FORT LEE, Va. (June 25, 2014) -- Soldiers who have sought relief from the hot desert heat of Iraq or the mountain cold of Afghanistan, and found it in some temperature-controlled shelter, probably never stopped to ponder the working origins of their comforts.

That oversight is an accepted reality for Staff Sgt. Russell Dilka and others who are part of the Army's utilities equipment repairer community. He said those who work in the military occupational specialty of 91C do so under some measure of obscurity that comes with the mission of keeping air conditioning and heating equipment operational.

"It's one of the most overlooked MOSs in the Army," said the instructor/writer on the floor of Rozier Hall located on the Ordnance Campus, "because when you think of the military, you don't think of an air conditioning mechanic. You think of Rangers, the field artillery guys, etc. It's an image issue."

The Utilities Equipment Repairer Course falls under the Ordnance School's Tactical Support Equipment Department. Thirteen weeks in duration, it includes instruction on basic electronics, air conditioning and refrigeration systems, portable heating systems and fire extinguisher systems.

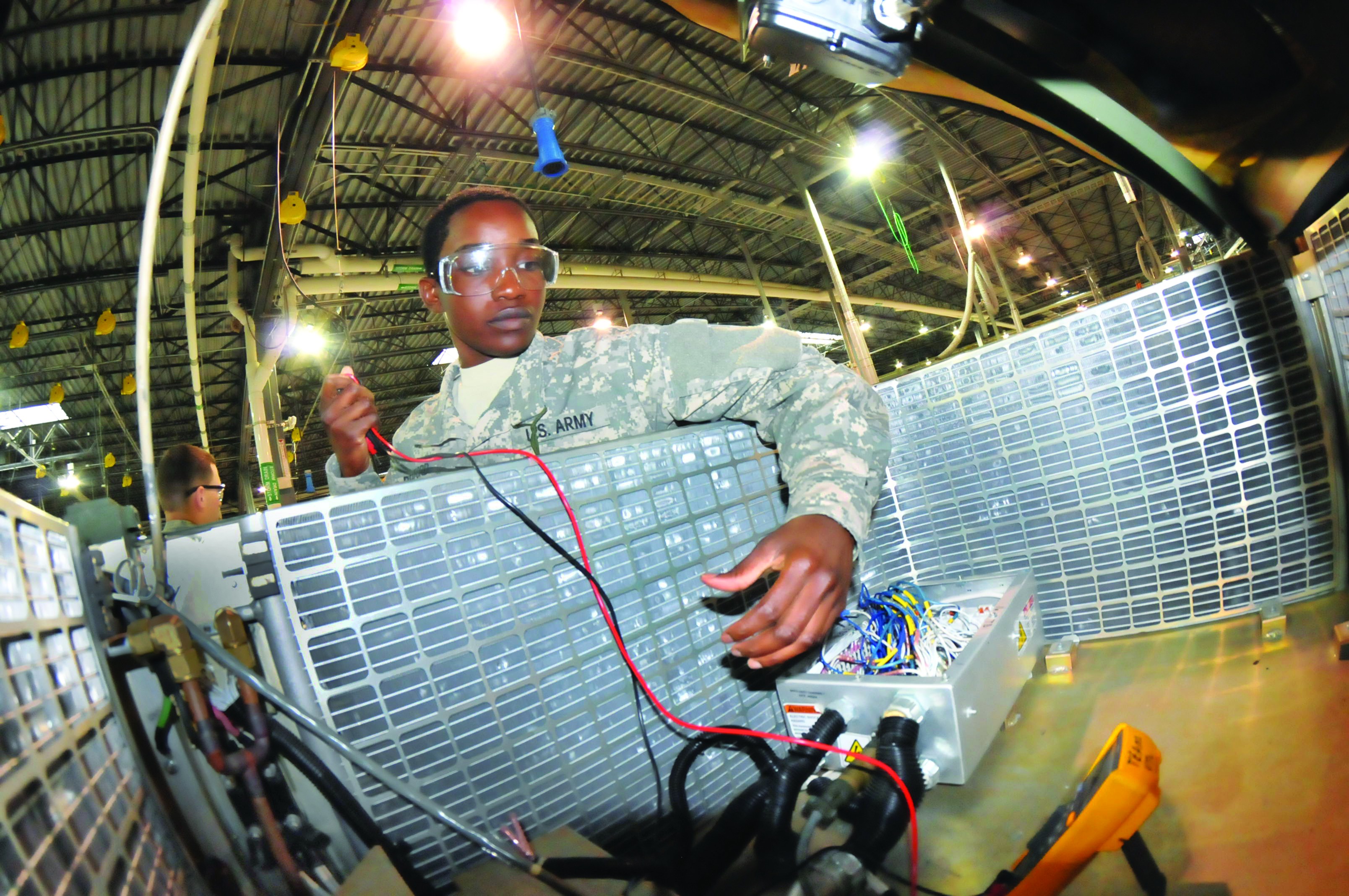

"It is a very technical and in-depth course," said Dilka, noting students are required to maintain and repair eight or nine pieces of machinery. "They put their hands on and get into each piece of equipment."

Though technical, its level of difficulty is not an obstacle for most students. The average class size is about 16 individuals who are guided by two-to-four instructors. The course produces roughly 700 graduates per year and has a 97-percent pass rate, said John D. Childers, TSED's Utilities Division course manager.

"Every now and then, we may have to restart a Soldier," he said, "meaning they may fail one module and have to be moved back to re-take it, but it is rare that we have to remove a Soldier because he or she isn't able to pass a particular test or block of instruction."

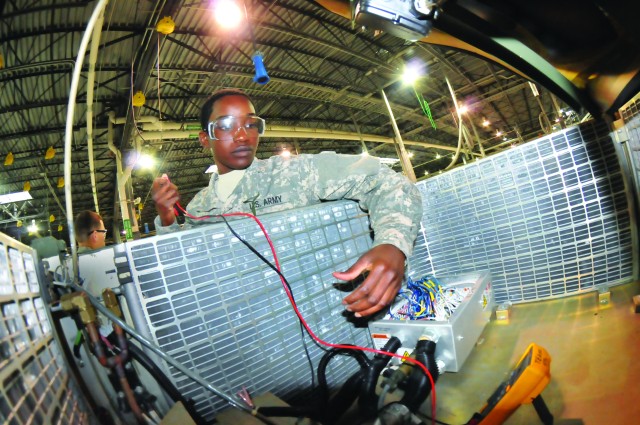

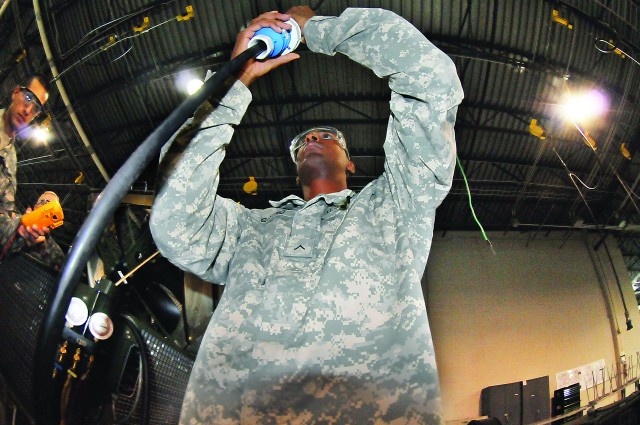

Recently, a group of students were undergoing hands-on instruction on the Improved Environmental Control Unit, a combination heater/air conditioner that is one of the latest additions to the Army's inventory. Working in tandem, they were charged with troubleshooting problems pre-set by instructors. One of them, Pvt. Alisha Beckford, described the course as challenging at the very least.

"It's pretty difficult in the beginning because it feels like so much is being crammed in such a small amount of time," said the 25-year-old Bronx, N.Y. native, who has no prior mechanical experience. "You quickly find out that the level of difficulty and the time limits actually help you better retain the information, especially since it's such a hand-on course."

Beckford's partner in the exercise, Pvt. Brian Hughes of Charlotte, N.C., said the course's fast pace and equipment diversity makes for a rather dynamic learning experience.

"You're constantly working, thinking and learning," he said. "You're not just sitting in one spot, watching things go by. There's always something changing and always something new."

The course environment sets the stage for what the students will experience in theaters of operation such as Afghanistan, where temperatures can reach 130 degrees in the summer and equipment is subjected to heavy use.

"It's a grind," Staff Sgt. Ryan Withers, a 91C instructor, said of the workload there. "Everyone knows that 91Cs really get to do their job when they are deployed."

It's not uncommon to turn over 12-14-hour days on average and sometimes 18-19-hour days when supporting the various forward operating bases, added Withers.

"You're constantly repairing equipment -- air conditioners for tents and refrigeration units for the dining facilities and air conditioners for vehicles," he said.

From the perspective of end-users, the behind-the-scenes work requirement is all immaterial. Soldiers have come to expect comfortable temperatures in which to work and rest not to mention chilled beverages at the field dining facility, said Dilka.

"Everyone wants AC," said the Soldier of 17 years. "Everyone likes ice in their Kool-Aid."

The world of utility equipment repair is not limited to Soldiers' preferences. The Army's ever-increasing use of heat-sensitive computers and its need to keep medical supplies and food at proper temperatures are both vital and essential to mission accomplishment, said Dilka.

That criticality is bolstered by the fact that students earn four certifications at graduation. The certifications are required to work with refrigerants used in air conditioning and refrigeration equipment and are only available to 91Cs and a few others with exception, said Childers.

"EPA rules require anyone working with certain types of refrigerants know all the rules and regulations regarding them," he said, "specifically, the rules not to vent them into the atmosphere because they have to be recovered."

In addition to the required certifications, students also are offered through a pilot program the opportunity to earn an Industry Competency Exam certification through North American Technician Excellence, the nation's largest non-profit certification body. Childers said he is optimistic that the certification's availability will become permanent.

"We've actually given the exam twice," said Childers, noting it is comprised of three portions. "One Soldier passed one portion the first time the exam was given and another passed one portion the second time it was given (22 Soldiers took the test). This is a difficult exam. There is only a 50-percent success rate within the industry, and that's after technicians have had one-two years of experience. Our third test is June 27, and we're hoping to have more students pass the exam."

Even without the certification, the training Soldiers receive in the course is both marketable and transferable in the heating, ventilation and air conditioning industry, said Raul Nieves, a civilian instructor and U.S. Army Reserve Soldier.

"I used to do this on the outside," he said. "I was able to find good work because of my training."

The 91C MOS is especially attractive to Guardsman and Reservists, said Dilka.

"A lot of them email later and tell me they changed their jobs once they got back home because of this training," he said.

The demand for those in the HVAC industry is backed up by hard numbers, said Childers.

"NATE has reported to us that there is a 40-50,000-personnel shortfall within the HVAC community," he said, "so this skill is in dire need out there in the civilian sector."

There is a definite need in the Army as well, and although Soldiers who possess the skills to fulfill those needs don't often receive the accolades they deserve, the knowledge that they're taking care of Soldiers is often thanks enough.

Social Sharing