COLUMBUS, Ga. (Sept. 25, 2008) - The U.S. Army Research, Development and Engineering Command participated in the 2008 Infantry Warfighter Conference Sept. 16 to 17 in Columbus, Ga. Six of nine RDECOM laboratories and technology centers showcased technologies, demonstrating the innovations the Army is working toward for the Warfighter.

This year's theme, "The Infantry: Heart of the Army in the Contemporary Operational Environment," provided opportunities for Soldiers to discuss recent transitions in the Infantry operations environment and how to best train American Forces.

RDECOM elements present included: Army Research Laboratory; Communications-Electronics Research, Development and Engineering Center; Edgewood Chemical Biological Center; Natick Soldier Research, Development and Engineering Center; Army Simulation Training and Technology Center; and the Tank-Automotive Research, Development and Engineering Center.

ARL showcased its Flexible Display technology from the Flexible Display Center in Tempe, Ariz. The center has 21 industry partners for efforts in the maturation of flexible displays.

"Flexible displays are really the next revolution in warrior display technology," said Eric Forsythe, ARL team leader and associate PM for Flexible Display Center technology. "They offer the Warfighter and the commercial sector technologies that are inherently rugged."

Contributing to Future Combat Systems and Army Transformation, the center aims to replace glass-based display screens in existing Soldier equipment with light-weight, rugged flexible display screens that use less power. This technology will help increase Soldier efficiency and reduce the amount of weight the dismounted Warfighter carries.

ARL's Survivability, Lethality and Enabling Materials research project demonstrations address vehicle armor research, transparent armor developments, smart munitions advancements and lightweight protection for the Warfighters. Smart munitions technology was displayed, where Soldiers could learn more about the efforts in precision-guided munitions. Potentially, a Soldier could alter the course of a bullet after it has been fired to ensure greater precision when engaging a target.

"It is really important in today's urban environment in Warfighting operations to minimize collateral damage," said Steve Taulbee, ARL engineer with the Weapons and Materials Research Directorate. He said that the Smart munitions could provide course correction and precision engagement of targets from various ranges.

CERDEC demonstrated the increased power capabilities for the Warfighter on the move. CERDEC displayed its various power sources. Portable power continues to be a daily challenge for the dismounted Warfighter.

The Command and Control Army Power Division, part of CERDEC, works steadily to improve portable and mobile power resources to extend mission times, reduce portable power source weight and quantities to decrease total logistics carried by the Warfighter on a mission.

One Soldier attending the Basic Officer's Leadership Course at Fort Benning, Ga., was particularly interested in Soldier power sources.

"I wanted to see the versions and improvements they've [the Army] made in the technologies and how it will affect us [Soldiers] moving forward," said 2nd Lt. Jason McKnight, 1/11th Delta Company and conference attendee. He said his unit is using the older batteries, but was happy to learn that the Army is working to provide something better.

ECBC supports the Surrogate Buffalo Training program by building mock Buffalo vehicles for training. A Buffalo is a heavily armored vehicle with a long hydraulic arm that can be used to check for roadside bombs during convoy operations and allows Soldiers to inspect suspected objects from a safe distance. ECBC builds two surrogates every 45 days that are designated for points all over the U.S., and abroad according to Robert Pazda, team leader for the Electronic Design and Integration Team of Advanced Design and Manufacturing at ECBC.

"The surrogate allows Soldiers to get acquainted with the equipment they will have to use in theatre before they arrive," said Pazda. He said that after Soldiers get finished using the trainer, they can enter theatre even more prepared and knowledgeable about the Buffalo equipment and controls, which allows more attention to the overall mission.

NSRDEC is developing software applications to be compatible with the Future Warrior Technology Integration system.

"We're trying to look at new technologies that will make the dismounted Soldier an integrated hub to either push or pull data from," said Dutch DeGay, NSRDEC Technology, Systems and Program Integration Directorate. "We've identified new and emerging technologies that we can put in a laboratory environment to benefit Soldier training on equipment." With this software technology network integration will be enhanced for current and future platforms. Soldiers will potentially be able to communicate with personnel in other vehicles such as humvees and helicopters or even unmanned aerial and ground vehicles when this software matures.

STTC exhibited the Soldier Training Enhancement Package. This mission planning and rehearsal system will work with the Future Warrior Integration Technology to enable Future Warrior leaders to create and disseminate a mission plans and also allow Soldier to rehearse a mission virtually before entering actual combat.

"The software could work for the platoon leader or squad leader in a mission planning capacity, or for the Soldier who will execute the plans with its mission rehearsal capability," said Tim Roberts, simulation and technology manager for Dismounted Soldier Simulations. With this software, each Soldier can perform mission rehearsals, in a virtual environment, based on the gear he will wear in battle. STEP also shows future trends and will better prepare Soldiers for their missions.

TARDEC showcased its award winning HEAT and SPARK technology, which was recognized as one of the 2007 Army's Greatest Inventions. HEAT, or the Humvee Egress Assistance Trainer, trains Soldiers how to react in vehicle rollover situations. This helps Soldiers overcome the natural fear and disorientation associated with this type of incident. The Improvised Explosive Device Mine Roller Self Protective Adaptive Roller, or SPARK, provides additional protection to vehicles and crews against pressure-activated improvised explosive devices and mines.

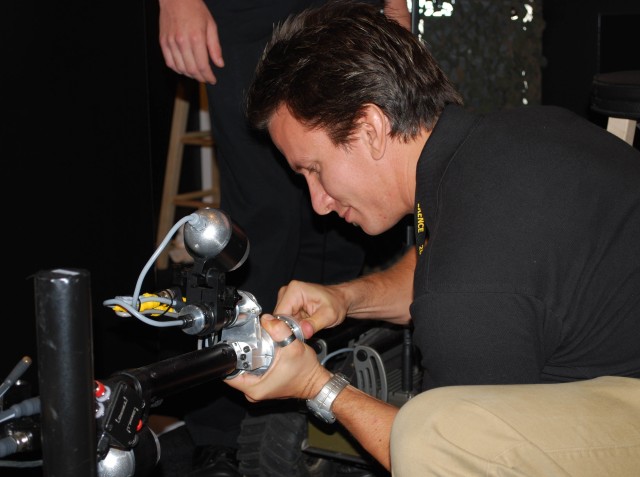

TARDEC showcased the iRobot® Packbot and the Markbot. Specifically, the Packbot-EOD has several missions, including explosive ordnance disposal, route clearance, engineering support, reconnaissance and surveillance. The Markbot IV is a low-cost wheeled reconnaissance robot designed to provide Warfighters with a remote, visual capability. Robots are being increasingly used to extend Warfighter visual capabilities.

"The small robotics market is dramatically growing especially since the onset of the war," said Lonnie Freiburger, TARDEC engineer. He says the Packbot-EOD provides standoff capability to the Soldier which is urgently needed when addressing IED situations on the battlefield.

Social Sharing