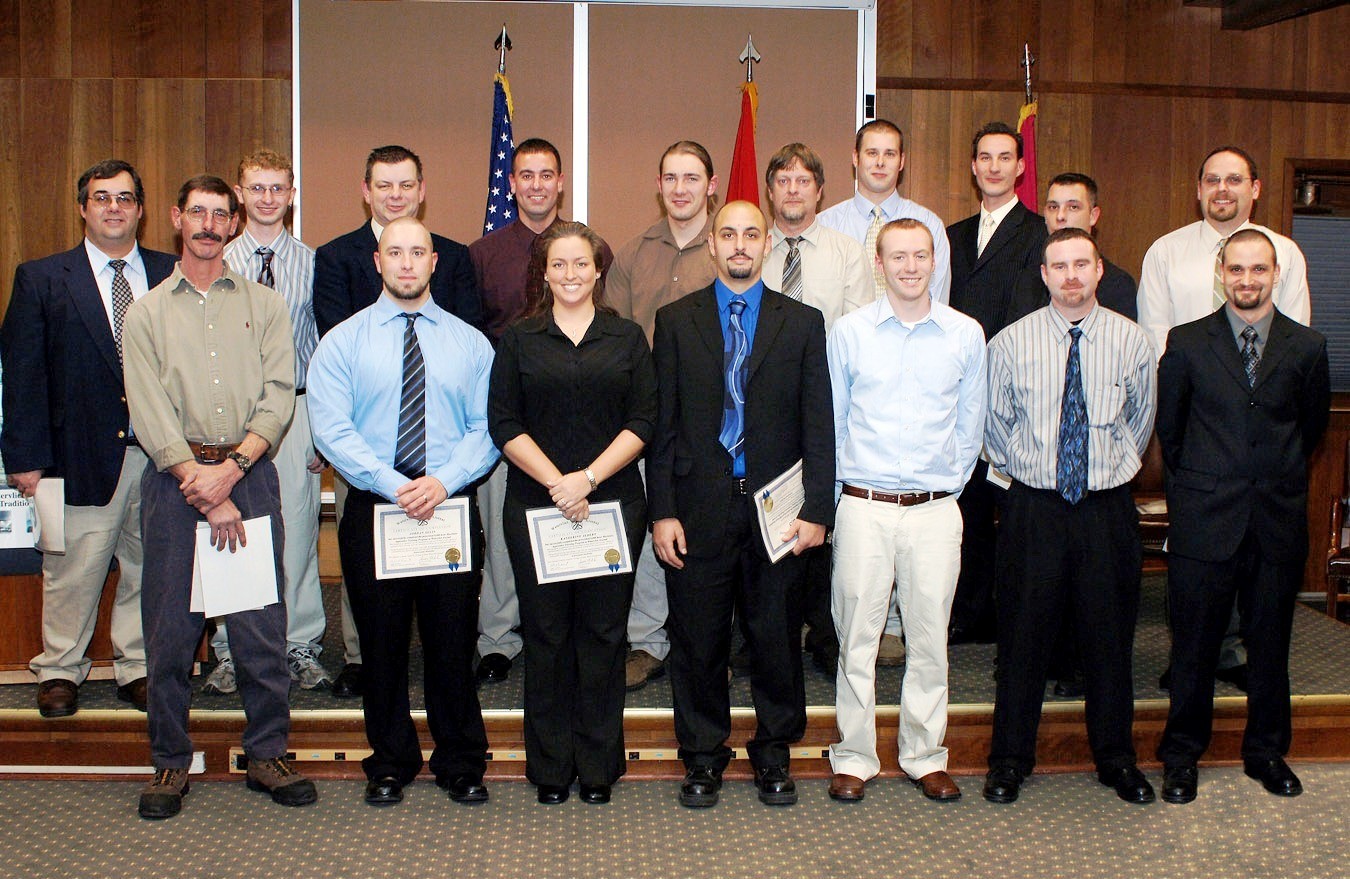

"In fiscal year 2008, the Operations Directorate hired 57 new employees," said Hockenbury.

Hockenbury said that many of the new hires were well-experienced having learned their trade at such companies as Albany International Corp., Nova Bus, Applied Robotics Inc., NSK Ltd., and Eagle Bridge Machine and Tool Inc. He also said he was quite pleased to hire 10 new apprentices that were part of the 57 new hires.

According to Hockenbury, the Arsenal Apprentice Program is a four-year program that requires 8,000 hours of hands-on training in the production bays, as well as classroom study at Hudson Valley Community College.

"The apprentice program is essential to our success in that it provides journeymen machinists who will often stay at Arsenal for their entire careers. With an average workforce age of 47, these apprentices truly are the Arsenal's hope for the future," added Hockenbury.

Despite a great year of production, Fletcher said that he is not getting comfortable with production requirements that currently look good through 2010.

"In addition to aggressively seeking more defense work, we need to do a better job of promoting our machining and tooling capabilities to the public sector," said Fletcher. "By partnering with the private sector, we will be better able to weather any potential downturn in military orders."

Fletcher is adamant that with more than 600 machines, which about one-third are computer controlled, there is no part or machined product for civilian application that his 200 production workers cannot manufacture.

The Arsenal is located on 143 acres in the center of Watervliet, N.Y., and has more than two million square feet of floor space, more than half of which is for industrial operations. In the 1980s, $300 million was invested to upgrade buildings, processes and equipment making the Arsenal one of the most modern manufacturing facilities in the northeast. The Arsenal is also near major academic institutions such as Rensselaer Polytechnic Institute, the State University at Albany College of Nanoscale Science and Engineering and Union College. The Arsenal is ISO 9001 certified, a Lean Six Sigma continuous improvement organization, and is a Voluntary Protection Program participant that institutionalizes safety in the workforce.

Social Sharing