TOBYHANNA ARMY DEPOT, Pa. - Tobyhanna employees have restored more than 1,000 electronics repair shelters and vans to like-new condition through the Army's Electronic Shop Van (ESV) Recapitalization Program.

Four years into the program, which is part of Army Transformation, the depot has overhauled 701 AN/ASM 146 and147 shelters and 320 AN/ASM 189 and 190 vans with $115 million Reset and Recap program funds.

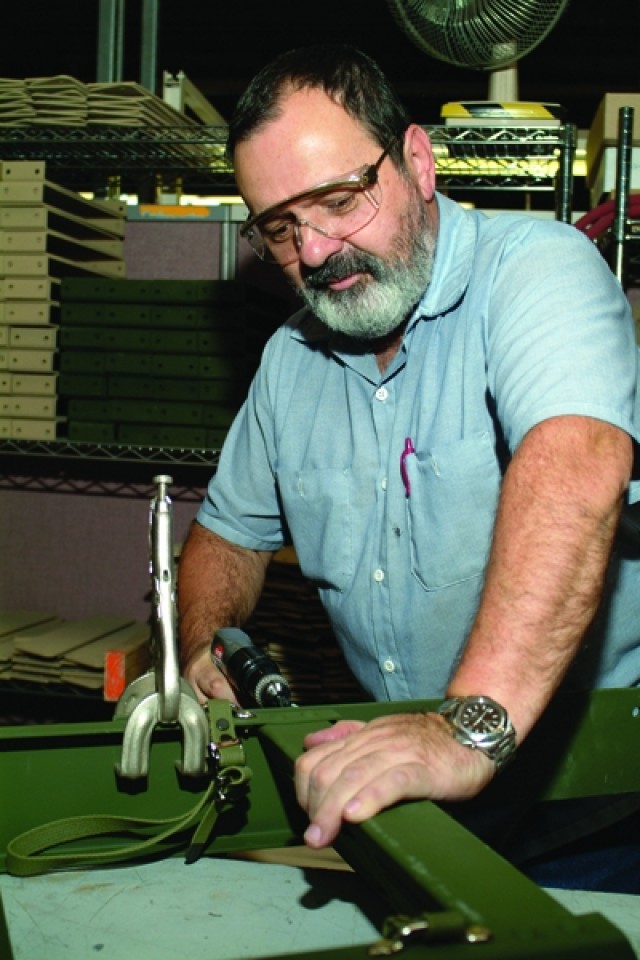

Several shops and hundreds of employees joined forces to completely disassemble the shelters and vans. The ESVs are stripped, repaired and painted, and equipment is repaired and replaced. Sheet metal is also replaced or repaired, tested for leaks and painted.

The AN/ASM 146s and 189s are the primary maintenance facilities for the entire Army electronics maintenance mission in combat service support units. They provide facilities for testing and repair/calibration for avionics, communication, electronic, navigation, photographic, and infrared systems.

The AN/ASM 147s and 190s are mobile shelters and vans, respectively, which provide accessible, forward-based storage of spares requirements for the systems repaired in the 146 and 189 shelters and vans.

"All the employees should be extremely proud of their product, and its impact to the warfighter's ability to repair electronic components in the field," said Frank Kaczmarek, Systems Integration and Support Directorate director.

Workers have also reduced production costs by implementing suggestions that improved processes.

"They work hard at what they do and offered many suggestions that contributed to the lower unit-funded cost (UFC) of the shelters and vans which led to additional workload. I'm extremely proud of their efforts and look forward to the challenges of next year.

Kaczmarek acknowledged that during the first three years of the program the depot was required to reduce the UFC by 10 percent each year. Lean events have also produced multiple savings to the program," he said.

"The UFC, although not reduced as a whole, was reduced for the labor portion each year and we expect further reductions," he said. "We can only truly control the man-hour portion of the UFC. The cost of materials such as plywood, insulation and raw materials are subject to market prices, which have grown in the last five years."

Tobyhanna has been involved in this program since its inception, initially producing the modification work order and new technical manuals. Employees spend an average of 70 days inserting new technology and providing upgrades to the shelters; 100 days for vans. The standard timetable for repairs is 90 and 120 days, respectively.

"The results of all your efforts are providing our warfighters with the assets to rapidly and effectively fix electronic systems and components in the field," said Frank Zardecki, deputy depot commander, during an award ceremony Dec. 18. "With our commitment to continuous improvement, the product we finish today is done faster and more efficiently than one produced in 2003. That is because of hard work and good ideas, and we all are most appreciative for what you have achieved," he said.

It's important to note how Tobyhanna and the ESV partners have diligently worked to reduce the UFC and to build in greater quality and reliability in this complex effort, said Col Ron Alberto, depot commander. "This is one of our most critical projects and it reflects the total capabilities-from design to manufacturing to technology insertion and system integration-that Tobyhanna can bring to meet the most urgent needs of our Army," he added.

Zardecki pointed out that the ESV Recap and RESET program is one of Tobyhanna's largest workloads. The latest figures show that since starting the program in FY 03, the project has consumed more than 1,250,000 feet of wire, 20,000 square feet of wood countertops and more than 1.1 million wood screws. Stretched end to end, the wire would run more than 235 miles, almost from here back to Army Materiel Command (AMC) Headquarters at Fort Belvoir, Va.

After the shelter is repaired and painted, it undergoes pressure tests to make sure it's water tight, and then basic electrical equipment is installed, inspected and tested before the remaining items are installed. For the AN/ASM 146 and 147, that means replacing the air blowers with 9,000 Btu environmental control units and installing items such as new signal entrance panels, backup batteries and emergency lighting. Outdated file cabinets and dehumidifiers were removed and power entry panels and power distribution boxes were updated.

Technicians manufacture racks, straps and braces to support upgrades to shelter and van systems. As part of the power service improvements, three-phase power was added, requiring re-wiring of the entire van or shelter. Other upgrades include improved power entrance box connectors, Single Channel Ground and Air Radio Systems antenna interfaces, and run-time meters. Access to a Local Area Network and remote telephone connections are now available.

Ideas for the modifications and upgrades in the vans and shelters came from listening to the customer and by surveying the Soldiers who will work in the ESVs, according to Alberto, who also said the facilities are safer, more user friendly and more reliable.

"The upgrades and modifications bring the shelters into this century," said Francis Koenig, Systems Overhaul and Support Branch chief. "Now, Soldiers in the field can repair anything, anytime."

For instance, the 147s had small heaters and no air conditioning, according to Koenig. Now the shelters are getting environmental control units, which provide both. Other changes include new phone systems, new cables to support computers and increased direct current amperage.

"The workers on the line are some of the hardest working people across the trades," said Steven Mikitka, Electrical Recap Support Branch chief. "Carpentry, electrical and sheet metal personnel all work side-by-side to accomplish the mission simultaneously."

"We [Tobyhanna] provide the work center they [the Soldiers] can function in," said Bret Hunt, logistics management specialist, Command, Control, Guidance and Support Scheduling Division.

Product Manager Force Sustainment Systems (PM FSS), Tobyhanna Army Depot, Communication-Electronic Life Cycle Management Command, and the Army's Office of the Deputy Chief of Staff are key players in the program that also is incorporating several reliability and supportability initiatives as well as safety fixes.

PM FSS, located at the U.S. Army Soldier Systems Center in Natick, Mass., has overall responsibility and oversight of the program.

"In our eyes, Tobyhanna sets the standard for Lean Six Sigma and what it represents," said Maj. Richard Hall, lead manager for the ESV program. He explained that by incorporating Lean concepts into the modified work orders, the depot provides the capabilities the Soldiers in the field need and want.

The electronic repair facilities have been fielded since the 1970s, according to Hunt. He explained that during that time there has never been a serious Reset or rework program for the shelters and vans.

"Some of these vans haven't seen the inside of a depot since the '70s," said Hunt. "They've never been brought in and updated with the new technology."

The recapitalization program began full production in Fiscal Year 2003 and is scheduled to continue through 2009.

"Thank you for what you're doing from everyone who wears a uniform," said Gen. Benjamin S. Griffin, commander, AMC. "Keep doing what you're doing.

"I'll keep the resources coming, you keep production up and all the other agencies will make sure you get the parts you need.

"I'm optimistic that you can continue to build on Tobyhanna's great reputation," he said. "There's a dynamite team here that will take the depot where it needs to be for the future."

Tobyhanna Army Depot is the Defense Department's largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network. Tobyhanna's missions support all branches of the Armed Forces.

About 4,400 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army Communications-Electronics Life Cycle Management Command (C-E LCMC). Headquartered at Fort Monmouth, N.J., C-E LCMC's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing