WATERVLIET ARSENAL, N.Y. (Oct. 30, 2015) -- Former Army Secretary John M. McHugh said earlier this year that the way ahead for the Army is to build weapon systems that can be incrementally upgraded to adapt to the realities of the day, but the Watervliet Arsenal isn't waiting for the future as it is already modifying current weapon systems for the realities of today.

The Arsenal announced today that it has received orders totaling nearly $1.3 million to provide the Army with a new, lightweight bore evacuator for the self-propelled howitzer system, the M109A7. The M109 series howitzer was originally fielded throughout the Army decades ago.

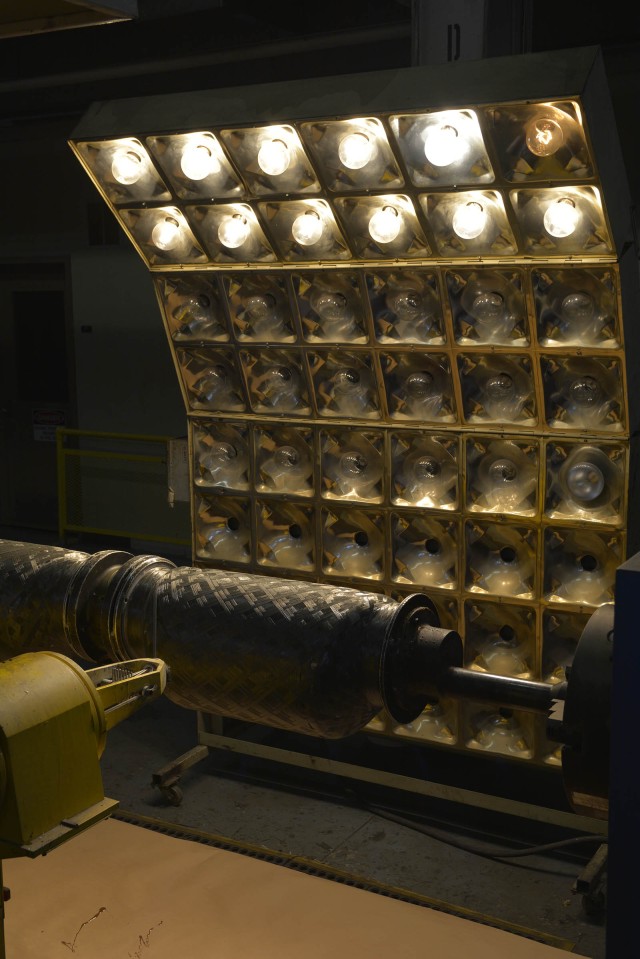

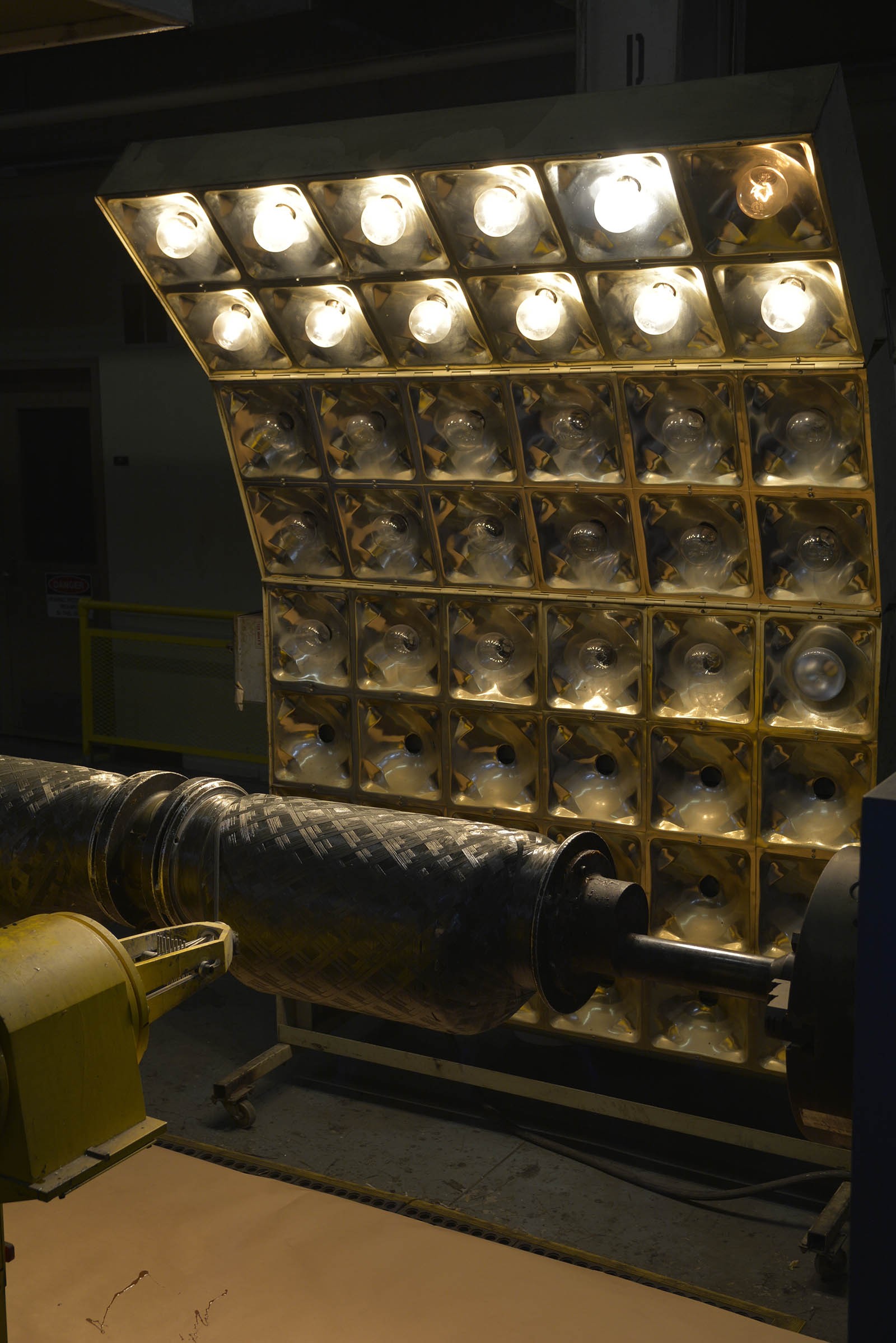

This new evacuator will reduce the weight of the current version, which is made from steel, from 203 pounds to about 110 pounds for the new fiberglass version. Making the gun system lighter is only secondary, however, to the effect of making a rather difficult maintenance job much easier for the artillerymen.

What is also great about going after "incremental" improvements, such as what McHugh suggested, is that the arsenal can field a new product that will provide dramatic improvements for the Soldier in a significantly reduced acquisition window.

"What we did was to take a decades-old manufacturing process that is being used on the 120mm tank cannon and modify that design for the self-propelled artillery system," said Joshua Root, a mechanical engineer with the Army's Benét Laboratories. "It took us (arsenal manufacturing and Benét Laboratories) a little more than two years to go from concept to prototype development."

Gregory Stone, the arsenal's supervisor for the metal processors, who are doing the manufacturing work, said that this is great work for his team in that the job exercises several critical skill sets, from welding to lathe machining to fiberglass winding.

Just last month, the arsenal reported that it has received orders totaling nearly $20 million to introduce a bore protection coating for the self-propelled howitzer cannon, the M284A2, that will extend the wear life of those tubes by up to 50 percent.

And so, it seems lately that the Army is investing a significant amount of resources at the Watervliet Arsenal to keep a decades-old howitzer system in good shape for the next fight. The M109 has had a number of major upgrades through the years and is now on the M109A7 version.

This effort, performing work that will incrementally upgrade current systems, may be just what McHugh meant when he recently spoke at the American Enterprise Institute.

"We understood that sometimes good enough is good enough and we recognized that the affordable way for us in the future was to build something in a fashion that incrementally, from generation to generation, you could add on and adapt to whatever the new realities of the day may be," McHugh said.

The current orders will only retrofit approximately 50 percent of the self-propelled fleet of howitzers. The Arsenal anticipates follow-on orders to equip all self-propelled howitzers with the lightweight bore evacuator.

The Arsenal will begin shipment of the new evacuator in December 2015 and will complete these orders by January 2017.

A bore evacuator is used on the gun barrels of the Abrams tank and the M109 howitzer to help reduce propellant gases and pressure from venting back into the vehicle's firing compartment.

The Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest, continuously active arsenal in the United States having begun operations during the War of 1812. It celebrated its 200th anniversary on July 14, 2013. It is a subordinate command to the TACOM Life Cycle Management Command at Warren, Mich., and the Army Materiel Command at Redstone Arsenal, Ala.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark had revenue in fiscal year 2015 that exceeded $135 million and provided an annual economic benefit to New York of nearly $100 million.

Benét Laboratories is a Department of the Army research, development and engineering facility located at the Watervliet Arsenal. It is a part of the Weapons & Software Engineering Center (WSEC), an organization under the Army's Armament Research, Development, and Engineering Center (ARDEC), part of RDECOM.

Related Links:

Story: AMC commander honors former Arsenal apprentice who rose to greatness

Watervliet Arsenal Slideshare Page

Watervliet Arsenal YouTube Page

Watervliet Arsenal Twitter Page

Social Sharing