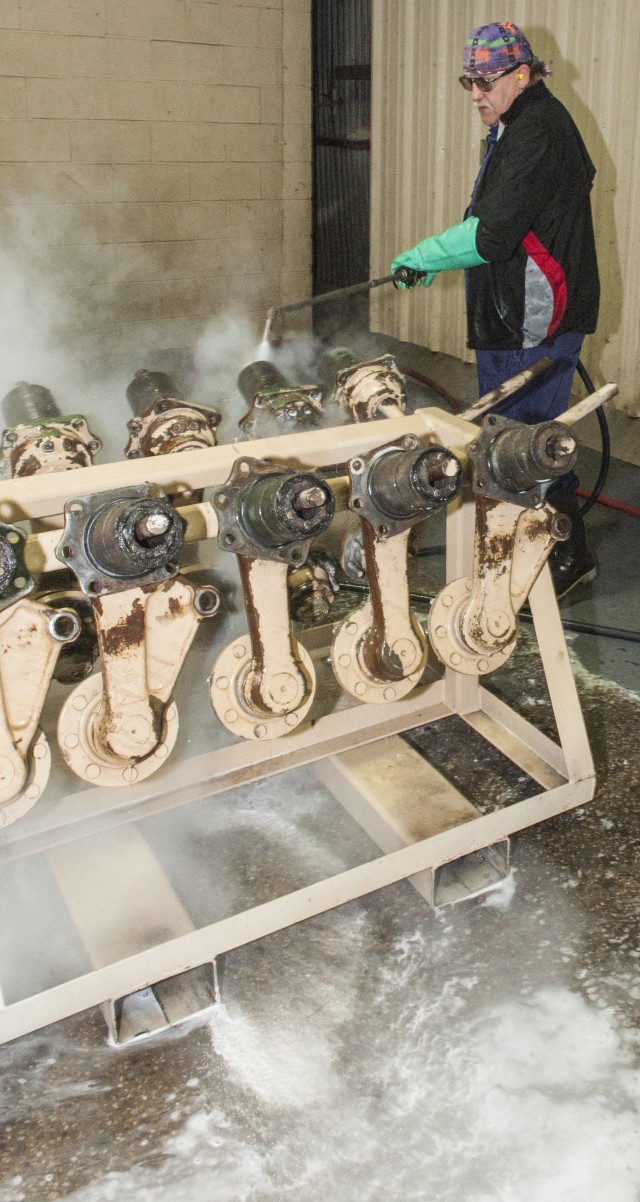

ANNISTON ARMY DEPOT, Ala. -- With five locations throughout the Nichols Industrial Complex, the depot's Steam/Chemical Cleaning Branch is in just the right place to assist with vehicle and weapon system production.

"We normally touch every vehicle and artillery piece more than once," said Glen Smith, acting supervisor for the installation's wash racks. "On average, we wash items between two and four times."

Most combat vehicles are washed following disassembly, again after any welding repairs, after machining, then following assembly and testing as they are prepared for final paint.

Each wash is designed to get rid of oil, grease, welding slag and other residue to ensure the overhaul, repair and paint processes can proceed.

"This operation and the employees working there are the backbone of our industrial processes," said Patti Sparks, process optimization manager for the Cleaning and Finishing Value Stream. "The wash protects the environment from oils, fuel and other contaminants and assists shops to determine necessary repairs."

Each of the five locations has its purpose.

A hurricane wash in the Engine Sub-Assembly Shop is used to cleanse large baskets of items and any components slated to be discarded.

A small area attached to the Turbine Engine Shop cleans the cases that engines are stored in and some of the engine components.

A wash area near the test track assists with overflow parts and is also used by contractors on the installation.

At the Vehicle Component Repair and Paint Facility is an area consisting of bays for suspensions and other combat vehicle components.

The largest wash rack, located near the Combat Vehicle Repair Facility, is capable of cleaning entire vehicles.

Despite the amount of water and steam used for this necessary process, washing vehicles and equipment is a dirty job, and one which can be dangerous at times.

"When it's cold, you're extra cold and when it's hot, you're extra hot, because you are working with steam," said Smith, adding that weather can shut down operations, particularly lightning.

All seven permanent employees in the branch are Veterans and the organization regularly borrows employees from other cost centers to accommodate the production schedule and urgently needed items.

"I've worked with a lot of people here at the depot," said Smith. "These employees are some of the best I've worked alongside."

Social Sharing