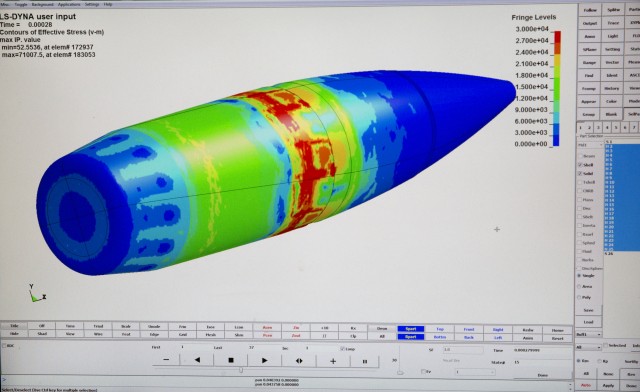

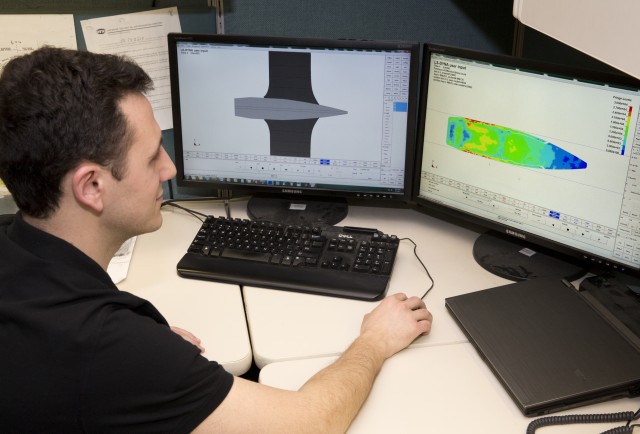

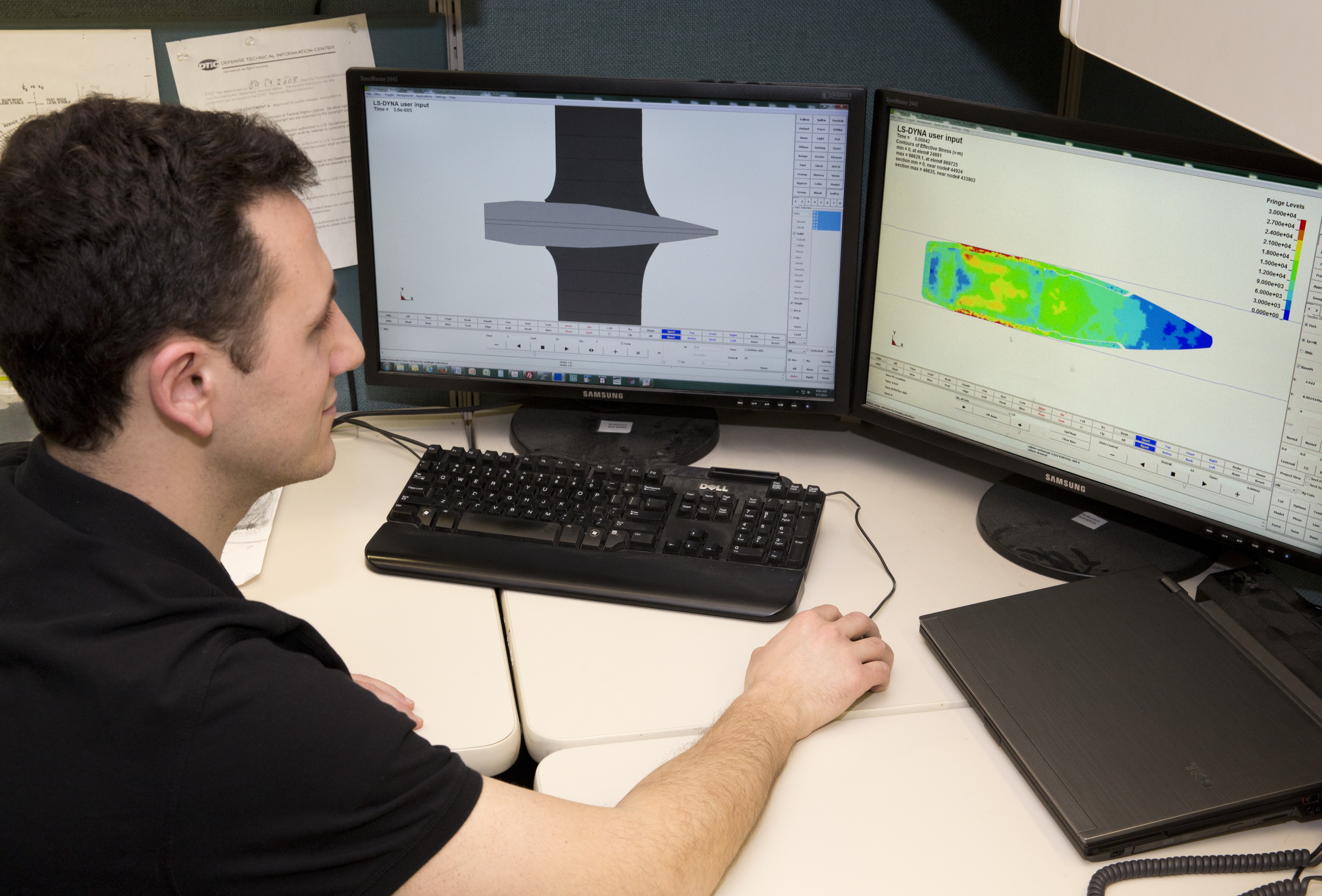

PICATINNY ARSENAL, N.J. (May 19, 2015) -- With the steady increase in computing power, engineers are able to improve lethality with sophisticated computer models by eliminating unworkable designs.

Mechanical engineers can understand the effects different caliber ammunition will have on targets.

"We are able to get a more detailed small-caliber lethality analysis with more advanced computer technology, by quantifying the numerous constituents of a ballistic event ending in the incapacitation of an individual," said Mark Minisi, technology team leader at the Small Caliber Munitions Division of the U.S. Army Armament Research, Development and Engineering Center, or ARDEC, at Picatinny Arsenal, New Jersey.

"It takes a significant complexity of computer power," Minisi said.

Powerful computers, Minisi said, "help tackle larger problems and tackle more problems at once."

The research center's portfolio handles nearly 90 percent of the Army's lethality projects and all conventional ammunition for joint warfighters. One of the product groups include small-arms weapons systems with everything from 9 mm pistols to .50 caliber heavy machine guns.

With the release of the Army's newest 5.56 mm bullet, the M855A1 Enhanced Performance Round, or EPR, researchers reached a milestone.

"Consistency and internal performance of EPR was accomplished through a combination of modeling, simulation and testing," Minisi said. "The use of newer, faster computers made critical portions of that effort possible. Some data was statistical, some physical and some probabilistic, but all done using physics-based models to simulate ballistics on soft targets."

ARDEC engineers partner with the other RDECOM organizations like the U.S. Army Research Laboratory Survivability/Lethality Analysis Directorate at Aberdeen Proving Ground, Maryland.

"We frequently work with them on evaluation and development efforts," Minisi said.

ARL scientists conduct analytical investigations, modeling and simulations, and laboratory and field experiments to provide its analyses as well as technical advice and to be subject-matter experts on survivability and lethality matters to program executive officers and program managers, users, testers, the Army's independent evaluator and other customers.

Their products support milestone decisions concerning critical operational survivability and lethality issues for Army systems with critical survivability issues that could affect Soldiers' lives. To best serve the Army's analytical needs, ARL leverages both research conducted throughout RDECOM, as well as other services.

Computer technology and software significantly minimize product development time by helping engineers to greatly reduce the number of prototypes, Minisi said.

Large caliber system analysis has taken advantage of computational simulation tools for years, while smaller caliber systems are starting to catch up, he said. The lag was a result of the cost differential in prototyping and testing between artillery and rifle munitions.

Prototypes can cost millions of dollars a piece. Modeling and simulation can save money by avoiding costly prototypes and testing.

"They can't just go make 20 and destroy them. They require a higher level of science," he said.

"In five years we might be down to three or even two prototypes," he said.

Engineers validate terminal performance models that cover a wide range of target variation through the use firing against a subset of targets and ensure the model is predictive.

A simulation that would have taken a team of engineers more than a week to prepare 10 years ago now takes 20 hours.

"I do not see an end to this continuous improvement," Minisi said. "We can make predictions with a high degree of confidence."

At one time, the computers the engineers first used were 32 processors and would average a cost of $500,000. Today, the center has computers with more than 100 processors averaging about $100,000 per unit.

Minisi said ARDEC has been working with programs, like Operational Requirement Based Casualty Assessment, known as ORCA. The program is the Army's premier tool, allowing assessments of Soldier performance following weapon-induced injury.

The ORCA modeling system incorporates previously developed, as well as newly developed injury criteria models, algorithms and scoring systems, to characterize human bio-response to trauma from various types of battlefield insults and derives estimates of Soldier performance degradation.

"They more we can do, the more we can realize all the things we can't do," Minisi said. "I can't model a whole human body … but we are much closer than we were 10 years ago."

---

This article appears in the May/June 2015 issue of Army Technology Magazine, which focuses on Future Computing. The magazine is available as an electronic download, or print publication. The magazine is an authorized, unofficial publication published under Army Regulation 360-1, for all members of the Department of Defense and the general public.

The Armament Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to empower the Army and joint warfighter with technology and engineering solutions that ensure decisive capabilities for unified land operations. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Documents:

<b>Army Technology Magazine</b> [PDF]

Related Links:

<b>Online:</b> Army Technology Magazine

U.S. Army Armament Research, Development and Engineering Center

Army.mil: Science and Technology News

Social Sharing