As the Army moves to an enterprise resource planning (ERP) environment for sustainment systems, implementing industry best business practices is essential. One such practice is developing a standardized and integrated process to create, update, and syndicate bill of materials (BOM) data.

A BOM is a list of the parts or components that are required to build a product. In integrated ERP environments, such as the Logistics Modernization Program, Global Combat Support System-Army (GCSS-Army), and the Army Enterprise System Integration Program (AESIP), BOM data is enterprise-level master data designed to be used together and accounted for collectively and individually. An example is a tool kit that is built with a certain kind, brand, and number of tools at the enterprise level and then used to maintain a specific truck in the Army's fleet.

A centralized process for managing and integrating BOM data in the Army's ERP environment ensures integrity of the information and proper accountability down to the end-user level. The purpose of this article is to describe to GCSS-Army users the processes essential for BOM functionality and integrity.

CURRENT SHORTFALLS

Current sustainment information systems have created shortcomings in BOM data management. In the Property Book Unit Supply Enhanced (PBUSE), unit-level users can create entire component listings without appropriately validating BOM structures. These records often have inconsistencies when compared with current enterprise-level BOM structures and contain materials that were not cataloged.

Old BOM structures also are not synchronized with technical manuals because when the structures were created, there were no automated sources to create, update, or validate BOM component listings. In some cases, BOM structures are outdated because of ongoing equipment modifications that are not communicated to the systems or the end users. Because of these discrepancies and shortfalls, the BOM structures in PBUSE cannot be transferred to the Army's ERP systems.

VALIDATING DATA

In GCSS-Army, current BOM data is created and updated manually by researchers who sift through data sources and validate entries before uploading them into GCSS-Army. As GCSS-Army enters Wave 2, this manual validation process is unsustainable. The frequency of BOM changes will be compounded by the number of units in the fielding schedule and the amount of equipment units have to load in GCSS-Army.

The GCSS-Army Wave 2 fielding is significant to the central management of BOM structures because during the Wave 2 fielding GCSS-Army will replace PBUSE and the Standard Army Maintenance System-Enhanced.

AUTHORITATIVE DATA SOURCES

The Army will now operate a single, enterprise-level BOM structure in which all BOM data will be centrally managed and sent to trading partners [organizations that exchange data]. The capability that enables this enterprise-level BOM also ensures that units are made aware of new and modified BOM data in the Army enterprise.

A key element in developing, fielding, and operating GCSS-Army is having a method for receiving BOM data from the activities and organizations responsible for the data. In the data world, the activities or organizations that provide centrally managed data are called authoritative data sources (ADSs) because they manage the creation of and any updates to the data. For enterprise-level BOM data, these organizations are AESIP and the Logistics Product Data Store (LPDS).

Fielded in July 2015, GCSS-Army release 14.2 provides the capability of receiving BOM data from the ADSs. While researchers diligently try to provide the latest and best BOM data, receiving more accurate information from the ADSs will improve data integrity and quality. For this reason and in order to leverage the full capability of ERP integration, the Army's leaders have directed that BOM data structures be centrally managed at the ADS level.

Centralized BOM data management occurs in the Army enterprise from two sources. For sets, kits, outfits, and tools and medical sets from U.S. Army Medical Materiel Agency, AESIP has developed a portal for program managers, materiel managers, and materiel developers to create and modify BOM data structures and components.

For BOM structures for basic issue items, additional authorization lists, components of end items, and on-board spare parts, data management stewards will use the LPDS to communicate the structures from item managers to the tactical users. Based on this arrangement, AESIP and LPDS are the ADSs for enterprise-level BOM data in the Army and transmit BOM structures to GCSS-Army for use by tactical end users.

SERVICE-ORIENTED ARCHITECTURE

In "Business Process Integration with SAP [Systems, Applications, and Products] ERP," Simha R. Magal and Jeffrey B. Word describe service-oriented architecture (SOA) as a capability that provides a flexible application for sending and receiving data between client servers. SOA provides multiple organizations with the same or similar data without drastically changing programming logic, saving time and money.

The capability to centrally manage BOM structures for GCSS-Army hinges on the use of SOA and Government Electronics and Information Technology Association Standard 0007 (GEIA-STD-0007), which were developed alongside the Army's BOM capability for use in the BOM process. This is the first time GCSS-Army has employed an SOA and the GEIA-STD-0007 capability.

The SOA interface uses the GEIA-STD-0007, a standardized data exchange mechanism that uses extensible markup language to send data from the ADSs to GCSS-Army. Once data is received by GCSS-Army, a sophisticated background process verifies the data by analyzing the structures and components using business rules to ensure data integrity is not compromised.

The process will capture and communicate data errors and then send them to the ADS that originally sent the data. The ADS will correct the data and communicate the changes back to GCSS-Army. This process occurs in the background and is unseen by GCSS-Army end users.

END USER NOTIFICATION

For functional users, a component quantity change in a BOM structure triggers an email to the GCSS-Army inbox that notifies users that have the end item on hand in their storage location. This notification contains a detailed BOM change report.

Change reports can be generated using the date ranges of changes, end items, unit identification codes (also known as force elements), accounting requirements code (ARC), and other search parameters. The report will display the end item and component national item identification numbers, end item description, ARC, component description, and new and old values or quantities.

The affected unit's PB01 (shortage annex) work orders also are updated with additional components to reflect any quantity increases that occurred as a result of the BOM changes. Unit personnel must take action in GCSS-Army if they want to order any of the additional authorized components.

GCSS-Army users can also identify equipment that has component data associated with the end items, run reports, order required quantities of materials or tools that were communicated in the change, or dispose of items that were deleted in new BOM structures.

GCSS-Army tactical-level users should expect to manage property accountability in the same manner they did before the migration to GCSS-Army. However, this capability provides a single version of the enterprise-level BOM data that will be used throughout the Army enterprise.

MAKING CONCESSIONS

During GCSS-Army fielding, if component listings do not match the current BOM structure in the Army enterprise or if inconsistencies are identified at the user level, BOM data structures will be adjusted to reflect the ADS BOM structure sent to GCSS-Army. With this approach, property accountability will not be compromised and the component items will remain on the property book but not in the enterprise-level BOM structure.

Once units migrate to GCSS-Army, this capability will impact daily operations positively in several ways. The most notable benefit at the tactical level will be that the system will notify users about BOM changes that will affect the plant maintenance, property book, and unit supply GCSS-Army modules and could lead to procurement of new materials or the disposition of items that were deleted from the BOM structures.

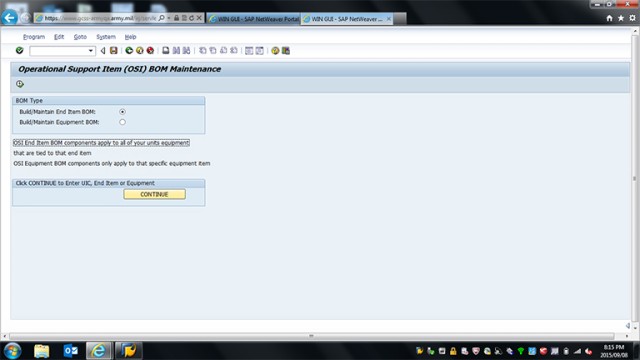

This capability will be complemented by GCSS-Army's ZBOMADD functionality, which will allow users to maintain a list of components that are associated with an end item or an individual piece of equipment as a supplement to the components listed in the ADS BOM.

This unit-maintained component list, referred to as an operational support item (OSI) BOM, is maintained solely by the users in the force element that created the list for property accountability.

Once units add OSI, users can print, change, or delete the OSI if it is no longer required. Although units can modify OSI BOMs, no items on the enterprise-level BOM can be modified or deleted.

Overall, the centralized management of BOM data will revolutionize and modernize logistics functions, while aligning the Army's ERP systems to industry best business practices. An Army enterprise BOM structure has the potential to seamlessly bring unit equipment to current Army-approved specifications and provide the Army with the capability to publish BOM data in near-real time. This will ensure units more rapidly receive the items that they are authorized.

While converting to GCSS-Army, if users suspect errors in BOM structures, they should contact their assigned chief of installation. After conversion, users should contact the GCSS-Army help desk for questions regarding BOM data.

_____________________________________________________________________________________________________

LeQuan M. Hylton is a logistics management specialist and the data team leader for the Global Combat Support System-Army (GCSS-Army) at the Combined Arms Support Command at Fort Lee, Virginia. He is currently on a long-term training assignment at the Federal Emergency Management Agency's Logistics Management Directorate. He holds a bachelor's degree in business management with a concentration in human resources from Virginia State University and an MBA from Averett University, and he is a public policy and administration Ph.D. candidate at Virginia Commonwealth University. He is also an Army Reserve captain and serves as the aide-de-camp for the commander of the 80th Training Command in Richmond, Virginia.

_____________________________________________________________________________________________________

This article was published in the November-December 2015 issue of Army Sustainment magazine.

Related Links:

Discuss This Article in milSuite

Browse November-December 2015 Magazine

Army Sustainment Magazine Archives

Social Sharing