McALESTER, Okla. (Oct. 29, 2014) -- Work to extend the service life of Stinger Block I missiles and expand its capabilities on the battlefield began at McAlester Army Ammunition Plant, Monday, said officials here.

The nearly $11 million project for Cruise Missile Defense Systems from Redstone Arsenal, Alabama, calls for workers to replace aging components that are susceptible to degradation, said Tommy Hendrix, industrial specialist, Precision Munitions Division, Ammunition Operations Directorate at McAlester Army Ammunition Plant, or MCAAP.

Billed as the Stinger Service Life Extension Program, the work will extend the service life for 2,005 missiles in the Defense Department inventory, for another 10 years. MCAAP will upgrade 850 Stingers for the Army, and 1,155 for the Marine Corps.

In addition to replacing components to extend the service life, MCAAP will also install a warhead section equipped with a Target Detection Device, commonly known as a proximity fuze. The Target Detection Device provides increased effectiveness against unmanned aerial system threats.

Work is expected to continue through 2016, Hendrix said.

During the preparatory stage, MCAAP worked with the Cruise Missile Defense Systems to refine the scope of work, design the production layout to maximize the workflow, determine workforce requirements, ensure subcontracts are in place with vendors who will provide critical components and develop the necessary classification to transport the munitions.

The project calls for MCAAP to disassemble the aging FIM-92E Stinger and install a new flight motor, proximity fuze warhead section, gas generator cartridge, o-rings and desiccant cartridge.

The upgraded Stinger -- also a Block I -- will be redesignated as the FIM-92J.

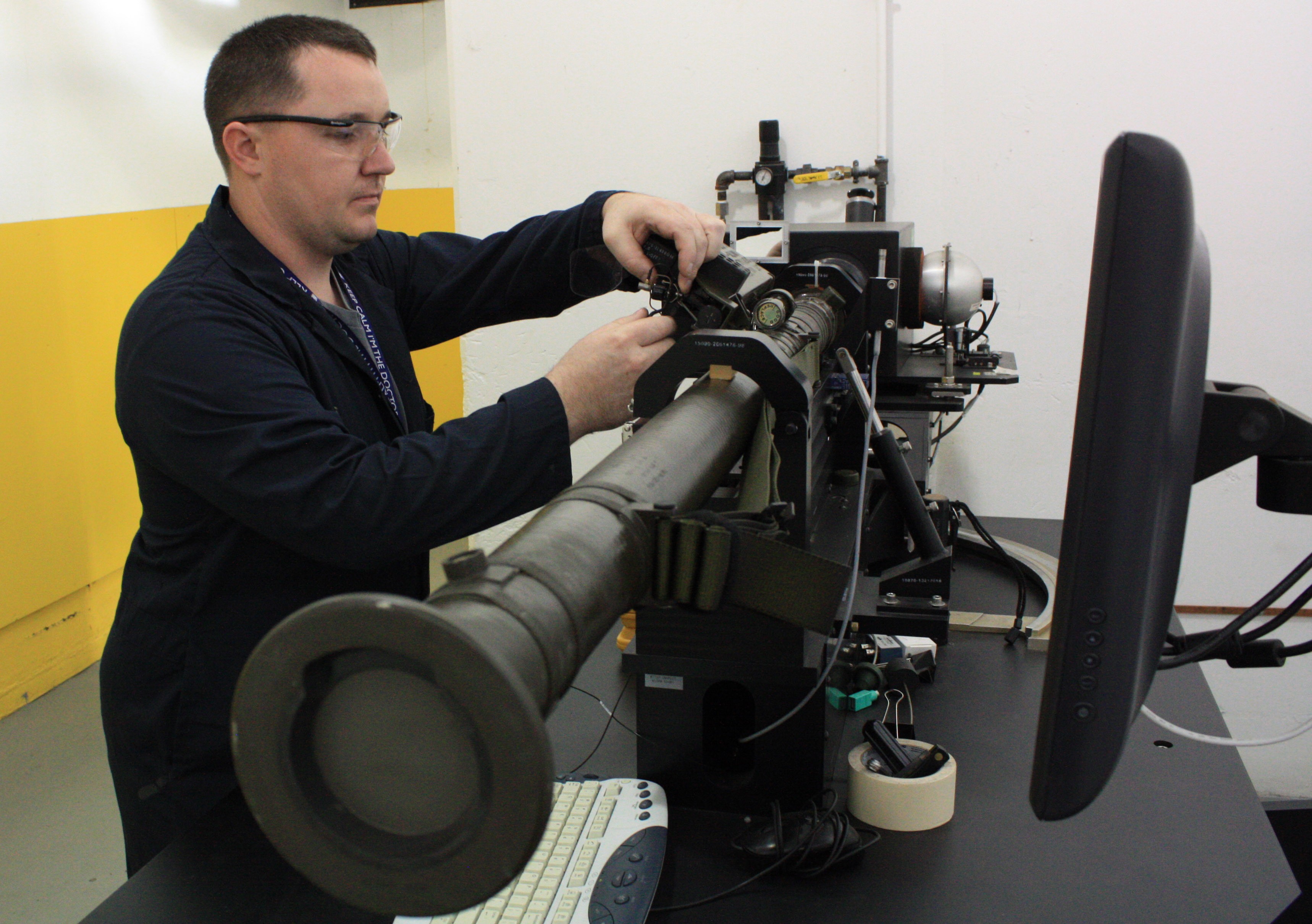

As part of the project, MCAAP workers are required to examine each Stinger missile on the Guided Missile Intercept Aerial (GMIA) test equipment before disassembly. Components that successfully pass the examination -- such as the guidance section, launch motor, tail fin, launch tube and container -- will be used in the upgrade along with the new parts.

"We worked to incorporate Lean practices into the project before work began," said Kurtis Lund, management analyst, Continuous Improvement Division at MCAAP. "The intent was to error-proof the work by taking steps to produce an efficient production flow."

MCAAP will demilitarize the components not used in the upgrade or will be retained for future use.

Once the assembly is complete, each missile will undergo final Guided Missile Intercept Aerial inspection, continuity and leak testing before being repackaged for delivery to the customer.

The Stinger Reprogrammable Microprocessor, or RMP, entered production in 1985, and was delivered in 1989. The Stinger RMP Block I is an upgrade to the original Stinger RMP, and was delivered between 1996 and 2005.

The Stinger is a short range fire-and-forget infrared/ultraviolet missile system that is both shoulder fired and mounted on a variety of air- and ground-based platforms. It can be used against a variety of low-flying unmanned aerial systems, cruise missiles, rotary wing or fixed wing threats.

Stinger missile testing and stockpile reliability work transferred to MCAAP in 2010, from the Red River Munitions Center, in Texarkana, Texas, which was shuttered by the 2005 Base Realignment and Closure Act.

"Our precision munitions capabilities are becoming well-known to our customers and potential customers," Hendrix said. "We receive requests for estimates weekly -- whether it's for maintenance or demilitarization. We believe this aspect of our business will continue to grow."

-----

McAlester Army Ammunition Plant is the Department of Defense's premier bomb- and warhead-loading facility. It is one of 14 installations of the Joint Munitions Command, and one of 23 organic industrial bases under the U.S. Army Materiel Command, which include arsenals, depots and ammunition plants. MCAAP is vital to ammunition stockpile management and delivery to the joint warfighter for training and combat operations.

Social Sharing