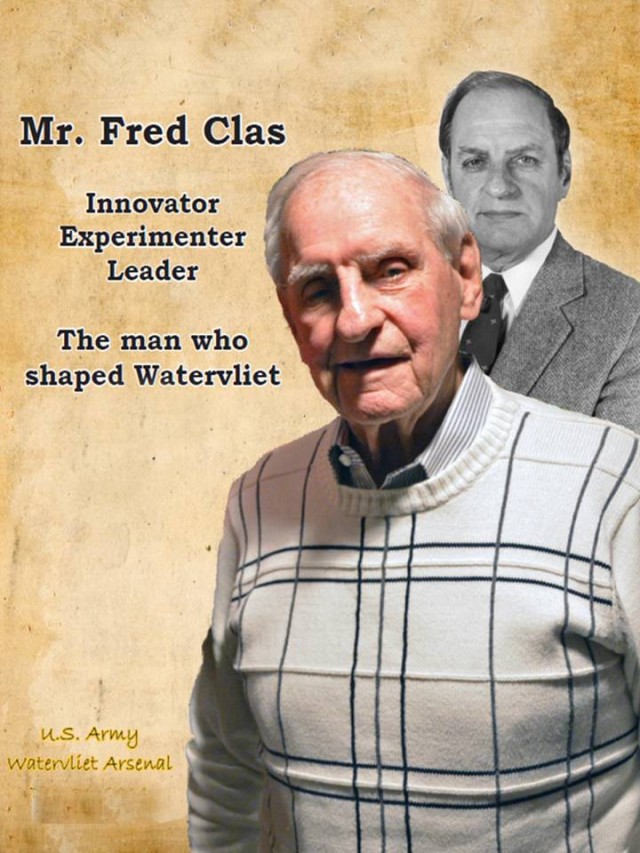

WATERVLIET ARSENAL, N.Y. (Jan. 14, 2015) -- When Fred Clas left his home on a warm summer's day and walked through the historic Watervliet Arsenal gates en route to his first day of work, little did he know then that it would take three major wars and nearly 100,000 working hours before he would depart the arsenal as one of the most revered and accomplished leaders in the history of the arsenal and the Army's Ordnance Corps.

Clas was 18 years old when he joined the arsenal apprenticeship program in 1940. By then, Nazi Germany had invaded Poland, Norway, and Denmark, as well as faced the United Kingdom in the air Battle of Britain. But even with the conflict in Europe and the rising militarization of the Pacific by the Japanese, Class did not know then that his career and life would soon be shaped by what would become World War II.

Nevertheless, his escapades on his first day of work almost did him in before he had a chance to learn anything about machining.

His first task as an apprentice was to clean windows in one of the manufacturing buildings. With Clas was a fellow apprentice by the name of Ray Farmer. After he and Farmer had put the cleaner on the windows, they sat back on the second-floor ledge and talked about their future at the arsenal.

About 30 minutes after they started, a funny looking gentleman in horse riding clothes showed up and asked them what they were doing joking around while everyone else was working. Clas said there may have been a few expletives in the gentlemen's question to him and Farmer.

Farmer must have thought the guy was not part of the arsenal because of his dress and responded with a few cusswords of his own. They would soon find out that the gentleman in the weird-looking clothes was the arsenal commander, Col. A.G. Gillespie, who soon would become a brigadier general. In 1940, the arsenal still used horses in its operations.

Clas said that he thought his career was over before lunch. Such was Clas' introduction to an Army-owned and operated manufacturing plant.

When Clas started working in 1940, his plan was to stay one year at the arsenal and then attend college at the Rensselaer Polytechnic Institute in Troy, N.Y. But when the United States entered into World War II, Clas said the President established a directive that in essence locked him into employment at the arsenal for the duration of the war.

But war has strange consequences not only for Soldiers, but also for those who support the troops. Clas thrived in the arsenal environment where working overtime was a seven-day-a-week proposition. After all, Clas grew up during the Great Depression when hard work came early in life.

When Clas was nine-years-old, his dad told him and his older brother that they would need to get a job to help out the family. They didn't hesitate. Both started delivering newspapers.

Their day began at 5 a.m. and they worked seven days a week, regardless the weather. They kept this schedule for the next nine years, walking the 6.4 mile route each day all for one penny per paper.

When Clas turned 18, his family car broke down and couldn't be repaired. So, he and his brother took money from the paper route that they had saved over the last nine years and bought the family a new car. He said he never thought twice about not using the money on himself.

This grounding, a sense of hard work and family, would be the essence of Clas' character for next forty-five years at the arsenal.

Now, at age 92, Clas speaks lovingly of what he calls "his arsenal." In his "man cave" located in the basement of his house are volumes of arsenal history, from newspaper clippings to the diary he kept while he was in the apprentice program.

His eyes light up when he talks about the great commanders, mentors, machinists, and employees that he had the pleasure to serve with. But when he talks about his wartime years in the apprentice program, a special glow comes over him as he explains in great detail some of the best years of his life.

According to Clas, machinists during the Great Depression were forced into mobility as they had to travel from manufacturing center to manufacturing center to find work. Very few manufacturing plants were able to keep a steady production line going and most went out of business. Because of this mobility, when the arsenal advertised for the apprentice program, many of those who were selected were journeyman machinists who had been traveling the country for years seeking long-term employment.

"Because of the Depression, there were more than 5,000 men who applied for the apprentice program in 1940," Clas said. "This great pool of talent allowed the arsenal to select some of the greatest machinists that I have ever served with."

Clas' machining days were almost derailed when in 1943 he enlisted in the Navy. Two of his brothers had just joined the Navy and he didn't want to be left out. But after 19 days of training, somehow the arsenal leadership was able to get him discharged from the Navy and thrown into an Army boot camp.

Not surprisingly, after Clas finished his Army basic and advance training, he was assigned to the Watervliet Arsenal.

"I went from earning $222 a month as a machinist to a private's pay of $37 a month," Clas said.

Clas did eventually deploy during the war, but it was to Egypt where he worked for the Army Corps of Engineers as a machinist.

Clas and the arsenal's Greatest Generation manufactured more than 23,000 cannons at a better than 99 percent on-time delivery rate. Those numbers would never again be equaled.

Despite such an historic production effort, when wars end so too does the requirement for a large workforce. The arsenal personnel numbers went from a high of more than 9,300 in 1942 to 940 by 1947.

Clas said that something magical happens when work goes away.

"After World War II, arsenals were being closed throughout the United States," Clas said. "We survived because we became inventors and experimenters."

As an example, Clas said he heard about private industry experimenting with a new compound called carbide. He visited several companies, learning as much as he could about this compound, and then tested the compound on equipment at the arsenal.

What Clas discovered was by using carbide on the tips of drilling and milling machine tools the material, which is tougher than steel, could reduce machining time by more than 500 percent.

When asked if he attained a patent for a product that can be found today in any hardware section of any store, he said he did not.

"I was a 25-year-old kid, what did I know about patents," Clas explained. "But as I look back on some of the manufacturing tools and techniques that I designed through the years, I didn't do it for the money. I did it to make the arsenal better."

Clas explained that through invention and experimentation the arsenal became more efficient than any other arsenal, as well as became more aware of its vast capability to manufacture products that did not fall into the traditional lines of production.

"In the 1950s and 60s, we invested a lot of energy into prototype development," Clas said. "We were always on the road talking to procurement offices and to private industry asking them about some of the production challenges they had. It didn't matter what the production challenge was, we would bring that challenge back to the arsenal and see if we could manufacture it."

As an example, Clas said he found out the Army was having difficulty with a defense contractor that was providing blades for large bulldozers. He was able to get a copy of the technical data package and within two days had a quote to the Army that was $1,000 per blade cheaper than what the Army was currently paying. The Army gave the arsenal a contract for 500 blades.

Other examples Clas provided were casings for the Air Force's Nike Hercules surface-to-air missile system and Scissor Bridges for the Army.

Clas' passion for the arsenal and his sense of duty to make the arsenal better each day did not go unnoticed.

He said that every year after the apprentice program he received a promotion, and by his early 30s he was the deputy director of arsenal operations. In 1963 he became the director of operations, a position he held until he retired in 1985.

During his career, he had seen the arsenal move from guns for battleships to nuclear-capable weapons for the Cold War to self-propelled artillery for Vietnam to the most advance tank system in the world, the Abrams Tank.

But beyond all the greatness that Clas helped bring to Watervliet, he remains a humble man. Clas said he was offered numerous job opportunities from private industry, some of which would have more than tripled his pay. He turned them all down.

"I had a great family life growing up," Clas said. "We would go fishing, hunting, and even through some pretty tough times we remained very close."

"To me, the arsenal is like my family," Clas said. "It took care of me when I needed support, offered me opportunities way beyond my dreams, and even through some very tough times, we remained close. And so, how could I ever think about leaving the arsenal?"

Clas said his goal throughout his 45 years of service was to maintain the arsenal's capability and it personnel numbers during periods of peace.

"It is what we did between wars that mattered most to the workforce," Clas said. "I felt such a fondness for the arsenal worker that it pained me when we would tell our workers thanks for your wartime service but you are no longer needed. That drove me to work harder to find new work."

Before Clas became part of the arsenal's Greatest Generation, he was simply a young man who struggled to survive the daily challenges of something called the Great Depression. But something changed in that young man when in 1940 he put his hands on an arsenal production machine for the first time; it was as if the arsenal's lifeblood, its history, its pride, flowed from cold steel and into his palms.

When one shakes Clas' hand today and looks into his eyes, something becomes changed in them, too. There is an immediate sense of reverence and respect for this humble man who simply wanted nothing more in life than to make the arsenal better. He did!

__________

Class is a 1988 Inductee into the U.S. Army Ordnance Hall of Fame

Mr. Frederick J. Clas was born in Albany, New York in 1922 and began his career as an 18-year old machinist at Watervliet Arsenal in 1940.

He served for two years as an Army enlisted man during World War II and remained at Watervliet for more than four decades until his retirement in 1985.

For the final 21 years of his tenure there, he was Director of Arsenal Operations. Among his many accomplishments were the successful introduction of carbide into machine cutting tools, which increased their productivity 500 to 1000 percent; the use of high speed photography in the study of chip formation; the installation of flexible manufacturing systems, presently the largest in the country; and the establishment of performance standards more stringent than most in private industry.

His efforts resulted in a greater than 99 percent completion on scheduled production rate during World War II and a better than 98 percent rate during the Vietnam Conflict. Mr. Clas served under 18 commanding officers during his tenure as Director of Arsenal Operations. The smooth transition from each of these to the next could not have been accomplished without his experience and expertise.

The dedication of most of his professional career to the able management of cannon production has been a major service to the Ordnance Corps and to the United States Army.

Related Links:

Watervliet Arsenal Flickr Page

Watervliet Arsenal Slideshare Page

Watervliet Arsenal YouTube Page

Social Sharing