ABERDEEN PROVING GROUND, Md. (Aug. 27, 2014) -- The U.S. Army is testing systems to improve how fuel is monitored and tracked across the battlefield, officials said.

Scott Nielsen, a project engineer with the U.S. Army Tank Automotive Research, Development and Engineering Center, said the current system for fuel accountability and visibility in a tactical environment has areas in need of improvement.

The Army stores fuel in large collapsible tanks, with capacities up to 210,000 gallons that can be connected to create a storage and distribution system point holding more than one million gallons. To determine the fuel system's volume, Soldiers use a level string and yardstick to measure the tank's height that corresponds to a strapping chart. Each height increment corresponds to a specific volume.

Collapsible tank systems, which have been used since the late 1970s, present challenges in accurately determining the volume, Nielsen said. Several factors can introduce errors: temperature variances are not accounted for, tanks may sit on uneven ground, and tanks can stretch over time. It is also more difficult to precisely measure height when the tank is at less than 20 percent capacity, because the fabric is not under normal tensile loads.

"It was always good enough for the accountability requirements that we had in the past. The efforts in Iraq and Afghanistan showed us that we needed better measurement methods," said Nielsen, who supports Product Manager Petroleum and Water Systems.

Nielsen stressed that these collapsible tanks are quickly deployable and easily transportable systems. Because they are intended for tactical environments, engineers face limitations in how they are designed, constructed and deployed.

"We want real-time accountability," Nielsen said. "How much fuel is in that system? How can we account for it more accurately when it's being transferred from that system to a unit that has just driven up with their bulk tankers? How do we account for the movement of that fuel? We need visibility of the fuel through the battlespace. Where it is going, and who needs it?"

To demonstrate improvements to the fuel-processing system, the Army partnered with the Penn State University Applied Research Laboratory in June 2013, and focused on the Fuel System Supply Point, the main hardware system used in Army tactical fuel depots.

Ed Crow, a Penn State senior research engineer, said his first goal was to understand the sources of error in fuel accountability.

"A lot of the error analysis was caused by inadvertent process error. Our approach was to look at the entire process, not necessarily any one instrument, and mitigate error," Crow said.

Penn State developed improvements to the system during the year leading up to a demonstration during a Reserve unit training exercise at Fort A.P. Hill, Virginia, in June 2014.

Crow and his colleagues initially replaced the digital electronics of commercial turbine flow meters that had already been tested and deployed in the field. They also incorporated a method to adjust the readings for differences in fuel temperature as well as equipment to collect data digitally immediately after a fuel transaction.

The smart meters automatically perform the arithmetic normally done by Soldiers, and eliminate errors from writing down numbers incorrectly. Metering fuel in and out of the system to determine quantities in the collapsible tanks was the most technically feasible solution within the team's timeframe to complete the demonstration system, Nielsen said. Metering also does not add significant equipment, training or installation time, because Soldiers already have experience with this procedure.

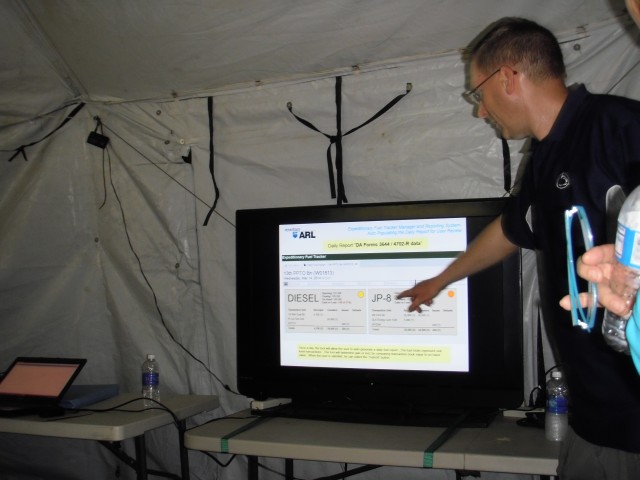

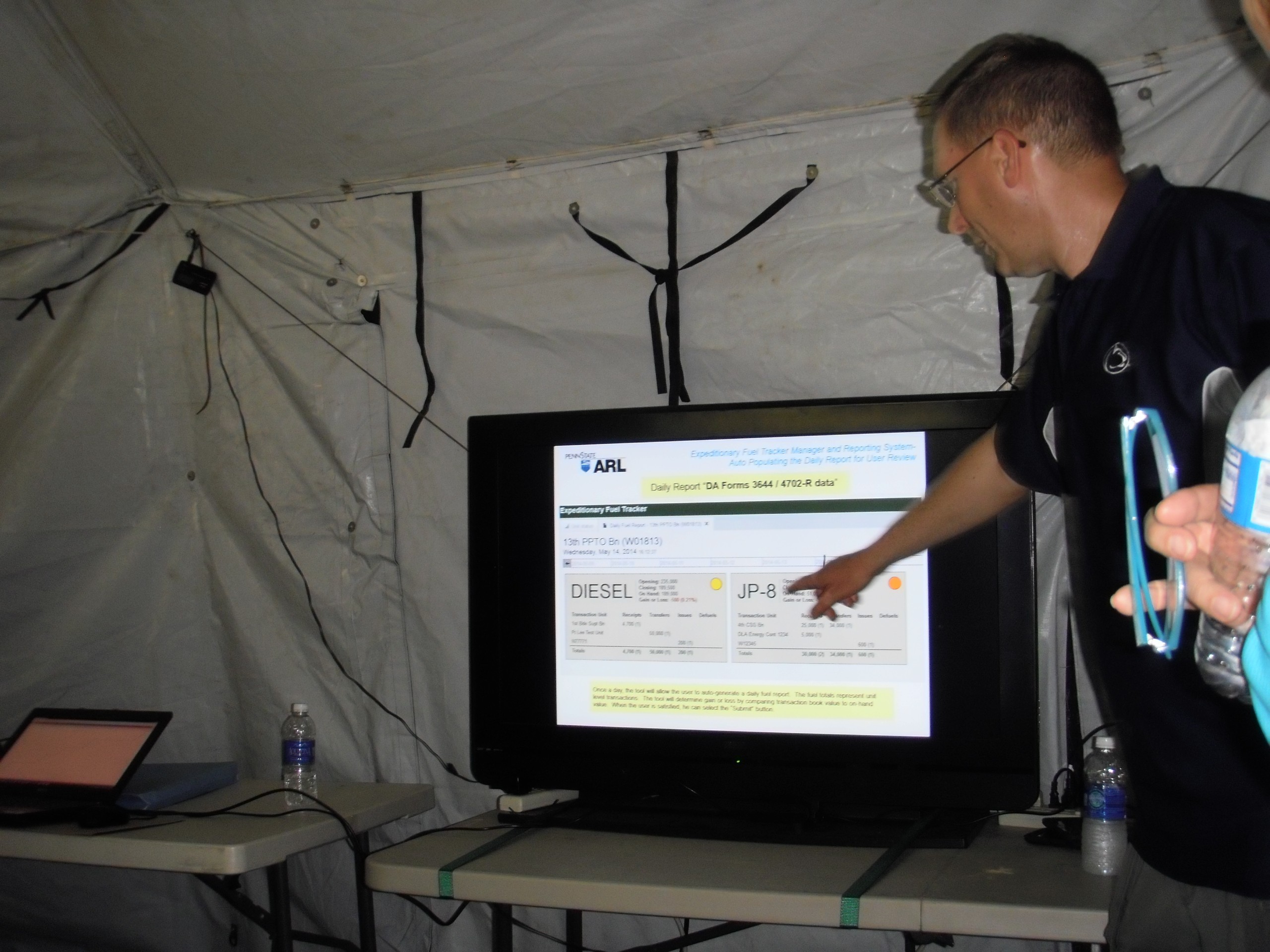

The group also incorporated handheld electronic devices that digitally capture data by taking an optical scan of the meter before and after the flow of fuel, and constitute capture of the fuel transaction. Multiple transactions are transferred wirelessly to the fuel manager's laptop, where overall fuel transactions and bulk fuel inventory are tracked and reported.

Crow said the new system detects disparities more quickly than a human does, using the current system of paper charts and inventory forms. Errors can be recognized within hours instead of days or weeks.

Improving the visibility of fuel across the battlefield was the final key piece of the overall solution, Crow said. Tankers were equipped with sensors and satellite transmitters to automatically report fuel level and location when the operator simply powers on the control panel. Mission command and bulk fuel logisticians can then view the transportation status in the area of operations.

"We're able to provide a full tactical picture of fuel movement from the source to its endpoint or interim destination," Crow said. "If you're a tactical commander and you're getting low on gas, you're worried if they're bringing gas, and how do you know that? Your comfort level is greatly increased if you can see fuel en route."

This concept was initially developed for the U.S. Marine Corps, under Office of Naval Research funding.

Nielsen and Crow said feedback from the exercise was positive. Equipping a unit with improved technology will allow Soldiers to better complete their missions and improve morale, Crow said.

"We're improving pride within a fuel unit by accurately reporting fuel accountability and visibility data," he said.

-----

The Tank Automotive Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Social Sharing