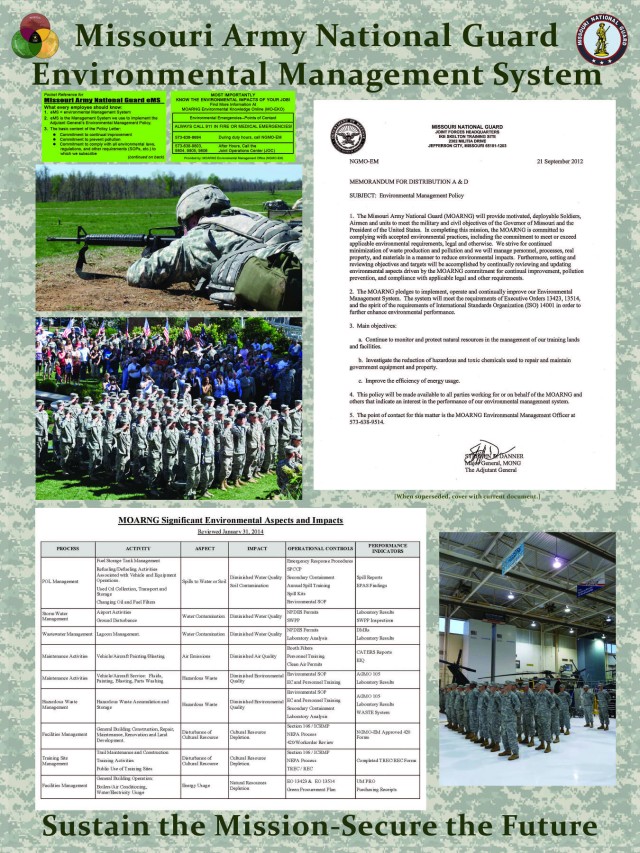

The Missouri Army National Guard (MOARNG) Environmental Quality (EQ) program, which is overseen by the MOARNG Environmental Office, is responsible for the environmental quality of 19 unique industrial facilities that provide equipment and vehicle maintenance for the MOARNG and regional support for aviation equipment across 14 Midwestern states.

That may sound ordinary, but what the MOARNG Environmental Management Office has accomplished over the past two years is anything BUT ordinary. For example, during the last external Environmental Performance Assessment System (EPAS) audit by the National Guard Bureau, the EQ program's industrial installations received high marks for environmental compliance and stewardship, including zero findings at the Combined Support Maintenance Shop and positive findings at the Aviation Classification Repair Activity Depot (AVCRAD). Even better, in the same audit, the eMS program tied the highest marks ever assessed, with 44 of 46 findings positive.

"For Missouri's Environmental Program to be recognized not only as the best in the National Guard, but the best in the Army is a tremendous achievement," said Maj. Gen. Steve Danner, Adjutant General of the Missouri National Guard.

"I'm very proud of the great efforts by our Soldiers, who are responsible for 19 industrial facilities across the state, including an Aviation Classification Repair Activity Depot. These Missouri Guardsmen have successfully integrated environmental stewardship into all levels of operations at all phases -- enhancing our readiness while optimizing our responsible resources usage."

The EQ program also achieved important milestones, such as conducting internal EPAS assessments at 100 percent of the industrial installation facilities each year, well beyond the mandated 25 percent review. These internal inspections not only led to exemplary compliance, but also allowed EQ staff to develop effective working relationships with each facility's staff. A continued commitment to integrate the MOARNG eMS program into all operations also contributed to the EPAS success.

The efforts of the MOARNG Environmental Management Office were outstanding enough to secure a Secretary of the Army Environmental Award in the category of Environmental Quality--Industrial Installation. The next level of competition is the Secretary of Defense Environmental Awards.

"Our success can be contributed to our Environmental Management System," said Lt. Col. John D. Jurgensmeyer, environmental management officer. "Our eMS involves leadership through our Environmental Quality Control Committee (EQCC), which is chaired by Brig. Gen. James Robinson, the chief of staff, directorates, and senior commands.

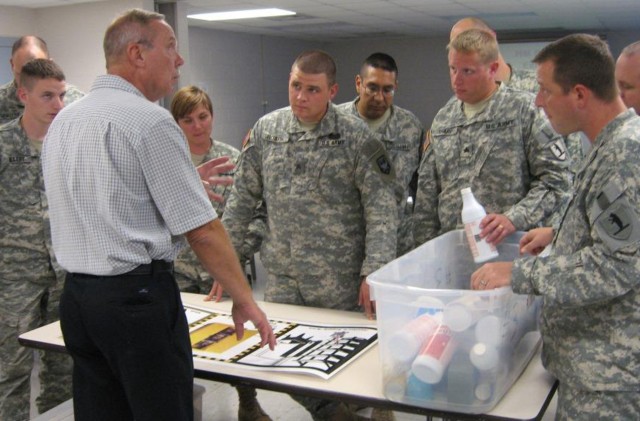

"This coupled with our extensive environmental training and annual audit programs provide valuable feedback to the EQCC," said Jurgensmeyer. "None of this is possible without the cooperation and involvement from our Soldiers. Together through our eMS, we have been able to consistently meet our environmental goals."

EQ program staff members each have an area of specialty--from hazardous waste management to recycling to clean air management, and others. They work with unit environmental coordinators at each site and facility to ensure compliance and continual improvement, as well as provide training to 375--400 environmental coordinators and support staff statewide each year. In addition to their daily duties, program staff helps the eMS program manager set objectives in their area of specialty and help formulate strategies to achieve them.

The EQ program also receives support from the Environmental Quality Control Committee, which responds to issues briefed by the EQ program. This year, based on EQ staff recommendations, the MOARNG quickly closed a non-essential bulk fuel tank at a Field Maintenance Shop (FMS), which reduced environmental liability and eliminated the need for a spill prevention, control and countermeasure plan.

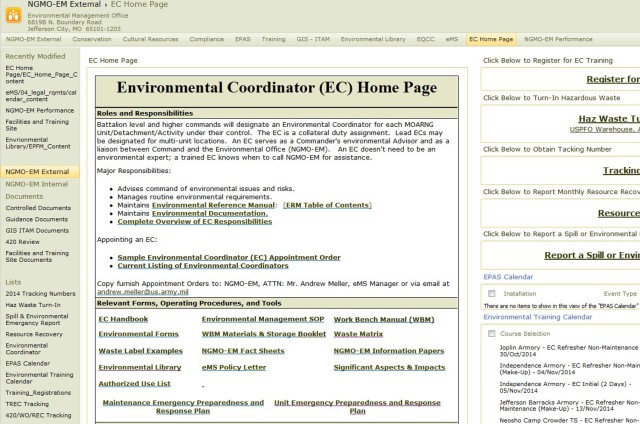

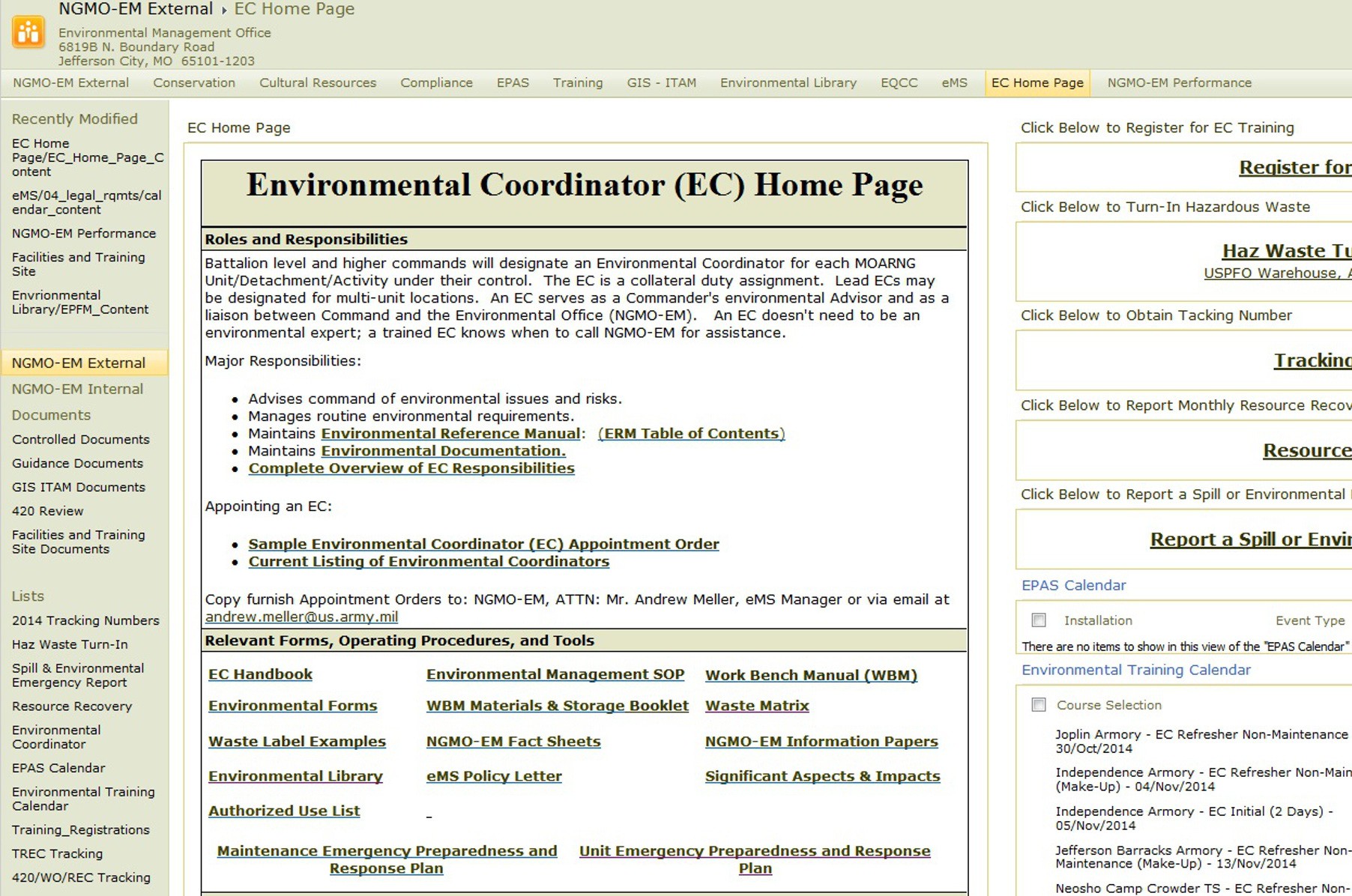

Technology plays an important role in executing program goals. A dedicated eMS SharePoint portal was established for facility environmental coordinators. It serves as a central repository for training materials, compliance forms, environmental reports, etc., with site-specific data links.

All staff with an EQ responsibility can use the site to communicate with other facilities, environmental staff and compliance staff. Training packages are on the site to provide easy documentation of training certificates. The eMS portal allows the EQ program to identify facilities that need environmental support, training or correction.

The EQ staff's geographical information systems (GIS) program allows the Environmental Office to provide MOARNG Soldiers with training maps that show fuel points, oil-water separators, storm water outfalls, and wetlands, along with expectations for management and protection of these elements. This communication and support of Soldiers' day-to-day operations enhances their ability to meet the MOARNG training and readiness missions.

Over the past two years, the EQ program continued to focus on elimination of waste streams and improved material management. The 2013 efforts resulted in recycling 260,000 pounds of scrap metal, 80,000 pounds of tires and 80 pounds of toner cartridges; similar totals are anticipated for 2014. The installation also recycles metal-encased filters as scrap, diverting 6,000 pounds of oil filters each year. The AVCRAD implemented a pharmacy program; rather than each section maintaining independent inventories, the pharmacy provides material sharing and compilation of orders.

Also, the MOARNG's industrial installation participated in the pilot Army Oil Analysis program, sampling and testing vehicle and equipment oils. Early data indicate it may become official, thereby reducing oil usage, handling and disposal concerns while minimizing the risk of spills. The installation recycles about 15,000 gallons of used oil annually.

Currently, eMS objectives focus on reducing energy use on the industrial installation. The EQ program supported adopting a 4-day, 10-hour workweek at MOARNG facilities, which achieved a 10 percent decrease in energy use.

Fostering strong working relationships with Missouri Department of Natural Resources (MDNR) has also allowed the EQ program to reduce environmental compliance costs for the installation. For example, the EQ program negotiated a statewide Clean Water Act land disturbance permit that eliminates the need for individual permits in the course of ordinary operations, saving the MOARNG $3,000 to $5,000 annually.

Similarly, the EQ program drove the acquisition of a new paint minimizer system for the Combined Support Maintenance Shop and AVCRAD. Based on a careful comparison, bringing these operations in-house meant a payback period of less than two years. Over 10 years, acquiring the paint minimizer system saves nearly $19,000.

Program staff facilitated transfer of ownership and accountability of an onsite electrical distribution system at Camp Clark to the local power provider, thereby eliminating maintenance costs and potential environmental issues for the MOARNG.

In 2013, the EQ program was key to five military construction projects, investing nearly $20 million in the MOARNG installation. Program staff was involved in the process from conception through completion to encourage adoption of sustainable features and ensure full compliance. The EQ program reviews every proposed action for construction and maintenance and, at any point in the process, can check the MOARNG SharePoint site and see the project status.

Preserving internal Environmental Office continuity has been a key element of the MOARNG EQ program, and the SharePoint site, in conjunction with the extensive training modules available online, allows new staff to get up to speed quickly on all activities.

The installation staff also transfers its lessons learned by allowing other state Guards to visit the installation; participating in various partnerships, teams and working groups that bring together regulatory stakeholders, military entities and local industries and businesses; participating in forums and advisory groups; and hosting job fairs to encourage awareness of environmental careers with the MOARNG.

Additionally, EQ staff hosts groups of schoolchildren for installation field trips, often with a focus on environmental awareness and pollution prevention, and allows Lincoln University (Jefferson City) college classes to use MOARNG training sites and facilities as field classrooms.

The EQ program oversees the MOARNG's industrial installation Spill Prevention, Control, and Countermeasures plans. All other environmental-related plans are reviewed and updated regularly. Adhering to these plans directly supports the MOARNG's compliance record.

Related Links:

Secretary of the Army Environmental Awards

Social Sharing