Fort Indiantown Gap National Guard Training Center (FTIG) is a 17,150-acre military installation that provides training while simultaneously sustaining a vital habitat for rare native flora and fauna. The installation successfully accomplishes both by thinking big--using a wastewater plant product to fertilize 25 acres of hay--but not losing sight of small things like a special species of butterfly.

The installation's efforts have not gone unnoticed; FTIG won a Secretary of the Army Environmental Award in the "Sustainability--Non-Industrial Installation" category and will go on to compete at the Secretary of Defense Environmental Awards level.

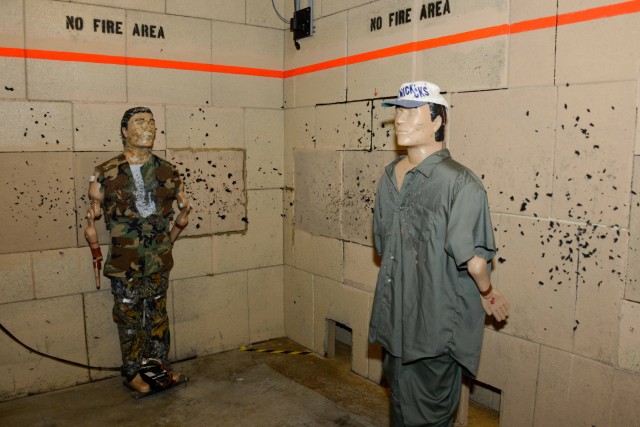

This Pennsylvania National Guard (PNG) facility is the only live-fire maneuver military training facility in the state. It supports more than 19,000 PNG personnel each year; other branches and components of the military as well as government and law enforcement entities training at the installation swell that number of users to over 230,000 each year.

"All FTIG Sustainability Program projects are intended to protect and enhance training and readiness capabilities now and in the future," said Lt. Col. Robert Hepner, garrison commander.

"Sustainability is instilled in all departments and directorates, promoting organization-wide accountability and ownership. The sustainability ethic and extensive training help ensure full environmental compliance at FTIG."

FTIG's Sustainability Program achieved several milestones over the past two years. One is its reuse of recovered sewage sludge for sustainable landscaping. A sludge press was installed at FTIG's wastewater treatment plant in 2010; the following year, a permit was obtained that allowed the installation to reuse the resulting sludge (biosolids).

From 2012--2014, the sludge fertilized approximately 25 acres. The fields produce Timothy hay, which is used for sedimentation control, erosion repair, construction and land stabilization. This eliminates costs associated with disposing of the sludge and the cost of purchasing hay for construction projects. Diversion of sewage sludge from the landfill alone saves nearly $20,000 each year.

Another milestone is the installation's recycling efforts. Waste diversion remains a key PNG goal. Last year, FTIG exceeded its goal and should meet or exceed this year's target. Everything except glass is recycled, including batteries, tires, oil and antifreeze. Qualified Recycling Program (QRP) revenue from items such as kitchen grease, cardboard and brass amounted to more than $281,000 in 2013 alone and supports expansion of the recycling program; health and safety initiatives; and morale, welfare, and recreation purchases.

One unique challenge for the training site was what to do with the rubber backstops used behind targets on the firing ranges. Blocks capture the lead rounds and prevent ground contamination but are then lead-contaminated. Sustainability Program staff located a specialty smelter in Minnesota that grinds the block, recovers the lead residue, and recycles all the components. PNG pays to transport the blocks but spends about 70 percent less than disposing of the hazardous waste.

Concrete from demolition projects is crushed and used for road material and on erosion control projects, and paint slated for disposal goes to the installation's paint shop to determine if another facility can use it. The Sustainability Program also negotiated contracts for free pickup of used oil and antifreeze.

For several years, the installation has focused on eliminating heating oil tanks in favor of natural gas conversion--a greener, cheaper alternative.

"In one year, the conversion saved the installation more than $1 million in utility costs," said Hepner. "Additionally, more than 400 storage tanks were removed, which saves hours of inspections and servicing, improves the heating systems' efficiency, and minimizes environmental liability."

FTIG continually strives to become self-sustaining. It is seeking grant funding to support a joint project with a contractor to construct a 17-acre solar field. Under a unique agreement, the contractor pays the costs of installing the field and resells energy to FTIG. After approximately 10 years, FTIG would own the solar field.

Rather than routinely starting the installation's many emergency generators to test and maintain them, sustainability staff members work with local utilities so these events supply energy for the installation during peak demand times. In return, FTIG receives energy cost subsidies. Staff members also conduct energy audits on-site and elsewhere in the state to identify energy hogs, develop costs of retrofitting older facilities and acquire more energy efficient equipment.

Part of the installation's wastewater collection system is 70 years old, but 85--90 percent of the training site's pipe system has been upgraded to prevent groundwater from leaking into the wastewater system. QRP funds pay for automated samplers to ensure federal compliance.

Rehabilitating older structures involves Leadership in Energy and Environmental Design (LEED) guidance to enhance energy/resource savings and efficiency and all personnel are encouraged to replace hazardous materials with green substitutes whenever possible.

Local, regional and state involvement is also a priority. Sustainability staff members share their expertise with environmental committees in the region and at the National Guard Bureau level.

FTIG is an open post with a robust hunting and fishing program, a rich cultural and military history and diverse fauna including a population of Regal Fritillary butterflies which are either extirpated or critically endangered east of the Mississippi.

The installation hosts events and conducts special projects to beautify and maintain its unique natural and cultural features. Annual Earth Day activities include displays and presentations that emphasize recycling and energy conservation. FTIG also hosts booths with educational displays and materials at area and state events.

The installation's Army Compatible Use Buffer (ACUB) has led to relationships that help expand the Sustainability Program's capacity for outreach and education.

Sustainability Program accomplishments do more than free up resources to support other mission needs. They reflect the importance the PNG places on sustainability and ensure FTIG remains an environmental leader in the region.

Social Sharing