Professional logisticians working in the field understand that providing the best possible logistics support for the warfighter in an ever changing environment is a complicated and continuous effort. But planning logistics can be even more complicated.

Usability is the governing factor for successfully implementing a logistics support framework. The concept needs to be simple to understand, sound in construct, and scalable to a multitude of situations.

Complex framework concepts have their place in the science of critical logistics information, but if they are too complicated and rigid in execution, then their applications are limited to a small subset of circumstances. Too many hard-and-fast rules and requirements restrain a planner's ability to tailor data and information. As a result, vital information might be tossed aside if it does not fit neatly into the complex framework.

Conversely, a system with too vague of a structure is just as difficult to use. A method with no rules or constraints provides a veritable tsunami of information and circumstances that clogs thinking and clouds perception. Logisticians are forced to wade through information, both pertinent and not, to determine what is applicable to their situations.

Even though no framework is completely right or wrong , the most useful example is one that provides a basic construct with a core, overarching rule set that ensures maximum effort and focus is provided to the task at hand. The basic rules provide the metaphorical right and left limits, and the framework is flexible enough to adapt to the current situation.

THE GAP REDUCTION MODEL

The Gap Reduction Model provides a framework for logisticians to analyze challenges and situations. It is not a replacement for other proven frameworks. It is simply another means of creating situational awareness for the logistician. In its most basic structure, the model provides a logistics perspective of the support required by operating forces.

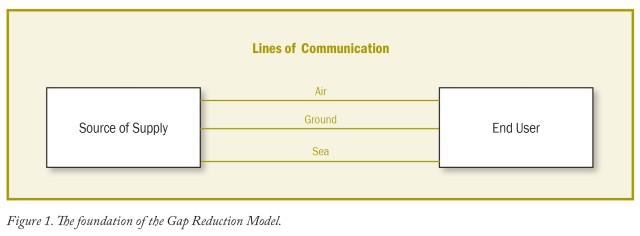

The model uses a foundation that is almost deceptively simple and consists of a source of supply, the end user, and the gap between, which the logistician must bridge with the lines of communication. (See figure 1.)

At first glance it may seem that the model has too little structure. However, the value of the model comes from the ability to build on this foundation to match any situation. Logisticians often want to see an entire network of gaps across their area of responsibility. While this broad view can be helpful, the Gap Reduction Model was designed to force logisticians to break larger networks into workable segments that can be analyzed and adjusted appropriately. Keeping this in mind, we will focus on a single gap for this article.

DEFINITIONS

Before we add onto the basic framework, the terminology of the model needs defining.

END USER. This is any function, unit, or person that requires logistics support from the source of supply. The end user is typically called the war fighter. Companies, battalions, squadrons, and even brigades or wings all require support from the source of supply and fit the basic description of a war fighter. The end user is not limited to military fighting formations. Humanitarian relief forces, nongovernmental organizations, civil-response organizations, and others can be classified as end users. The need for support is the only requirement to be an end user.

SOURCE OF SUPPLY. This term references any organization or entity that supports the end user. Sources of supply can include warehouses, forward operating bases, aerial ports, sea ports, repair depots, host nation sources, or even industrial production sites. Logisticians at these sources of supply will typically have to provide support to many end users concurrently, requiring the management of multiple gap models.

LINE OF COMMUNICATION. The conduit that carries the logistics support between the source of supply and the end user is called a line of communication. There are three primary types, or modes, of lines of communication--air, sea, and ground movement. Each mode can be comparatively measured in terms of time, cost, and capacity.

Air movement, which includes both fixed- and rotary-wing assets, delivers the ability to rapidly move materiel and logistics support to nearly any point on the globe unimpeded by most geographical restrictions. However, air movement is expensive and limited in volume when compared to the other modes of transportation.

Fixed-wing air movement requires airfields capable of handling tasked airframes. Rotary-wing air movement has far fewer physical requirements for operating locations, but it also has a more limited capacity. Finally, air movement has the advantage of bypassing most enemy activities and reduces the need for route clearance of ground lines of communication.1

Logisticians provide a mind boggling amount of support through sea movement. Transiting the oceans and interior waterways, sea movement has the capacity to move large volumes of equipment and supplies in comparison to the other modes.

The trade-offs for such massive capacity are slower speed and the fact that movement can only take place between sea ports capable of loading and offloading the requisite vessel.2 If the end user is located away from the port facilities, then the logistician is required to either completely rely on another mode or use multiple modes to deliver the required support.

Ground movement includes both vehicle and rail movement and is often the final link in moving support to the end user. Although ground transportation pales in comparison to air in terms of speed and sea in terms of capacity, it provides greater flexibility for the logistician when paired with one of the other modes.3

When representing the different lines of communication on the gap model, each mode is shown with its own line. This allows logisticians to visualize all options. This view ensures they are prepared to provide alternate means if access is lost to any line of communication. Depending on the situation, one, two, or all three lines can be represented on the model.

ACCESS AND SECURITY

Logisticians must ensure they have access and security for the lines of communication they want to use to provide support. In the Gap Reduction Model, access includes both political and physical considerations. Political access means that the relevant political entities have granted approval for transit through the lines of communication. For example, political access must be granted before a U.S. aircraft travels an air line of communication that transits another country's air space.

Physical access is the capability of the line of communication to handle the required transport vehicle. The infrastructure determines physical access for the specified line of communication.4 Physical access is not attained if a ship cannot dock at the port or a truck cannot transit the road network because of damage or poor infrastructure. If either political or physical access is not achievable, then the line of communication is not viable.

No matter the location or situation, no line of communication is ever 100-percent secure. In an active conflict zone, enemy action can restrict or disable lines of communication that are vital to supporting the end user.5 Likewise, in humanitarian relief situations, inclement weather or the destruction of infrastructure can compromise the security of a line of communication.

Understanding the security threat is the responsibility of logisticians because they will need to make recommendations based on the ability to mitigate risk and the level of acceptable risk determined by the value of the support the line of communication provides.

GAP REDUCTION

The logistician's primary mission is to provide the best possible support to the end user; the Gap Reduction Model seeks to further refine that responsibility. The logistician needs to shorten the gap between the source of supply and the end user to provide better support. There are two ways to accomplish this task--either shorten the physical distance between the two or shorten the time it takes to travel the line of communication.

To shorten the distance between the end user and the source of supply, an intuitive method is to move closer to the end user. Although relocating is a potential solution, generally it is not an easy proposition. Sources of supply are typically well established locations that occupy strategic locations in conjunction with major sea or aerial ports and service multiple end users.

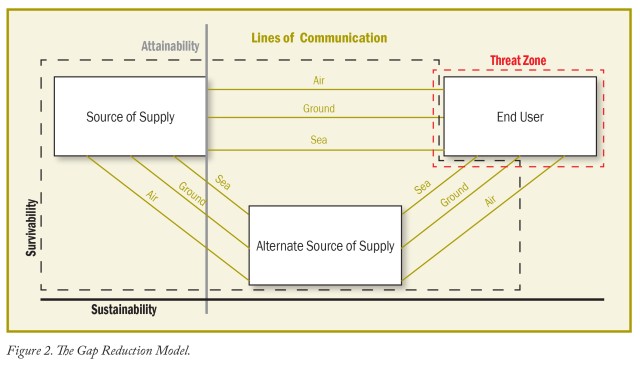

Instead of shifting the entire source of supply, logisticians have other tools at their disposal to significantly shorten the distance to the end user: using another pre-existing source of supply or pre-positioning materiel closer to the end user's operating location. Keep in mind that, even if an alternative source of supply is used, the original source is still available for additional support or for classes of supply that are not available through the alternate source. (See figure 2.)

When using an alternate source of supply, the requirements are increased and the system becomes more complicated. Logisticians must maintain the lines of communication for the alternate source in addition to the original lines of communication. Although complexity is typically considered the bane of operations, adding complexity is acceptable if it enables the logistician to provide better support to the end user.

The other method to shorten the gap between the source of supply and the end user is to reduce the time it takes for the support to travel the line of communication. Reducing transit time is typically accomplished by using different lines of communication. The Gap Reduction Model forces the logistician to review each option individually and as a multimodal system option. The key is to balance the use of the different modes.

THREAT

When working to close a gap, many factors must be taken into account, including cost, manpower, facilities, transportation, and, most importantly, the threat. Operations, regardless of the scale or location, must take into account threats, from both enemy forces and environmental impacts, which have the potential to interrupt support. It is important that logisticians recognize these potential threats and maintain the bulk of their logistics support outside of the threat zone.

In a high-threat insurgency environment, the threat has the potential to encompass the end user and the entire line of communication. In a conventional force-on-force conflict, the threat may be much more restricted to a specific battlespace. A red dashed line surrounding the end user represents a threat zone that varies with each operational environment. (See figure 2.)

This addition to the model enables logisticians to evaluate where the threats lie in order to plan potential sources of supply and lines of communication. The impetus to keep logisticians and the logistics system outside of the threat zone is not that logisticians themselves cannot or will not fight. Logisticians have to balance responsiveness and the protection of their sources of supply and lines of communication.

PRINCIPLES OF LOGISTICS

The final level of the Gap Reduction Model encompasses the three key principles of logistics--attainability, survivability, and sustainability. Although all of the principles of logistics can be applied to the gap model, to maintain the focus on usability, I have decided to focus on just these three.

ATTAINABILITY. To achieve attainability, the logistician needs to make sure that the end user has all the required support for the operation as planned.6 This means that the mission planned by the end user will not include every potential set of circumstances that may affect execution.

Logisticians must follow the same mentality, wherein they provide the end user with the support required for the mission as it is conceived and executed. Logisticians must ask themselves if they have provided everything the war fighter has identified as being required for attainability before the mission starts and if any shortfalls have been identified that need to be accounted for by the operational commander.

It is vital that logisticians peer into the fog of war and prepare to respond to additional requirements that evolve after mission execution. Pre-positioning, readying, packaging, and moving forward to alternate sources of supply are all actions logisticians can take to provide additional support to the end user.

It is sometimes labor intensive and frustrating to prepare additional support that is not used, but if the support is required and it means the difference between life and death to the end user, then ultimately it is worthwhile. Attainability is depicted as a vertical line between the initial source of supply and the lines of communication. (See figure 2.)

SURVIVABILITY. Defined as the "capacity of an organization to prevail in the face of potential threats," survivability correlates with the imperative that the logistics system stays removed from the threat zone to the maximum extent possible.7 Logisticians have to balance keeping the support close enough to the end user to provide the best possible support while at the same time ensuring the survival of the system. It is important to note that survivability is not geared to the survival of personnel or assets. Instead, it is focused on ensuring that the entire logistics system survives.

One of the primary ways logisticians provide survivability is to use multiple lines of communication. For example, ground lines of communication can move a large amount of support fairly rapidly, but they have greater potential to be disrupted by enemy action, natural disasters, or inclement weather.

To ensure that the end user receives the support required, logisticians will often add an air line of communication to shift the burden if the ground mode is disrupted. Another way of providing survivability is to use alternate sources of supply to augment or replace the primary.

The area of survivability ties directly to the threat zone. As one line shifts, the other also must shift. Afghanistan is an example of a high-threat insurgency environment, and the threat is all around. As soon as logistics support leaves the confines of the source of supply, it enters the active threat zone. The only areas where the logisticians can affect survivability are at the locations that house the sources of supply. In this type of environment, mitigating risk to the system consists primarily of using the mode that offers the least risk, typically air movement, and relying on alternate sources of supply that may be less threatened.

The model only identifies the logistics capabilities that must be survivable or redundant; it does not provide threat mitigation options or threat assessments. It is an awareness tool to ensure logisticians understand the threats and their responsibilities. In figure 2, survivability is depicted as the dashed line surrounding the different sources of supply and the lines of communication all the way up to the end user. Note that the line of survivability extends into the threat zone.

SUSTAINABILITY. This final and most important logistics principle of the Gap Reduction Model is the concept of "a function of providing for and maintaining those levels of ready forces, materiel, and consumables necessary to support military effort."8 Providing overwhelming logistics support to end users for extended periods of time is the hallmark of U.S. military logistics.

Sustainability must always be incorporated into the logistics system since no plan ever proceeds exactly as planned. Even if an operation is projected to take only a couple of hours, logisticians must have a plan for the sustainment of the end user when--not if--circumstances change. If the situation changes and the duration and scale of the operation expand, then the plan for sustainability developed by the logisticians in the initial stages needs to be put in motion.

Sustainability must be tailored to the size of the end users and based on their priorities. It is imperative that the requirements come directly from the end users so superfluous materiel and support do not occupy limited space in the lines of communication.

The model is designed to demonstrate the need and fluctuation of sustainability. The model forces the planner to work out the potential logistics needs in the event of an escalation of the operation. This ensures the logistician is prepared to respond.

Sustainability in the model in figure 2 is a horizontal line that spans the breadth of the logistics system. It crosses both the survivability and threat lines to encompass both the end user and the different sources of supply. This line showcases that logisticians can provide the identified and required support to the end user across the spectrum of mission execution.

The strength of the Gap Reduction Model lies in its ability to break out the different end users and illustrate how the support flows to their operating locations in a simple and understandable framework. Logisticians can balance the information flowing in with the different lines of communications available and the requirements levied by the end user. This ability takes a fair amount of time and experience to develop.

The model is not necessarily the only way to analyze situations; it is just a different way. It is intended not to replace current methods that are used but to provide another tool for logisticians. Ultimately, all of these methods are just that--tools. The knowledge, skill, and experience of the individual logistician will determine the success in providing support.

________________________________________________________________________________________________

Capt. Michael Carter, USAF, is the operations officer for the 75th Logistics Readiness Squadron, Hill Air Force Base, Utah. He wrote this article while serving as faculty at the Air Force Institute of Technology's School of Systems and Logistics, Wright Patterson Air Force Base, Ohio. He holds a bachelor's degree from Wright State University and an MBA from Touro University International.

________________________________________________________________________________________________

ENDNOTES:

1 Army Tactics, Techniques, and Procedures 4-0.1, Army Theater Distribution, Department of the Army, Washington, D.C., May 20, 2011, p. 3--15.

2 Joint Publication 4-01.2, Sealift Support to Joint Operations, Office of the Joint Staff, Washington D.C., June 22, 2012, p. I-2.

3 Army Tactics, Techniques, and Procedures 4-0.1, p. 3-8.

4 Joint Publication 3-35, Deployment and Redeployment Operations, Office of the Joint Staff, Washington D.C., May 7, 2007, p. III-7.

5 Ibid., p. III-5.

6 Joint Publication 4-0, Joint Logistics, Office of the Joint Staff, Washington, D.C., July 18, 2008, p. xvi.

7 Ibid., p. xvii.

8 Ibid., p. xvi.

________________________________________________________________________________________________

Editor's Note: Jerry Stonecipher, Air Force Institute of Technology, School of Systems and Logistics, created the Gap Reduction Model to teach at the school.

This article was published in the January-February 2014 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing