WATERVLIET ARSENAL, N.Y. (August 2015) -- The Watervliet Arsenal and Electralloy announced this month that forging operations at the Watervliet facility have been certified by the American Bureau of Shipping (ABS) to produce stainless steel forgings for marine applications.

The Arsenal and Electralloy have been working together since 2013 in a public-private partnership to produce high-temperature alloys such as nickel, stainless, and Nitronic for a variety of demanding end-use applications.

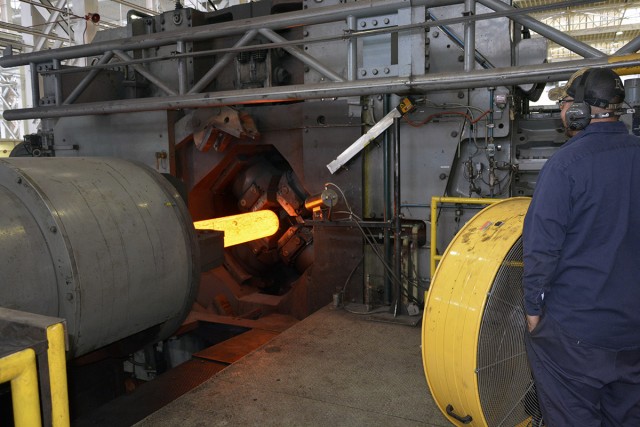

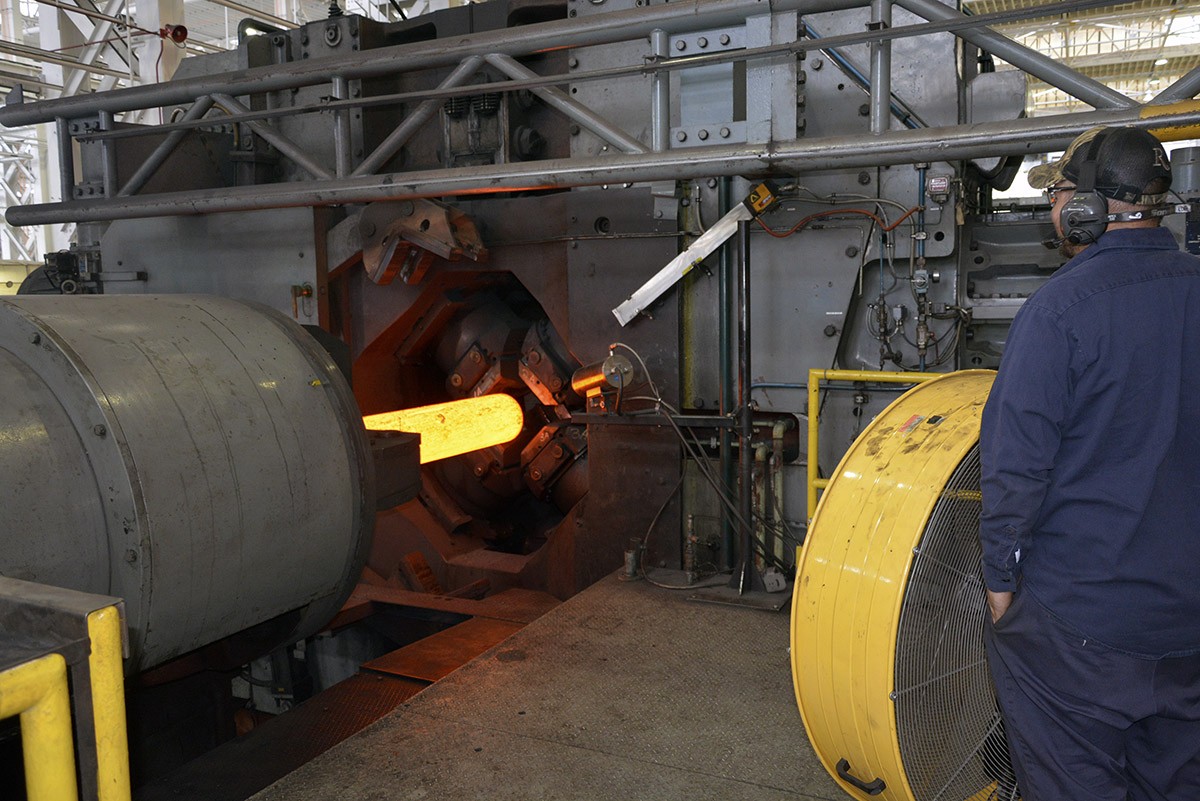

Through this partnership, which was recently renewed for a 20-year period, Electralloy uses the Arsenal's workforce, as well as the facility's rotary forge. Electralloy has just begun operations at its third furnace here.

In the past two years, Electralloy has made a significant investment in upgrades to the rotary forge, charging furnace, the hot-saw, and the infrastructure at the Arsenal, said Tracy Rudolph, President and Chief Operating Officer of Electralloy.

"With the ABS certification, Electralloy can now utilize the Arsenal's world-class rotary forge for the production of specialized, semi-finished tube and bar for use in ship-shaft components," Rudolph said.

Rudolph explained that this production is currently being accomplished by outsourcing the pressing, rolling, and forging to one or more ABS-approved subcontractors. Being able to utilize the approved Watervliet facility will result in improved lead times, a reduction of in-process inventory, improved yields, and improved material properties.

"The ABS certification also expands our ability to pursue additional opportunities in the shipbuilding market for our tube and bar products," Rudolph said.

The benefits of a public-private partnership ...

As intended, the partnership between Watervliet and Electralloy is proving to be beneficial to both parties. Electralloy has been able to make investments in and utilize the Arsenal's forge operations, while the Arsenal has been able to retain critical forging skills in an era of declining defense requirements.

The volume of forging work that Electralloy has generated since partnering with Watervliet has in large part allowed the Arsenal to hire 25 full-time employees who are well-versed in forging operations.

"Given today's era of declining defense dollars, which drives us to make our operations even more efficient, the establishment of non-traditional relationships with private industry makes sense," said Col. Lee H. Schiller Jr., the Arsenal commander. "Today's announcement allows us retain and leverage the unique Arsenal manufacturing capabilities, while creating a synergy between our two organizations. As a result, our combined capabilities will be broader and our manufacturing operations will be stronger."

Electralloy -- G.O. Carlson Inc. company -- is a producer of custom and specialized alloy tubular and bar products that are used in critical, sea-worthy applications, such as the advanced Coast Guard Cutter, aerospace, nuclear, and for Department of Defense applications.

_____________________

The Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest, continuously operating arsenal in the United States, having begun operations during the War of 1812. It celebrated its 200th anniversary in July 2013.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $90 million, and its 2014 revenue was about $117 million.

Related Links:

Story: Army manufacturing centers don't shut down, do they? Not at Watervliet.

Watervliet Arsenal Slideshare Page

Watervliet Arsenal YouTube Page

Watervliet Arsenal Twitter Page

Social Sharing