The U.S. Central Command Materiel Recovery Element (CMRE) had the task of retrograding, redistributing, and disposing of more than 50,000 20-foot equivalent units (TEUs) of Army equipment that had accumulated after a decade of war in Afghanistan. This proved to be a monumental task that showcased the U.S. military's logistics strength. It also changed the way planners think of retrograde operations on such a vast scale.

The task was further complicated by the fact that Afghanistan is a landlocked country. To get around being landlocked, the military used a combination of strategic air assets, truck routes to ports in Pakistan, and the Northern Distribution Network, which is a complex chain of transportation by truck, rail, and sea that meanders through Northern Afghanistan, Asia, and Europe.

THE CMRE MISSION

One of the main goals of the CMRE mission was to bring Army property to record by sorting, inventorying, and counting containers, processing materiel for retrograde, and ultimately shipping equipment back to a military depot to be put back into the Army supply system. This retrograde process accounted for only part of the equipment in theater.

Another portion of the equipment was transferred to Afghanistan through the foreign excess personal property process, disposed of as general waste, or scrapped and demilitarized in coordination with the Defense Logistics Agency (DLA) Disposition Services.

The portion sent back to the continental United States (CONUS) was where the Army really made back its money. Since volume did not necessarily equate to dollars, it made economic sense to sort through the materiel in Afghanistan before blindly shipping it home.

The cost to ship a 20-foot container back to CONUS is more than $20,000. It would be incredibly wasteful to ship containers full of scrap metal, trash, and obsolete military and commercial equipment that could have been disposed of in theater. That is why the CMRE was needed.

RSYS AND FRES

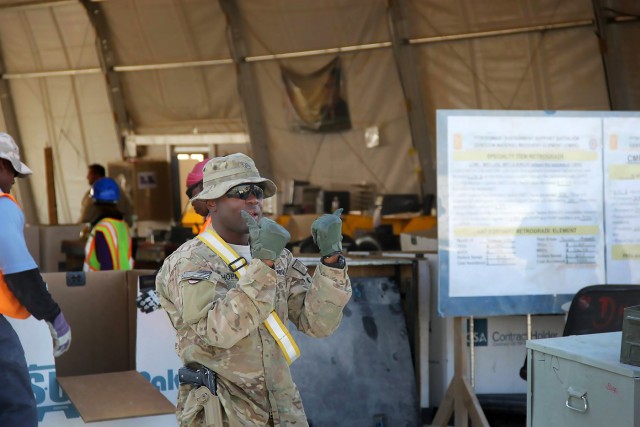

The retrograde sort yards (RSYs) were the heart of the CMRE. The RSYs were located strategically at Kandahar Airfield, Bagram Airfield, and Camp John Pratt. Feeding into the RSYs were the forward retrograde elements (FREs), which were located at Forward Operating Base (FOB) Shank, FOB Pasab, FOB Walton, and Shindand Airbase.

Designed based on FOBs in Afghanistan, the RSYs were the major hubs and the FREs were the smaller ends of the spokes. The FREs captured materiel as far forward on the battlefield as possible. The concept was to capture the scrap and other obsolete materiel forward and avoid paying intratheater movement costs from the FREs to the RSYs.

By disposing of materiel at the FREs, the Army saved approximately $2,000 per 20-foot container in transportation costs from the FRE to the RSY. If it did not make sense to ship scrap metal home, it certainly did not make sense to ship it from Shindand to Kandahar Airfield. It was easier to sell the scrap and dispose of other unwanted materiel directly at the FRE.

The FREs were also important in sending the potentially recoverable materiel back to the bigger RSYs, where they could be efficiently identified, processed, and shipped back to CONUS. The RSYs received a filtered wave of materiel from all of the outlying FREs around the hub. They also received an unfiltered mountain of equipment from units as they left the central hubs.

An RSY would then apply its filter in sorting through the equipment coming through the yard. Obsolete military equipment was sent for demilitarization through DLA Disposition Services. Commercial equipment that could not be put back into the supply system was ultimately scrapped through DLA Disposition Services as well.

The hidden gold, often buried in the obsolete equipment, was the class IX (repair parts). Over the past decade, component items would get separated from their main systems and accountability would be lost.

The process established through the RSYs allowed units to bring excess found-on-installation class IX to the yard and drop it off. This gave the units a responsible way to reduce their footprint while allowing a quick and efficient way to process the items. Items could then be returned to the Army supply system, where they regained visibility through the network of Army supply depots.

SARSS

The brain behind the processing was the Standard Army Retail Supply System (SARSS). SARSS processes class IX parts and keeps track of them as they flow from the depots to the supply support activities (SSAs) and ultimately to the units.

SARSS is a live system that receives daily updates. It keeps track of the dollar value of individual items, who is ordering them, and where in the world they need to go based on their priority and condition. Type into the system an item's national stock number (NSN) and its condition code, and SARSS will give you the dollar value and the disposition of where the item needs to be sent.

In the CMRE's case, most of the items being processed from the RSYs were going to either Sierra Army Depot in California, Tobyhanna Army Depot in Pennsylvania, or Kuwait. SARSS was smart enough to reroute items directly if a unit had made a request through its local SSA. The Kandahar Airfield, Camp John Pratt, and Bagram Airfield RSYs were equipped to route processed parts directly to the local SSA if a unit made the request.

For example, imagine that a unit requests a new transmission for its mine-resistant ambush-protected vehicle that broke down in theater. If a found-on-installation transmission were processed at an RSY, SARSS would print out a materiel release order to send the transmission to the requesting SSA. The RSYs would then quickly ship the item via strategic air, or truck if it was on the local FOB, and deliver it to the SSA where the requesting unit would pick it up. This process allowed for a much quicker turnaround time and allowed for the utilization of items that had fallen off the radar.

PARTNERSHIP WITH LCMCs

The RSYs provided a central location to send excess equipment. With the RSYs in place, the next question was how to identify all of the items. Not every item had an NSN. There were thousands of different pieces of equipment, some of them for obsolete military systems.

Subject matter experts (SMEs) were needed to help sort these items. So, the Army Materiel Command sent some of their SMEs to help. Each Life Cycle Management Command (LCMC) oversaw its own portion of Army property. The Aviation and Missile LCMC was responsible for aviation parts, missiles, and unmanned aerial vehicles, and the Communications-Electronics Command was responsible for a variety of electronic equipment. The TACOM LCMC was responsible for vehicles and weapon systems.

The SMEs from the LCMCs worked alongside the Soldiers and helped them identify valuable parts that might otherwise have slipped through the system. This partnership was an efficient way to retain as much high-value materiel as possible while retaining the velocity needed to complete the retrograde.

THE RPAT YARD

Another key partnership was between the RSY and the redistribution property assistance team (RPAT). The RPAT processed all of the major end items leaving theater, including a variety of weapon systems, generators, and other miscellaneous equipment.

However, the biggest thing the RPAT handled by volume was vehicles. The RPAT yard cleaned, inspected, and shipped more than 10,000 vehicles back to CONUS. Through a constant daily relationship, the RSYs redirected billions of dollars' worth of equipment to the RPAT yards to be returned to the United States.

SUCCESSES AND LESSONS LEARNED

During its mission, the CMRE was incredibly successful. Between December 2011 and December 2014, the RSYs processed more than 25,000 TEUs of equipment and produced more than 960,000 materiel release orders in SARSS. Of the 25,000 TEUs processed, 2,700 were shipped back home with $1.2 billion worth of equipment inside.

With the assistance of the LCMC SMEs, 4,400 TEUs of equipment were redistributed across theater. The equipment was accounted for and placed directly with units in country that needed it. TEUs that were not retrograded or redistributed were sold as scrap in Afghanistan.

Even with all of the success, there are still ways to improve the retrograde process. It may be some time before the United States has another large-scale war, but it makes sense for logisticians to prepare for the future.

Logisticians should ask these key questions: Is there a way to retrograde faster if necessary? If so, at what cost? The velocity of retrograde operations may be increased, but at what cost? Perhaps we could reduce our footprint more quickly, but it might mean destroying valuable equipment that could have been recaptured. With excess speed comes mistakes and waste. Logisticians and planners must balance velocity with responsibility when planning future operations.

Another problem in the recovery efforts was capturing commercial equipment. In the rush to meet the needs of Soldiers in the early parts of the war, the military used commercial equipment to fill requests that could not be met by the Army supply system. Many of these items were never standardized and had no NSNs. Thus, there was no standardized way to capture these items and return them to the United States.

Over the years, massive amounts of unused or serviceable commercial equipment accumulated in theater. In the future, we need to consider how to balance the needs of our troops on the battlefield with the need to retain accountability of and responsibility for equipment.

The reduction of the U.S. military footprint in Afghanistan has been one of the most massive logistics feats accomplished in the modern military world. Hopefully the successes and lessons learned from this mission will be used to shape even more efficient and impressive logistics operations.

_____________________________________________________________________________________________________

1st Lt. Petar Mostarac is the brigade plans officer for the 369th Sustainment Brigade. He has a bachelor's degree in business administration from Fordham University. He is a graduate of the Leader Development and Assessment Course and the Basic Officer Leader Course.

_____________________________________________________________________________________________________

This article was published in the March-April 2015 issue of Army Sustainment magazine.

Related Links:

Browse March-April 2015 Magazine

Army Sustainment Magazine Archives

Social Sharing