DUGWAY PROVING GROUND, Utah--A good way to learn more about an Army installation is to ask for a tour. That's exactly what the Salt Lake City Chamber of Commerce did June 30. The goal was a behind the gate, in-depth look at the mission of the test center's facilities, which have a direct impact on local economies.

Joining the tour were members of the Utah chapter of the Association of the United States Army (AUSA), The Utah Army National Guard, The Utah Air National Guard, Hill Air Force Base, the American Red Cross, Zion's Bank and Argosy University, making the tour size about 30 people.

Dugway is a Major Range and Test Facility Base, under the U.S. Army Test and Evaluation Command, located in Aberdeen, Md. Dugway was created in in 1942 with a singular mission: to protect America and its Allies from chemical and biological weapons.

"This is truly a unique test facility. The work we do here cannot be duplicated anywhere else" said Jeff Garcia, chief of the Test Support Division, who provided the command brief at the beginning of the tour. "Last year we had more than 27,000 people come from across the nation and overseas to validate their research."

Garcia noted that for more than 70 years, Dugway's scientists and expert test technicians have tested an array of detectors, protective clothing, decontaminators, and air-filtration systems. Once the data is collected, Dugway issues an objective report, which can lead to acquisition, rejection, or improvements.

The tour included four facilities: the Active Standoff Chamber, Hazardous Materials Test Facility, the Combined Chemical Test Facility, and the Bushnell Material Test Facility.

At the Active Standoff Chamber attendees saw a large environmentally controlled aerosol chamber that provides highly stable conditions to validate biodefense detection systems.

"The chamber creates aerosol clouds, which are contained by transparent air curtains," explained Russell Bartholomew, a physical scientist for the Life Sciences Division. This allows the airflow to be mapped without weather interference, providing testers a much wider variety of conditions without interference, to gather data. The chamber can track the cloud's size, shape, speed, location, chemical content, and particle distribution, he added.

At the Hazardous Materials Test Facility the tour focused on novel explosive devises that terrorists, or even amateurs, might use. These --so called homemade bombs--have become a major concern not only for Soldiers, but for local police officers.

"Unconventional explosives are a growing threat," said Lance McEntire, chief of the Operations Branch. "People don't need to be a chemist to combine ingredients that can harm or kill someone."

McEntire and his team explained how easily some explosive devises could be constructed. Then to the surprise of most attendees, he showed a few of a number of known terrorist magazines, which included lists of ingredients and easy to follow directions for assembling bombs, found on the internet.

Several people expressed gratitude for Dugway's efforts to identify an emergent threat.

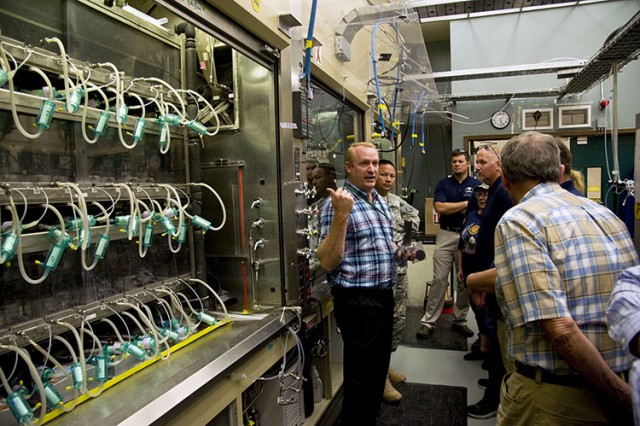

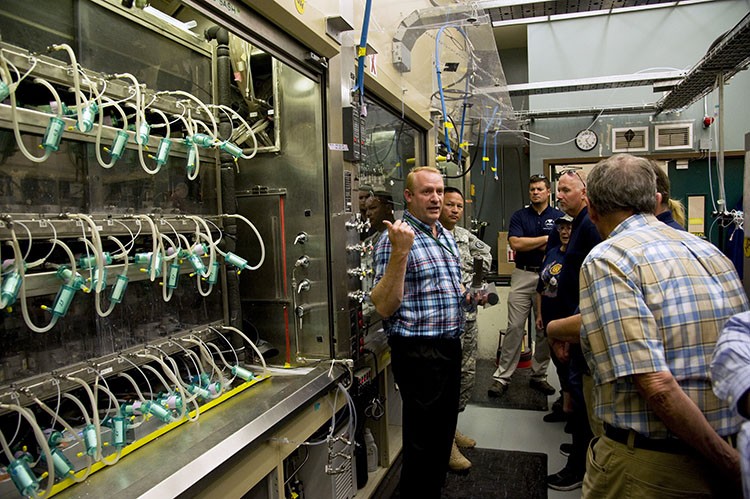

The Combined Chemical Test Facility was the next stop. There, attendees met Dr. Chris Olson, the director of the Chemical Test Division.

"Testing here uses complex real-time detection and monitoring. We test detectors, protective clothing, air filtration systems, respiratory masks, and decontamination systems to make sure our Warfighters have the right protective equipment every time they need it," he said of the 35,000-square-foot building supports chemical testing using agents or simulants in liquid, vapor, or aerosol form to verify the ability of military equipment to function in a chemical environment.

Olson noted that the facility is widely known for its redundant safety features.

"The exhaust system, for example, has multiple fans, controls and alarms, which provide airflow through fume hoods used for all agent and simulant testing," he said.

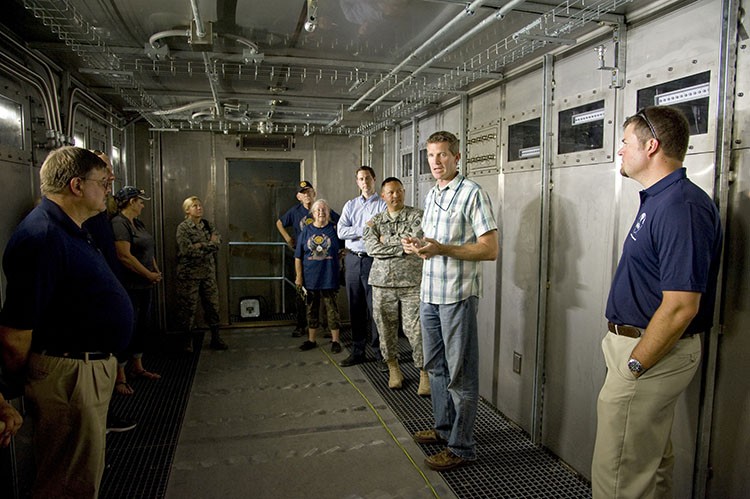

The final stop was at the Bushnell Material Test Facility, where Adam Rogers, chief of the Chemical Test Branch, lead the tour.

This is a highly secure test structure, he noted, as attendees were lead through several gates. Inside, they learned about the chamber's capability to test detection and decontamination systems. The largest chamber, which is more than two stories high, can easily hold an armored vehicle or a helicopter.

"The chamber challenges defense systems in a wide range of temperatures, humidity levels and can easily identify interferents, such as dust, smoke, and exhaust," he said.

Rogers pointed out that the largest chamber was undergoing some internal construction. Two additional smaller chambers are being added to either side, which will meet the "next generation" requirements for testing he said.

"We do so appreciate the efforts to share this information with us," said Lt. Col. (retired) Claude McKinney of the AUSA Utah Chapter, who helped organize the tour.

McKinney's feelings of appreciation appeared echoed by each tour member at the end of the tour. Many attendees expressed that they had a much clearer understanding of Dugway's mission.

"Truly amazing infrastructure for our Soldiers and our nation," was McKinney's final summation.

Social Sharing