HUNTSVILLE, Ala. (Apr. 23, 2015) --- Students throughout northern Alabama competed in the inaugural Switchblade Competition April 23 at the University of Alabama in Huntsville.

Each team was required to redesign the blades of a windmill to adjust to the low power wind conditions of Alabama. Senior Systems Engineer Bill Pannell, from the U.S. Army Aviation and Missile Research, Development and Engineering Center, came up with the idea while experimenting with a windmill used for military operations in Afghanistan.

Students from Alabama A&M University, Columbia High School, Hartselle High School and the University of Alabama in Huntsville received a $500 stipend to fund their project.

"The Switch Blade Competition is a great example of how we're trying to make the quest to 100 percent clean energy in the Huntsville fun," said Daniel Tait, chief executive officer, Alabama Center for Sustainable Energy. "Students get to engage with some of the toughest problems we need to address as a community while gaining hands-on experience with real equipment being used by the U.S. Army."

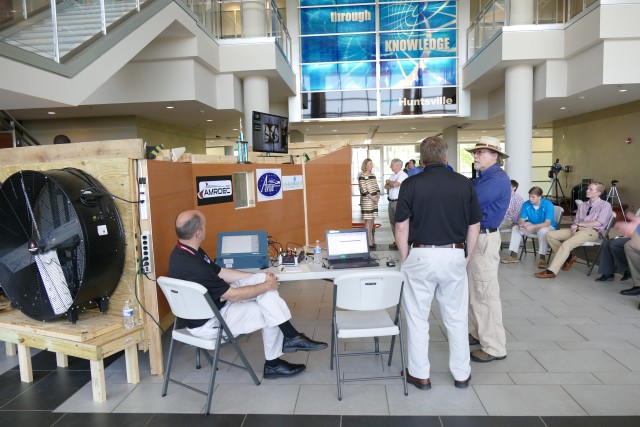

A wind tunnel was used to bring in a large volume of air, with two large fans pulled the air out at the back end of the wind tunnel. Students placed their blades on a stand mount near the wind generator to allow the blades to generate electricity. The electronics team built a computer measuring system to calculate the output of electricity each wind turbine blade-set generated. For three sessions, each team's blade was tested at wind speeds of 14 miles per hour for several minutes.

Randy Buckner, Director of Research and Development, Avion Solutions Inc., constructed the wind tunnel. "As part of the Energy Huntsville Initiative, we needed a way to measure the wind flow across the windmill blades," Buckner said. "We were able to design the tunnel for 14mph winds which is common in the Huntsville area and make it mobile and easy to put together. After the competition, this wind tunnel will be available for the public in the future for anyone that wants to use it for community projects."

Blades could be no more than one pound each and only a few inches longer than the existing blades. Students were encouraged to use materials of their choosing in the creation, design, and manufacturing of the blade.

The UAH Green Wind Power Available at Low Speed, GWPALS was the winning team that created the most energy. Their additive manufacturing blades tested in typical Alabama low wind conditions 44 percent better than the factory blades. Team members included Sam Cordner, Cameron Blalack, Steven Doyle, Allison Luther, and Benjamin Easterwood.

"This is amazing. We were hoping to outperform the original blade, we predicted we would and we did and it was with excellent success," said GWPALS CAD Designer, Sam Cordner.

"This was definitely a team effort and the team dynamics worked out. A lot of effort went into the scope of the project because it constantly changed but above all it was fun," said Cameron Blalack, Senior Mechanical Engineering Student and the GWPALS' Project Lead.

Competition sponsors included the U.S. Army Aviation and Missile Research, Development and Engineering Center, Alabama Center for Sustainable Energy, Avion Solutions, the University of Alabama in Huntsville and the Huntsville Chapter of the Association of Energy Engineers.

---

AMRDEC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers. AMRDEC employs nearly 11,000 civilian scientists, researchers, and engineers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Social Sharing