TOBYHANNA ARMY DEPOT, Pa. -- A vast array of unique test fixtures at the Packaging Applications Testing Facility here gives one-of-a-kind capabilities within the Department of Defense.

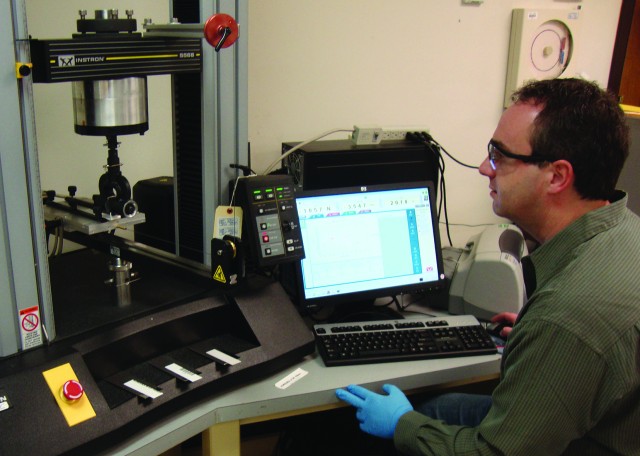

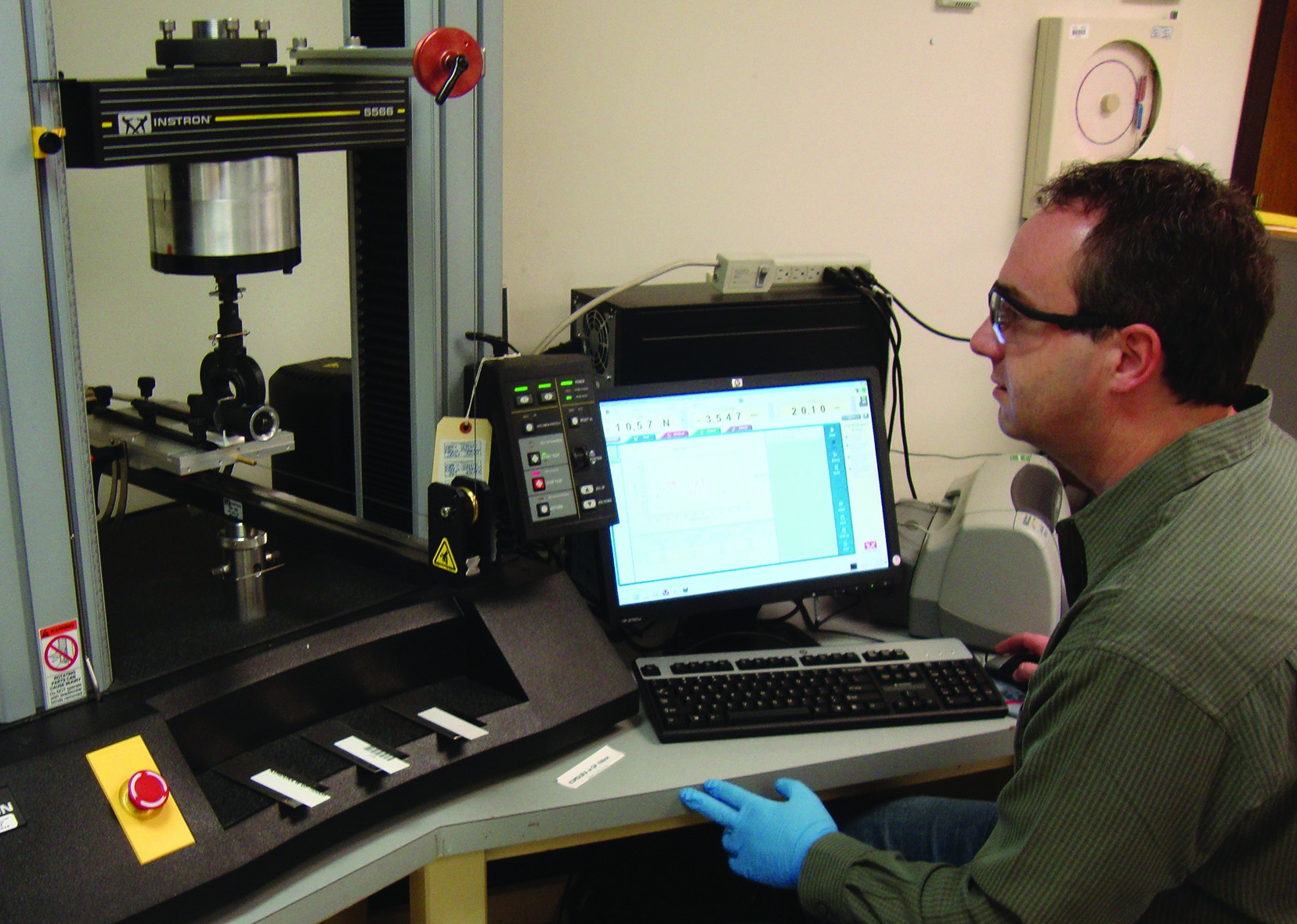

The facility is part of the Logistics Support Activity's Packaging, Storage and Containerization Center, a tenant activity at Tobyhanna Army Depot. Engineers and technicians use the test equipment to perform specialized testing of packaging materials.

Case-in-point is the test facility's tension and compression test machines. Besides the normal pulling and crushing applications which these machines perform in most test facilities, PSCC has invested in test fixtures that provide singular testing capabilities.

"One of these fixtures consists of a specialized inflatable bag used to test non-metal pallets," said General Engineer Patty Curran. "When used in conjunction with PSCC's 30,000 pound--compression testing machine, this inflatable bag simulates uniformly distributed case goods and bag loads."

Another tension and compression test machine is equipped with a $16,000 specialized capstan grip used to determine the breaking strength and stretching ability of textile webbing, tape and braided material. This split-drum type clamping assembly determining accurate values of breaking strength and extended length without the added complication of breakage caused by improper clamping.

"We use an even-more specialized type grip to determine the breaking strength and stretching ability of pressure sensitive tape," Curran said. "This unique cylindrical grip enables the easy and efficient removal of sticky tape residue between test iterations."

The tension and compression tester located in PSCC's Standard's Lab is equipped with a specialized fixture that provides scientific results when testing the adhesive force of labels or tapes. The $8,000 variable angle peel test fixture consists of a bearing-mounted table linked to the testing machine's crosshead by a cable and pulley system. One end of the test specimen is placed on the fixture's table surface, and the other is inserted into a standard machine grip.

"As the crosshead moves in the tension direction, the cable pulls the table laterally along the rail to maintain a constant preset angle for the peel," Curran explained. "The motion of this fixture prevents any exertion of outside forces on the specimen which allows the load--weighing system to provide a direct measure of bond strength."

Editor's Note: For more information concerning PSCC's test capabilities for tension and compression machines, as well as other unique packaging materials test equipment, contact Curran at DSN 795-7756 or 570-615-7756, email patricia.a.curran6.civ@mail.mil

Social Sharing