The U.S. Army Public Health Command agrees with Ben Franklin that "an ounce of prevention is worth a pound of cure." This is especially true when it comes to preventing disease, injury and disability to active-duty Soldiers.

As budgets shrink, it is more important than ever to demonstrate the health impacts of new military equipment or modifications to current equipment, but this requires objective data to make informed decisions. The USAPHC Health Hazard Assessment Program has developed the Medical Cost-Avoidance Model--a series of tools that can help demonstrate the cost of failing to prevent adverse health consequences.

The HHA Program addresses the potential effects of materiel systems health hazards on the personnel who operate and maintain the systems. As part of the program's assessments, the USAPHC is using this new, data-driven tool.

"The Medical Cost-Avoidance Model can estimate avoidable acquisition life cycle medical costs resulting from the elimination or control of health hazards," explained Cindy Smith, industrial hygienist with the HHA Program. "It relates the medical cost factors that are attributed to health hazards to better justify methods of their elimination or control."

"Mitigating health hazards early in the acquisition process is usually less costly than waiting until later in the process," explained Timothy Kluchinsky Jr., HHA Program manager. "Having a return-on-investment tool available to justify and prioritize mitigation strategies allows materiel developers to make more informed decisions on the materiel being designed."

Health hazards are often inherent in Army materiel and may cause injury or illness at any point in the acquisition life cycle, according to Kluchinsky. If injuries occur, medical treatment costs pose a considerable financial burden to military and veteran healthcare systems, and the resulting lost time degrades productivity and unit readiness.

"Various health hazard types including chemical and biological substances, acoustic and radiation energy, vibration, shock, trauma, and temperature extremes can be evaluated using this model," said Kluchinsky, who holds a doctorate in public health. "The Medical Cost Avoidance Model gives commanders and project management offices a risk-based severity and probability tool designed to estimate the return on investment associated with incorporating mitigation recommendations published in health hazard assessment reports."

"USAPHC health hazard experts assess new or improved materiel by evaluating: types of hazards that exist; injuries or illnesses likely to result from the hazards; level of risk for each hazard; and corrective actions needed to eliminate or control the hazards," explained Smith. "Our health hazard experts report this information to the materiel program management offices responsible for the development and life cycle management of the materiel system."

As part of their assessment, the HHA Program uses the MCAM to predict future health hazard costs based on data from the Military Health System and the Veterans Benefits Administration.

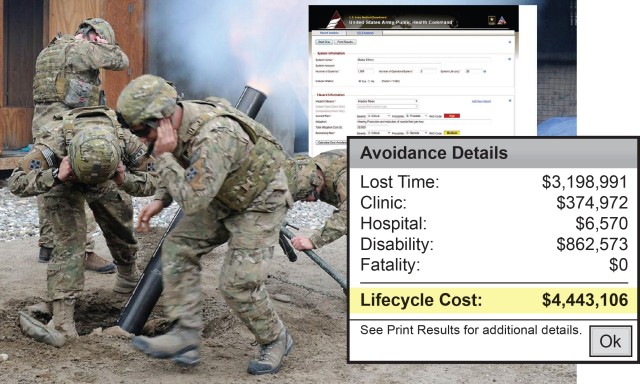

"The primary MCAM function is its ability to estimate total system-related medical and lost-time costs, using the cost factors of lost time, disability and fatality. The MCAM provides a return-on- investment model that is a way of comparing profit or loss to the amount invested," said Smith.

Materiel program management offices can also use the MCAM output to establish health hazard abatement priorities before materiel fielding, and to assess the potential impact on military readiness.

"A single engineering change may eliminate hazard costs across the entire fleet or equipment type. The benefit would be a reduction in lost time and medical-related costs," according to Smith. "Exposure to the causes of injury and disease can trigger a series of possible events: clinic visits, hospitalization, lost time, disability and fatality."

Working with the Army Ergonomics Program on the safe patient-handling initiative Smith used the MCAM and information on the frequency of musculoskeletal disorders suffered by active-duty healthcare providers when manually moving patients to compile the total medical cost of these injuries and compared them to the cost of installing various types of equipment to assist in moving patients.

"The MCAM output demonstrated that there was a significantly lower cost to install safe patient-handling equipment than to pay the medical, disability and lost-time costs associated with not installing the equipment," said Smith. "Using the analysis provided by the MCAM, it was determined that it would be 18 times less expensive to install new equipment than to pay the estimated medical and lost-time costs associated with not installing the equipment."

This ability to project return-on-investment can be a vital tool to acquisition managers according to Kluchinsky.

"The MCAM tool is available on the USAPHC public Web site," said Kluchinsky. "It provides hazard analysis and predicts medical and lost-time costs based on actual Army medical records.

"The MCAM provides the means to optimize and articulate the return on investment (avoidable medical, lost-time, disability, and fatality costs) important to occupational health, preventive medicine, and safety-related investment decision making," he said.

The Medical Cost Avoidance Model is available at: https://usaphcapps.amedd.army.mil/mcam

Social Sharing