ABERDEEN PROVING GROUND, Md. -- Fuel is the second largest transported item in the field next to water. As a result, fuel truck convoys that deliver fuel are vulnerable to enemy attacks, which have resulted in loss of money, time and lives.

To combat this problem, scientists and engineers from the U.S. Army Research, Development and Engineering Command are working to lessen the reliance on fuel truck convoys by reducing the amount of military fuel, called Jet Propellant 8, or JP-8, the Army needs in theater and improving the efficiency of its use.

One way they are doing this is through reforming JP-8 so that it can be used in efficient portable energy systems, like fuel cells and other novel power sources, which primarily operate on hydrogen or other cleaner fuels.

"The goal is to take the logistic fuel that's already all over the battlefield, that's there and available to the Soldiers, and convert it to something that can be used in smaller and renewable systems," said Steve Slane, RDECOM's communications-electronics center, or CERDEC, Command, Power and Integration Directorate, Power Generation and Alternative Energy Branch chief.

Engineers and scientists from CERDEC, along with RDECOM's Army Research Laboratory and Tank Automotive Research, Development and Engineering Center are working to reform JP-8 and integrate it into systems so it can be converted seamlessly and locally.

"Fuel reforming is one of those leap-ahead technologies that could allow JP-8 to be transformed into valuable fuels that can be used and generated on the battlefield forward. So instead of shipping propane and methanol and kerosene and gasoline, why not reform JP-8 locally to power those systems?" said Slane.

The process of reforming fuel entails high-temperature catalytic reactions that covert a liquid fuel, in this case JP-8, into a lighter, gaseous fuel.

This comes with two main challenges due to the sulfur contained within JP-8 and its complex composition, said Dr. Terry DuBois, subject matter expert in fuel reforming and combustion in CERDEC CP&I's Power Division.

First, sulfur can deactivate catalysts, which means it can limit the life or poison catalysts during the reforming process and make it inoperable. Second, sulfur can accelerate carbon formation, where solid carbon particles form in the reactor, clog the flow of the reactor or deactivate catalysts and cause it to fail, said DuBois.

"Those are two big challenges for us in reforming; how do we transform JP-8 to a hydrogen rich stream and deal with the two mechanisms for killing the reactor?" said DuBois.

This fuel transformation effort is a main focus for CERDEC, TARDEC and ARL.

The challenge is developing a practical fuel reformation process for better energy conversion that would have to be portable, quick and easy to use, said Dr. Zachary Dunbar, an ARL fuel cell team member.

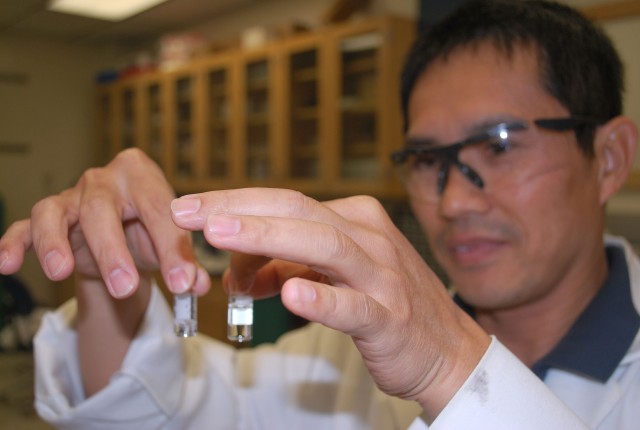

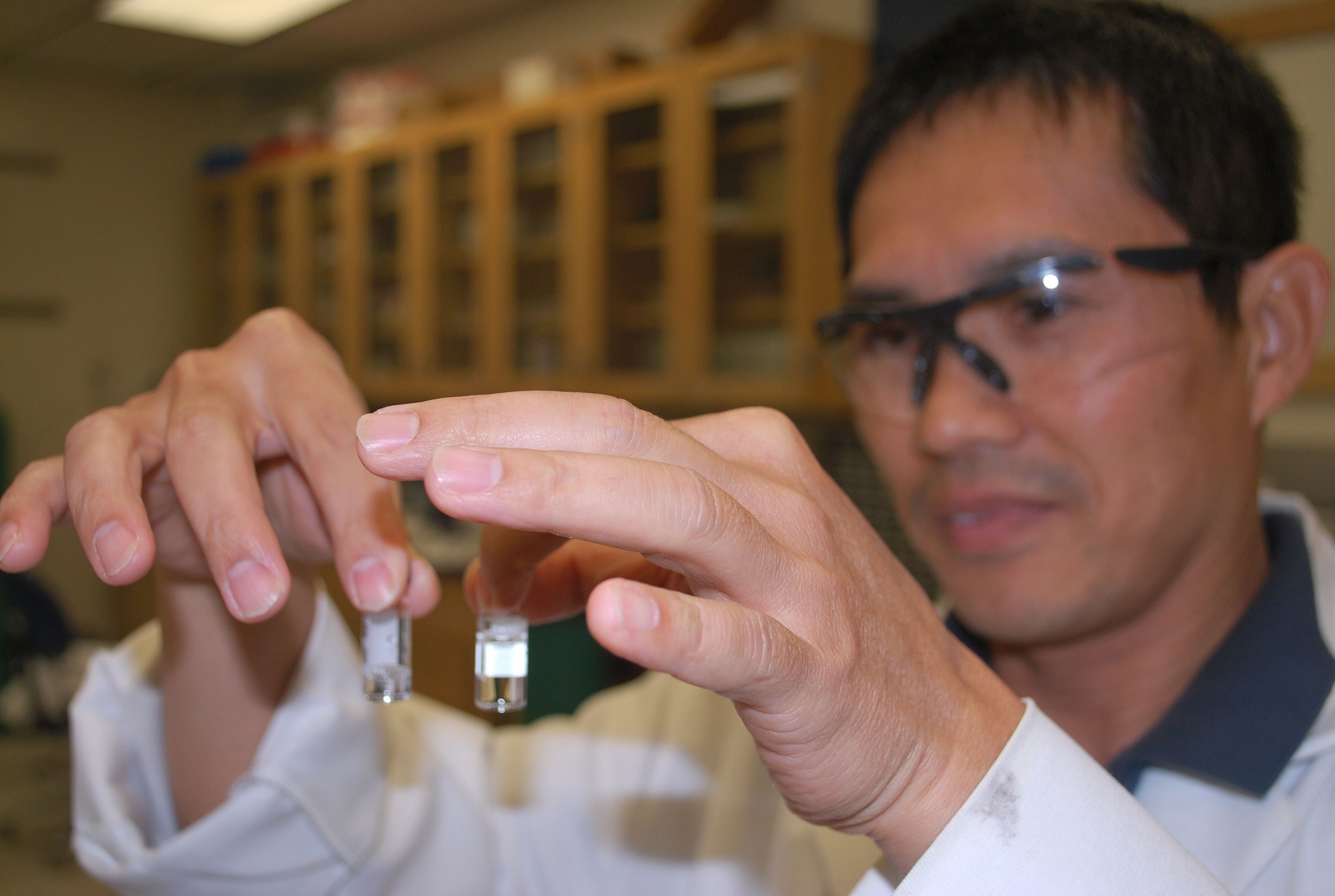

Dr. Dat Tran, ARL fuel cell team lead, has tested at least 300 different combinations of materials during the last four years while he has been investigating fuel reforming with the team, he said.

"JP-8 is a complicated and dirty fuel. The sulfur is a huge problem because it can hurt the fuel cells," Tran said. "Sulfur has many different compounds that behave differently. The compounds in sulfur make it hard to find an agreeable material."

While ARL conducts the basic research of fuel reforming, CERDEC integrates the basic research into a system and evaluates it, while also performing further research and development of fuel reforming materials.

"Both of the efforts that we have ongoing are focused on addressing desulfurization of JP-8, and ARL is pursuing complimentary R&D on unique materials for sulfur absorption. In addition, ARL is looking at membranes that can selectively separate hydrogen from the gaseous reformed fuel stream so that you have a pure hydrogen stream," said DuBois.

"CERDEC's in-house program is looking at catalytic materials. So we have ongoing research work evaluating different catalytic materials and how well they stand up to chemical compounds found in JP-8. We are also evaluating sulfur absorbent materials and processes on a long-term basis," said DuBois.

TARDEC also works in fuel reforming by integrating it into fuel cell power systems.

"The main applications are combat and tactical vehicle Auxiliary Power Units, silent propulsion for Unmanned Ground Systems and extending the silent range of electric vehicles for scout or reconnaissance missions," said Kevin Centeck, TARDEC Non-primary Power Systems team lead.

"TARDEC is also investigating the requirements for a fuel reformation system to be integrated with a commercial automotive fuel cell stack, which could help reduce cost and increase reliability of fuel cell power systems," said Centeck.

CERDEC, ARL and TARDEC collaborate on their fuel reforming efforts for the Army through Fuel Cell Test and Integration Working Groups with other Defense Department partners through quarterly program and design reviews.

CERDEC is taking fuel reforming one step further by working to integrate its efforts into its Energy Informed Operations, or EIO, initiative, which aims to make power systems "smart" by enabling "smarter" monitoring on the systems as well as integrating them into a smart tactical micro grid.

This smart technology will enable and inform Soldiers with data such as, "How much fuel do I have left? When are the fuel trucks coming next? What's my energy status?" said Slane.

"The efficiencies gained by using grid data to control power and inform operations will increase availability and reliability of power while reducing the burden of fuel logistics, storage and cost," said Slane. "CERDEC CP&I is uniquely qualified to cover all this because we have our mechanical engineers who are working fuel reformation and combustion but we also have engineers within the mission command community here working on intelligent micro-grids through EIO."

RDECOM will continue to work to address the challenges with fuel reforming and integrating it into a full power system that can then be transitioned to the field.

"Reducing the amount of fuel is really a goal of what this organization is about," said Slane. "Fuel reforming is one of the key technology areas that will enable us to reduce fuel on the battlefield, reduce the amount of truck convoys, the amount of storage needed and the cost of operating in austere environments."

---------------

CERDEC, ARL and TARDEC are part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

*This article originally appeared in RDECOM's Army Technology Magazine March 2014 issue.

Related Links:

Army Technology Magazine: March 2014

U.S. Army Research, Development and Engineering Command

Army.mil: Science and Technology News

Communications-Electronics Research, Development and Engineering Center

Social Sharing