A typical day at Logistics Task Force Bagram begins early and ends late but what happens in between changes every day as units turn in equipment to the LTF's Redistribution Property Assistance Team. Equipment is usually turned in because it is excess for the current mission set, or the unit is anticipating the end of their deployment and are following Army standard procedures for managing theater provided equipment.

The Bagram RPAT operation is the primary mission for the LTF and is housed in three warehouses totaling approximately 180,000 square feet. Equipment is also staged in several locations depending on dispositions decisions. RPAT operations are conducted by Soldiers, Department of the Army civilians and contractors and can flex to 24-hour operations to meet mission requirements.

The RPAT accepts rolling and non-rolling stock. Rolling stock usually means vehicles -- ranging in size from small all-terrain utility vehicles, similar to golf carts, to MRAP recovery vehicles with a curb weight of nearly 30 tons. Non-rolling stock can range in size from hand-held devices to shipping containers.

Two of the more unusual items spotted in the Bagram RPAT recently were a USO mobile stage and a dental patient chair with the delivery arm. A shiny brass tuba was spotted on a previous visit -- all in a typical day at LTF Bagram's RPAT.

Some of the equipment turned in will not be retained in the Army inventory. In most cases it will be turned in to Defense Logistics Agency Disposition Services. In order to prepare vehicles for turn in to DLA-DS, LTF personnel conduct through ammo abatement inspections at several points in the process and other personnel remove added-on armor and a laundry list of parts such as seats, insulation and foam pads. Ammo abatement and removal of extraneous materials allow for safe processing of equipment by DLA-DS.

LTF Bagram is headed by Maj. Charles V. Martin who is in his third deployment with the 401st Army Field Support Brigade. Martin, an Army Reserve Soldier is a native of Columbia Mo. and he currently resides in Princeton N.J. His team consists of Soldiers, Department of Army Civilians and contractors. Customer service and getting the units in and out of the RPAT quickly and efficiently are top priorities.

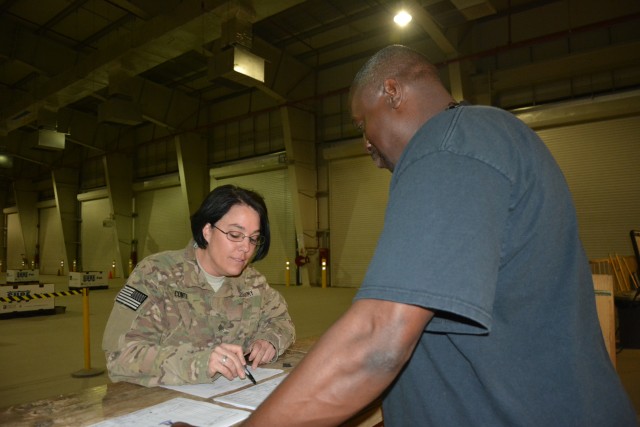

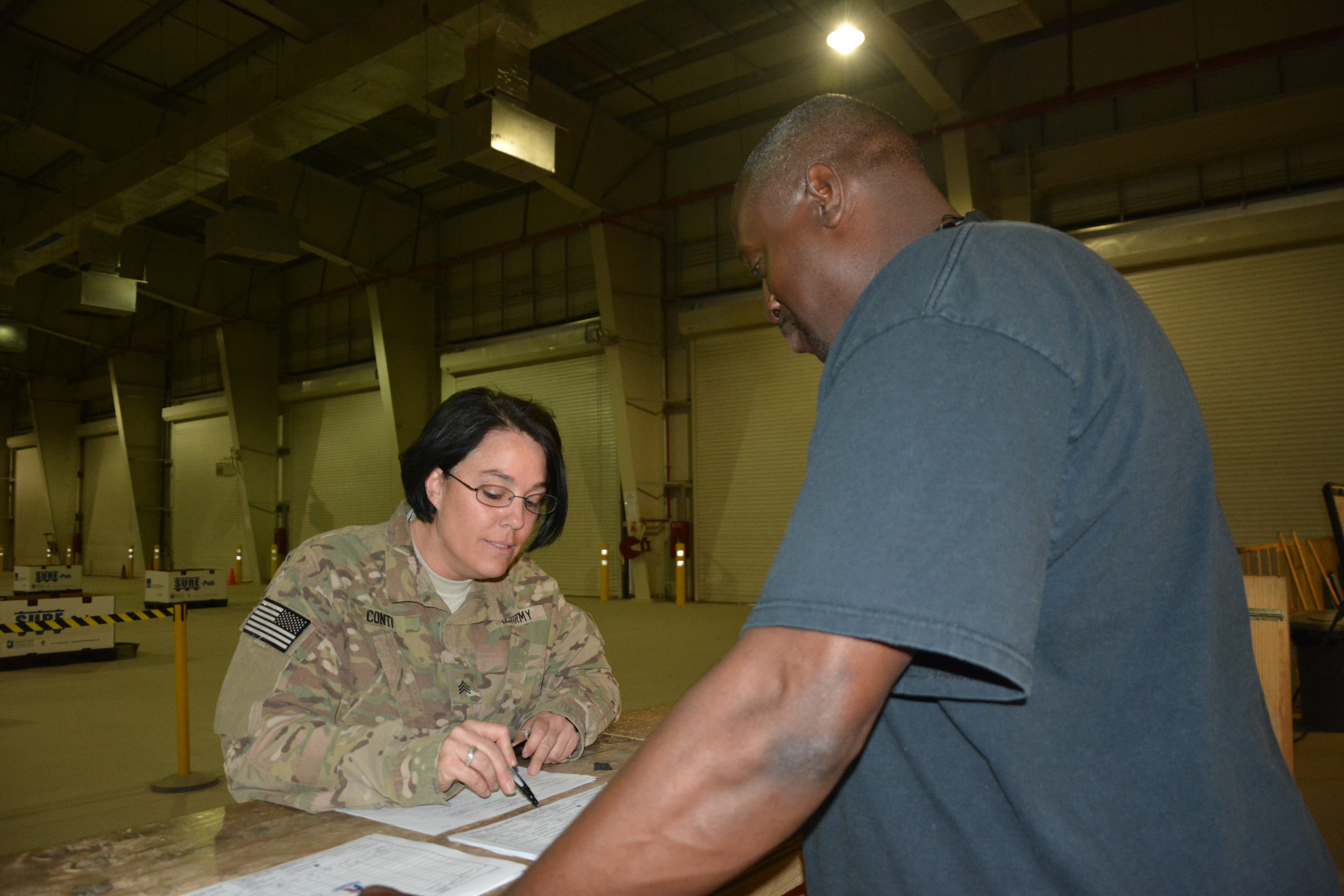

A major step in the RPAT process is relieving the unit of the equipment. This step entails correct paperwork and documentation that allows the RPAT to remove the property from the unit property book and enter it into either the wholesale or retail property books maintained by the RPAT. In either case, the unit is no longer responsible for the equipment and it becomes the responsibility of the LTF to maintain proper accountability throughout the RPAT process.

"Best case is ten to fifteen minutes to get vehicles received and get Soldiers on their way," Martin said.

Once the LTF assumes responsibility for a vehicle, contractors get to work to remove government furnished equipment; remove the overhead gunners protection kit; remove RPG netting and remove antennas. The vehicle is then driven to the weight in motion sensor to be weighed and measured. After WIMS, the vehicle goes to the wash rack for a thorough cleaning and another ammo abatement inspection before being taken to a holding yard.

"Once we sign for it [a vehicle], its receipt to wash rack in 47 minutes," said Martin.

On Apr. 18, a team of AC-First contractors took less than 20 minutes to verify the serial number, move a MRAP All-terrain vehicle, remove RPG netting, remove the overhead gunner's protection kit, reposition the spare tire and sweep up the nuts and bolts that held the netting on the MATV. The MATV was then ready for another ammo abatement inspection.

Frederick 'Freddie' Reynolds, an AC-First supervisor in the rolling stock area, said his team comes from many nations and speaks at least five different languages but they work together quickly and safely to remove equipment from the vehicle so it could be prepared for a future mission.

Non-rolling stock, which includes items removed from vehicles, is sorted and put into kicker boxes. Due to the numbers of NRS pieces, the wide range of sizes and the fact that there are sometimes only one or two unusual items, processing these NRS takes considerable longer than it takes to process a vehicle such as an MRAP.

Equipment that is being retained by the Army will be staged and await transport. Captain David E. McCormick and Sgt. 1st Class Ivan K. Line, LTF-BAF flight line liaison officers are the link from the LTF to the U.S. Air Force operations that move equipment to support Army missions.

Martin proudly added that there have been 'zero injuries' while he has been the officer in charge.

Social Sharing