ANNISTON ARMY DEPOT, Ala. -- Four labs located in Anniston Army Depot's Nichols Industrial Complex assist the production area to ensure equipment and vehicles overhauled or repaired here meet stringent specifications required by the U.S. military and its allies.

Three of the labs -- the Materials Lab, Chemical Lab and Oil Analysis Lab -- were consolidated under the Directorate of Risk Management in February. A fourth, the Environmental Lab, was already part of DRK.

"Each of the labs has a separate, primary function, but they all have the same mission: to ensure the depot puts out a quality product for the warfighter," said Randy Bright, chief of DRK's Environmental Compliance Division. "Through the tests they run, we gain important feedback on the quality of our products and it provides the depot with insight to adjust processes as needed, making them run more efficiently."

MATERIALS LAB:

The Materials Lab supports a wide variety of testing, all done with the goal of improving the depot's production processes and products to ensure equipment received by the warfighters meets standards.

The lab is capable of testing the properties of metal samples for:

• Tensile strength

• Hardness

• Impact resistance

• Abrasion resistance

• Tension and compression (springs)

• Hydrogen embrittlement

• Composition

• Surface roughness

Additionally, portable equipment enables the lab technicians to test metal hardness and composition on-site for pieces of equipment which, due to size or other factors, cannot be brought to the lab.

"It is not only what we are capable of doing, but also what we should be doing to ensure we are sending out quality parts and receiving conforming parts," said Phillip Coleman, a materials engineering technician.

Coupon testing in the lab supports all of the depot's plating operations.

Coupons, which are small, thin pieces of metal, go through the same processes (plating, cleaning, etc) as the part. Then, rather than taking the entire part for testing, the coupon is tested to ensure the coating placed on the metal meets specifications and adheres as it should. Since it has gone through the same processes and started as the same type of metal, a correlation can be established that the part also meets these same specifications.

"We evaluate the coating for thickness, adhesion, hardness and, perform load testing for hydrogen embrittlement," said Doug Swain, a materials engineer.

The employees in the lab see themselves and their equipment as a toolbox for the depot, capable of being used to ensure the equipment Soldiers receive meets requirements.

"By working through problems in processes, the depot can improve the quality. The ultimate goal of testing is to improve the quality of products produced at Anniston Army Depot," said Swain.

Some of those problems come to the lab in the form of product failures.

"Failure analysis is an investigation of a failure. It is important when we look at a failure to look at the complete picture. We don't just investigate the parts, we look at all the processes and circumstances leading up to the failure," said Swain.

Failure analysis is performed for equipment failures and in support of the Safety Office following accidents.

The lab will soon receive a scanning electron microscope, which will assist in evaluation of hydrogen embrittlement and failure analysis. Currently, this type of testing is contracted out.

The lab also supports non-destructive testing.

Swain is certified by the American Society for Nondestructive Testing as a Level III, MT, PT, meaning he is qualified to train those who perform non-destructive testing in the shops and write testing procedures.

CHEMICAL LAB

The depot uses a variety of chemical vats for a range of purposes -- from coating part of a combat vehicle to cleaning the grease from an engine component.

The Chemical Lab's primary job is to determine the chemical composition of all plating and coating tanks, maintain the tanks to military and industry specifications and ensure the ratio of chemicals mixed in the vats are within the correct range.

Each chemical tank on the installation operates best -- coating or cleaning as needed -- within set parameters. When the vat is within range, its chemical makeup can perform the task required at the temperature specified for the operation and the time prescribed for parts to be immersed.

After testing is done on the composition of each vat, lab personnel can tell shop employees what chemicals should be added, and in what quantity, to get the composition close to the center of that range.

"We try to keep each vat operating at the midpoint, but we do have a range to work in," said Chemist Stanley Wilson.

As each vat is tested, the lab looks at more than just the chemical makeup of its contents. If the quality is good and parts are passing conformance testing, the chemicals may not need to be altered.

For that determination, Wilson relies on coupon testing performed in the Materials Lab as well as tests he performs on coupons provided by the maintenance shops.

Corrosion resistance testing, which is performed by the lab on zinc-plated items, phosphate-coated items and parts receiving aluminum chromate, tests each coating's ability to withstand set conditions in a salt spray chamber.

The salt spray chamber delivers a uniform mist over the coupons at a set pressure to accelerate conditions which create rust or corrosion.

"Each process has a different set time of exposure in the salt spray chamber," said Wilson. "We aren't testing to see how long the part can go until it rusts, but we are checking to see if it meets specifications."

Other activities performed by the Chemical Lab include:

• Aluminum abrasion resistance testing for anodized aluminum

• Updating shelf-life labels for chemicals which have gone past their due date based on recommendations from manufacturers as to their viability and testing performed in the lab or at an independent lab

• Ordering of industrial chemicals and proprietary chemicals which the installation has determined will be ordered in a certain way from a specific manufacturer because that chemical achieved the desired results and ordering from another manufacturer would mean testing to ensure the parts meet specifications.

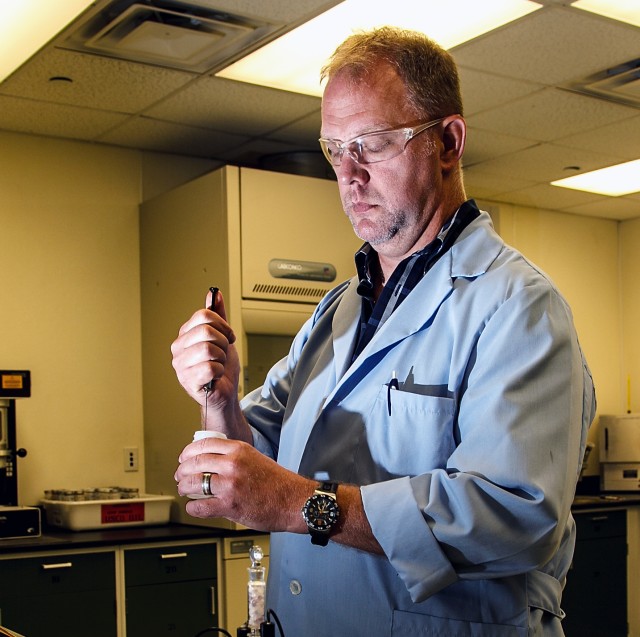

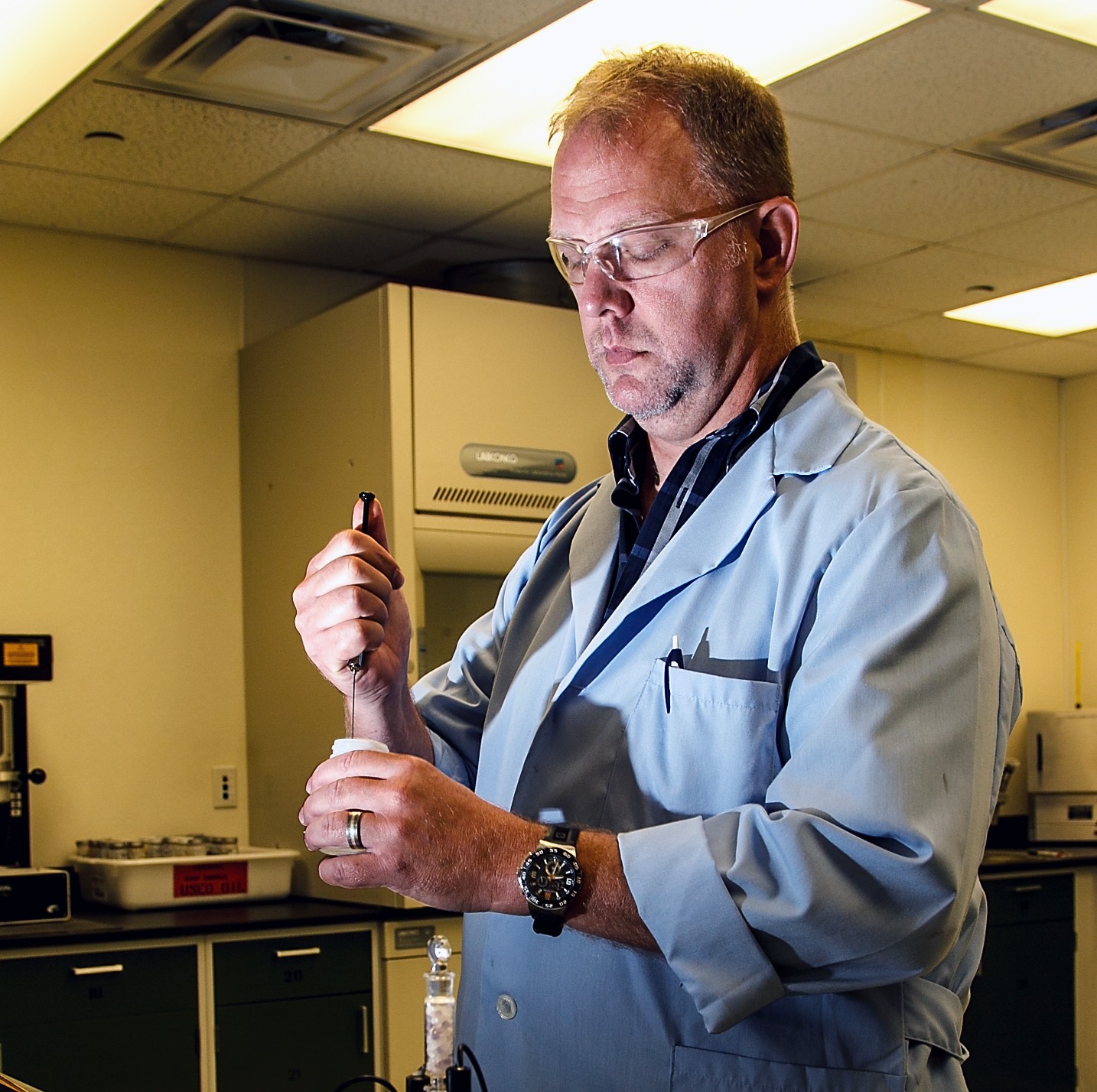

OIL ANALYSIS LAB

The depot's Oil Analysis Lab performs analytical oil testing services for the production and support equipment shops located on depot.

Testing is performed based upon the Army's Oil Analysis Program and Depot Maintenance Work Requirements. Oil evaluators make maintenance recommendations based on data captured from used oil samples taken from components, oil-wetted systems of combat vehicles and their support equipment, which is tested and evaluated in the lab.

Support equipment tested in the lab includes test stands, dynamometers, locomotives and generators.

The Army Oil Analysis Program has three categories: aeronautical, non-air (ground equipment such as bulldozers) and quality assurance. Most of the depot's work falls in the third category.

"This analysis is beneficial for getting to problems at the earliest point," said Bobby Hunter, a physical science technician for the depot.

Engines and transmissions are often tested at various points in the assembly and testing process -- in the dynamometer test cell, at mating and when it is installed in the vehicle -- essentially anytime additional items are added to the engine, analysis must be done to ensure those additional items have not affected the engine or added contaminants to the oil.

Hydraulic systems are tested at the point of assembly, when they become a closed-loop system.

Testing is done both for the depot and for the Defense Logistics Agency. DLA requests samples of items which have been in storage to ensure they are still to specifications after sitting.

"We protect the supply system," said Hunter. "Some of the items we test are in return-to-stock programs."

Each type of tracked combat vehicle overhauled or repaired on the depot is enrolled in the program. So, testing performed on engines and other components in the vehicle are part of the oil analysis program.

This means for each sample there is a history on that type of item and a history maintained on the item itself by serial number.

Tests performed in the Oil Analysis Lab include:

• Atomic Emission Spectrometer -- tests for wear metals and additive depletion

• Fourier Transmission Infrared -- physical property test for contamination/deterioration

• Dual-Temperature Viscosity -- tests for degraded oil, fuel or water depletion and incorrect oil type

• LaserNet Fines -- fluid cleanliness and shape identifier

• Karl Fischer -- water for non-additive fluids

• Fuel Dilution Meter -- concentration of fuel in oil samples

• Ferrography System -- cause of wear metal

• Particle Counter -- fluid cleanliness

• Millipore Patch Test -- fluid cleanliness

• Crackle -- hot plate test

• Flash Point

Results from these tests are fed into a software program known as the Oil Analysis Standard Interservice System, or OASIS. Every U.S. military maintenance installation and every branch of service can feed data into the same system. So, if the same type of equipment is maintained or deployed by multiple branches of service, they are each able to use the same database and the same standards.

"When we enter a sample, it lets us know if that piece of equipment has been entered into the system before. So, it's critical for employees on the shop floor to write the information legibly and enter the correct serial number, since each component is tracked in OASIS by serial number," said Hunter.

Since each part's tests are tracked by the serial number for that part, its history can be viewed by the lab technicians.

Once data from a tested sample has been evaluated, the lab can tell the shop whether the sample is good or bad, normal or abnormal. This gives the mechanics a better picture of what is going on as they test the vehicle, engine, transmission or hydraulic system.

The oil analysis is a piece of a larger testing puzzle. It may or may not pinpoint exactly what is wrong, but, combined with other data, can tell mechanics where to look for issues.

How accurate testing is often depends on the mechanics. Sampling should always follow testing procedures for the particular piece of equipment -- dictating at what point in the testing or assembly process the sample should be taken.

"Samples are only as good as the sampling technique. They have to be taken at the prescribed time and in the correct way," said Hunter.

ENVIRONMENTAL LAB

Located at the Industrial Wastewater Treatment Plant, one of the main missions of the Environmental Lab is to process water samples for the Sewage Treatment Plant and IWTP, ensuring the plants' output meets requirements established by the Alabama Department of Environmental Management and Environmental Protection Agency.

This includes permit-required tests as well as process checks to ensure the plants are running well.

"Our main job is to support the depot mission by providing quality control testing for the shops, process checks for the treatment plants, and ensuring that the effluent wastewater from the IWTP and STP meets all regulatory requirements," said Sheila Humphrey, a depot chemist for the Environmental Lab.

Permit-required testing performed by the lab includes:

• Metals

• Total suspended solids

• E. coli

• Biochemical oxygen demand

• Hexavalent chromium

• Orthophosphate

• Oil and grease

• pH level

The lab also handles semi-annual stormwater sampling and assists the chemical lab with vat testing.

The chemical vat tests determine the volumes and types of chemicals to be added to the vats to ensure they are within the proper operating range.

Environmental Lab personnel verify the concentration of hexavalent chromium present in the chrome plating vats and test the chemical composition of solvent vats to ensure the correct ratio of chemicals is present in each vat.

"By testing the concentrations of chemicals in the vats, we're ensuring the parts processed in the vats are quality parts," said Humphrey.

When a spill occurs on depot, the lab steps up to assist -- collecting samples of the chemical involved and performing any necessary environmental tests.

They also periodically test drinking water quality in the production areas and the lab coordinates all groundwater sampling and testing on depot.

"We want to make sure the depot isn't releasing something into the water that will affect aquatic life or the water quality," said Humphrey. "The lab has the opportunity to do a variety of jobs, so we feel very fortunate to be here and we enjoy our jobs."

Social Sharing