ABERDEEN PROVING GROUND, Md. -- The U.S. Army Edgewood Chemical Biological Center (ECBC) has long supported the non-proliferation of chemical weapons and the demilitarization of their stockpiles and destruction facilities. These two areas reflect the mission of the Organisation for the Prohibition of Chemical Weapons (OPCW), which will be awarded the 2013 Nobel Peace Prize Dec. 10 "for its extensive efforts to eliminate chemical weapons."

Sixteen years after the independent, autonomous international organization based in The Hague, The Netherlands, administered the Chemical Weapons Convention (CWC) in 1997, 190 member states have ratified the treaty, including the newly joined Syrian Arab Republic on Oct. 14, 2013. The CWC is an arms control agreement that outlaws the production, stockpiling and use of chemical weapons. The OPCW also has a working relationship with the United Nations to promote peace, disarmament and international cooperation; and ECBC has supported these efforts in significant ways.

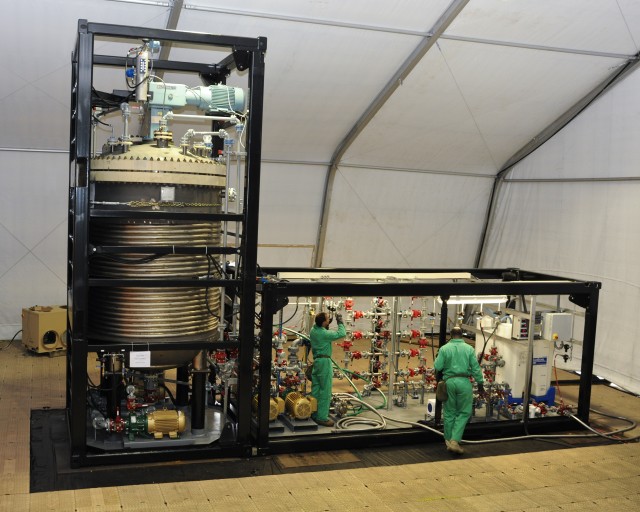

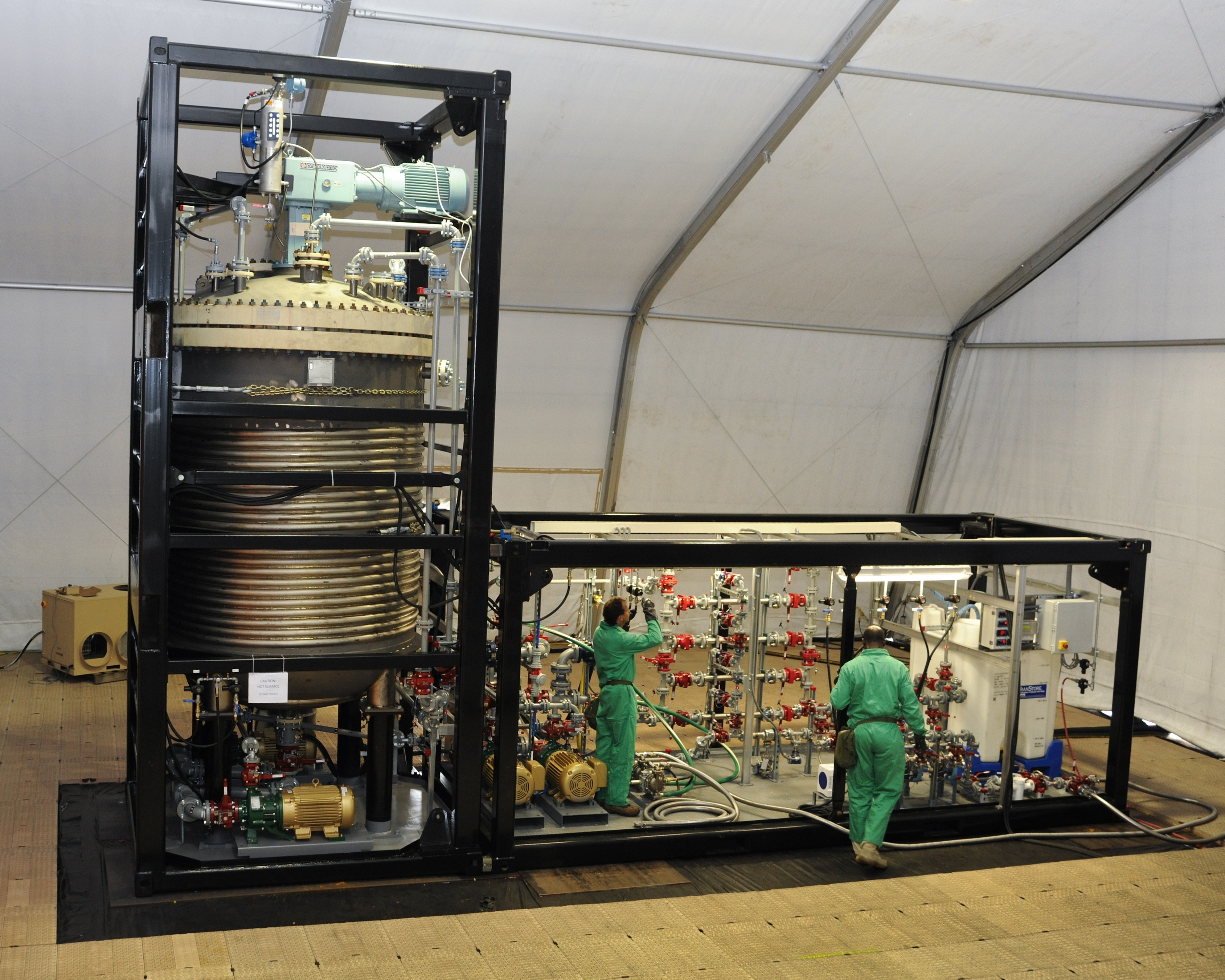

One of ECBC's core competencies is chemical demilitarization field operations. Nearly a year ago, the U.S. Department of Defense (DoD) identified a capability gap in chemical agent disposal operations and sought a solution that would meet mission critical needs by the following summer. ECBC had only six months to produce an operational model of a new transportable elimination technology that could neutralize chemical warfare materiel: the Field Deployable Hydrolysis System (FDHS). Through unprecedented collaborative efforts across multiple government organizations, ECBC led the FDHS effort through full lifecycle development, from design and fabrication to engineering and test evaluation of the system. As a result, the FDHS can neutralize bulk amounts of known chemical warfare agents and their precursors at a 99.9 percent destruction efficiency rate, converting chemical warfare materiel into compounds not usable as weapons.

"The most difficult aspect of designing a system in such a short time period was the need to concurrently perform tasks that would normally be performed sequentially," said Adam Baker, CBARR chemical engineer. "Equipment was already being procured while reaction chemistry and skid design were still being finalized. To overcome this challenge, ECBC and the Joint Program Executive Office for Chemical and Biological Defense's Joint Project Manager for Elimination (JPM-E) incorporated proven technology to the greatest extent possible, which helped keep late design changes to a minimum."

According to Baker, the design team included personnel from ECBC and the JPM-E, formerly known as the Chemical Materials Activity (CMA), which greatly enhanced the in-house capabilities required to complete such a difficult task. In February 2013, the Defense Threat Reduction Agency (DTRA) provided initial funding that enabled the integrated design team to capitalize on the interagency partnership's shared personnel, resources and expertise. ECBC had two primary roles throughout the design process: manage project execution with DTRA and implement the design from the standpoint of the system's operator.

The CBARR unit, comprised of operators, maintenance and safety experts, were utilized from the start of the project to ensure the FDHS product could be safely transported and functionally perform in the expected operational environments. As a result of the 20-week collaborative design phase, the FDHS is a self-sufficient system that includes power generators and a laboratory that is fully capable onsite, needing only consumable materials such as water, reagents and fuel to operate. The system can be set up within 10 days and is equipped with redundant and critical systems that ensure maximum system availability. Should the FDHS be deployed, a crew of 15 trained personnel, including SME support from CBARR, would be needed each shift for 24/7 operational capability.

"The process was a rare opportunity for CBARR to work collaboratively with a large number of organizations within and outside of ECBC. One lesson learned from this project is that ECBC can greatly enhance its capabilities by working collaboratively with other organizations that have complementary skill sets," said Baker.

On June 27, 2013, ECBC and DTRA signed a technology transfer agreement with the Joint Program Executive Office for Chemical and Biological Defense (JPEO-CBD). The transition signified advanced development and future integration into the Chemical Biological Defense Program Portfolio.

In 1997, the OPCW began conducting international chemical weapons inspections as part of CWC compliance and verification. The Organisation has a "verification regime" designed to collect relevant facts and discover any violations among State Parties, requiring declaration of chemical weapons or related facilities acquired since 1946. According to ECBC's Treaty Compliance Officer, the CWC specifies threshold amounts that are required for particular types of chemicals and verifies these declarations through routine inspections of designated facilities.

ECBC's Chemical Transfer Facility (CTF) is one such facility, and serves as the single repository for the Army's research and development stock of toxic chemical agents. The CTF was designated as the only U.S. declared Single Small Scale Facility (SSSF) under the CWC, and is the only U.S. declared Chemical Weapons Storage Facility and Chemical Weapons Destruction Facility. Chemical agents stored at the CTF are used to conduct defensive research and development for the DOD, whose research is imperative to maintaining an effective defense posture against the new world chemical threat. In support of this mission, CBARR personnel are responsible for the receipt, triage and screening of "unknowns." Agent preparation occurs through synthesis or purification, as well as the packaging and shipment of neat and dilute agent throughout the DoD.

In addition to the FDHS elimination technology, the CTF also supports the U.S. chemical agent disposal program, including "drill and drain" operations completed downrange at the Munitions Assessment and Processing System (MAPS) facility. All chemical agents used in studies are prepared and shipped from the CTF, where bench scale and large volume neutralization experiments can be conducted by CBARR personnel. The CTF team is extensively trained in areas such as safety and health, proper use and application of PPE, hazardous materials packaging and transportation, storage and handling.

The ECBC Treaty Compliance Officer said the most important regulation under the CWC is remaining under the designated agent quantities for permitted purposes. ECBC also adheres to Army regulations and inventory is monitored through rigorously data management processes and best practices. According to the OPCW website, results from routine inspections are reported to the Director-General. If the report contains any uncertainties, a challenge inspection may occur. ECBC has remained CWC-compliant since 1997.

ECBC continues to be a pioneer in the area of forensic analysis for monitoring the proliferation of weapons of mass destruction (WMD), as well as sample analysis associated with possible terrorist attacks or breaches of security. Located at Aberdeen Proving Ground, Md., ECBC's Forensic Analytical Laboratory received an "A" grade in the latest international proficiency test (33rd OPCW IPT) administered by the OPCW in 2013.

"Conducting tests like these are critical for ECBC and for the nation," said Stan Ostazeski, Ph.D., Forensic Analytical Center Chief. "It brings sponsors with analytical needs to ECBC, and our "A"-grade offers confidence that we can successfully perform. Information like this is essential to our nation's security."

ECBC is one of two OPCW-designated laboratories in the United States; the other is at Lawrence Livermore National Laboratory in California. Of the 12 labs worldwide that participated in the proficiency test, only two received an "A," and two laboratories received a "B," the minimum grade required for a laboratory to maintain its status as an OPCW-designated laboratory. There are currently 21 OPCW-designated laboratories worldwide that specialize in the analysis of samples for chemical warfare agents, byproducts, precursors and other compounds of interest. These laboratories must adhere to strict administrative guidelines, maintain accreditation by an internationally recognized organization and successfully complete an annual international proficiency test in order to maintain their status as an OPCW-designated lab.

The participating laboratories have 15 calendar days from the time they receive the samples to complete the analysis and reporting required by the proficiency test. During the 33rd OPCW IPT, a designated lab from China prepared some extremely challenging samples for the candidate labs to analyze, including a scheduled compound that did not exist in any databases. A designated lab from Singapore was the evaluation laboratory that checked the reports of the participating labs to validate their conclusions and recommend scoring to the Director General who issued the official scores.

"The goal of preparing the test is to replicate real world samples. However, the labs preparing the samples know what compounds might hide or mimic reportable compounds, so the test samples are likely more difficult than real world samples. They want to make these tests as difficult as they can to ensure that we really can handle threats," said Ostazeski.

A couple of weeks before the official samples are released, the OPCW publishes a scenario with a couple of clues as to what the real test will be. Within the scenario, teams are informed on whether to expect soil, water, organic solvent, or surface material samples, and other minor clues that could be helpful with preparation. With that information, the team is able to get their processes in place and set up a "toolbox" that may best help them with the actual sample. Then, the real sample is released and the hard work really begins.

Ostazeski explained that the team receives six samples in vials with two different matrices. "For example, a team can receive three vials of soil and three of water. You analyze all six knowing that one of the three of each matrix will not contain any reportable compounds," Ostazeski said. Two of the other samples are considered to be the actual unknown samples so they may or may not contain reportable compounds.

When the testing begins, one of the most important aspects is ensuring that scientists are reporting only information relevant to the OPCW and the scenario for the test. Reporting a compound that is not present in the sample or that is not relevant is considered a false positive and results in an automatic failure. Unlike some analyses, the scientists are locating and identifying unknown compounds as opposed to attempting to confirm the presence or absence of a known substance.

Sorting through the relevant and irrelevant materials requires teamwork. About 16 people are involved in the proficiency test. "When we come together for this testing, it is all hands on deck," Dr. Ostazeski said. "It's rare to find a team pulling together like this team does during the OPCW process."

ECBC's Forensic Analytical Center was the first U.S. laboratory to become a designated OPCW laboratory. They were given that status by the Director General of the OPCW in 1996. Although testing takes place on an annual basis, the total process takes place in a three-year timeframe. In order to maintain OPCW accreditation, laboratories must maintain a three-year rolling average of at least two "As" and one "B."

================================

ECBC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Related Links:

Army.mil: Science and Technology News

Social Sharing