ABERDEEN PROVING GROUND, Md. -- The U.S. Army Edgewood Chemical Biological Center is known for providing onsite field support at locations across the country. Now, its Chemical Biological Application and Risk Reduction Business Unit is using this capability back home at the Edgewood Area of Aberdeen Proving Ground. Since May 20, a team of CBARR personnel have provided air monitoring and sample analysis support for the E3200 block building characterization effort.

The project is led by the U.S. Army Engineering and Support Center, Huntsville, Ala., and operated by prime contractor Parsons.

"Because of the history of the buildings, there is the potential that chemical warfare materials were used and there may be some building contamination as a result," said Bill Bruchey, CBARR project manager. "It's the reason why we are supporting the effort to characterize the area in question."

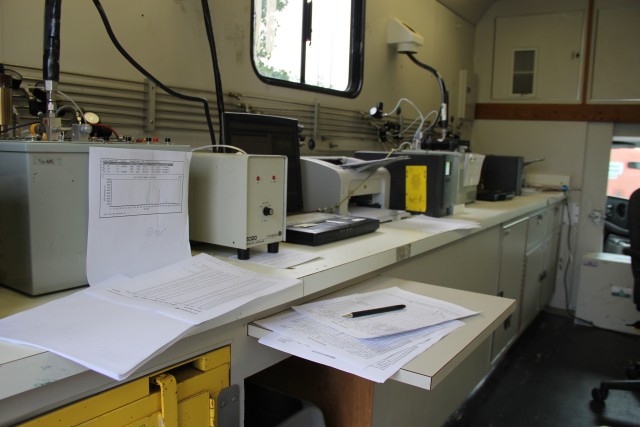

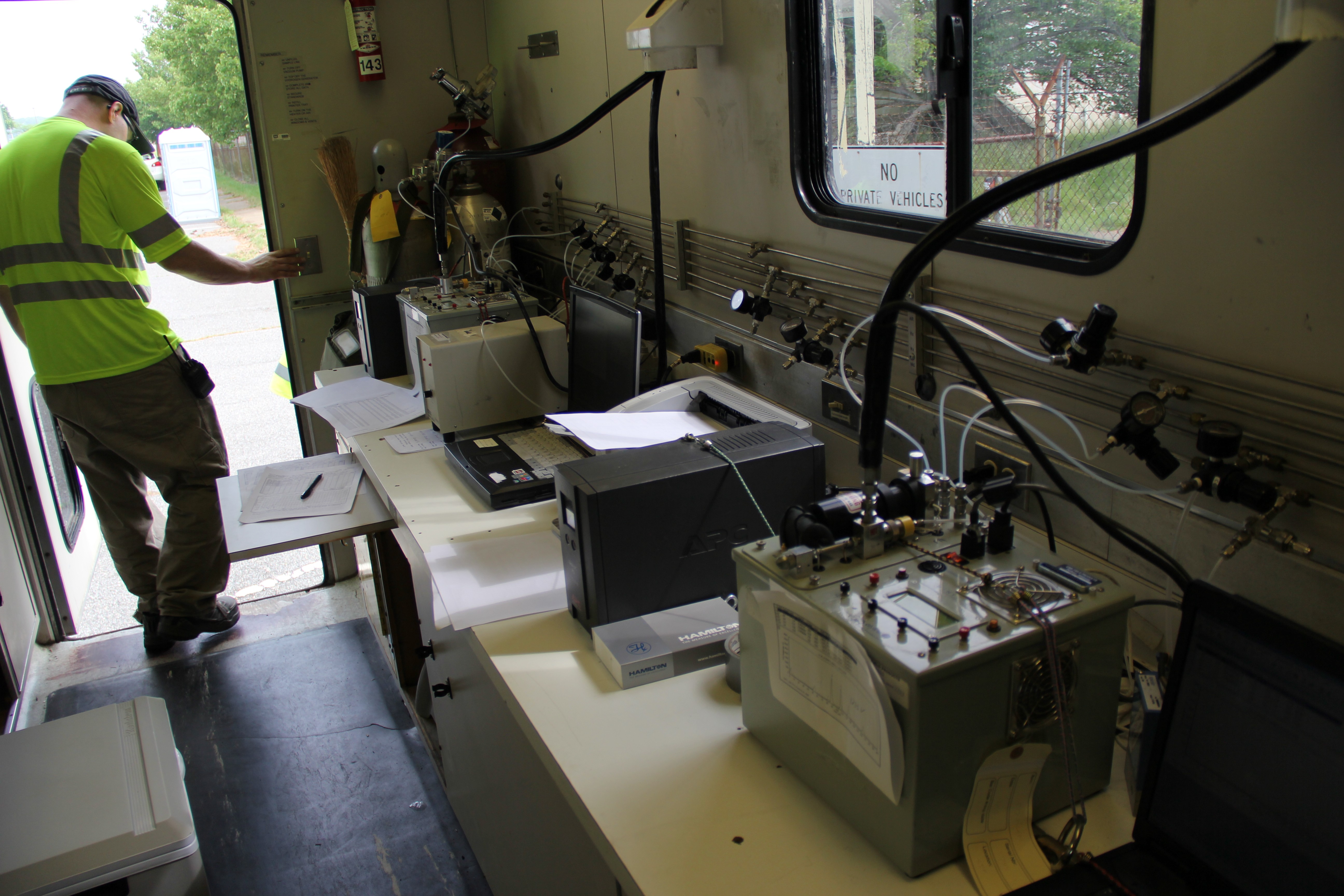

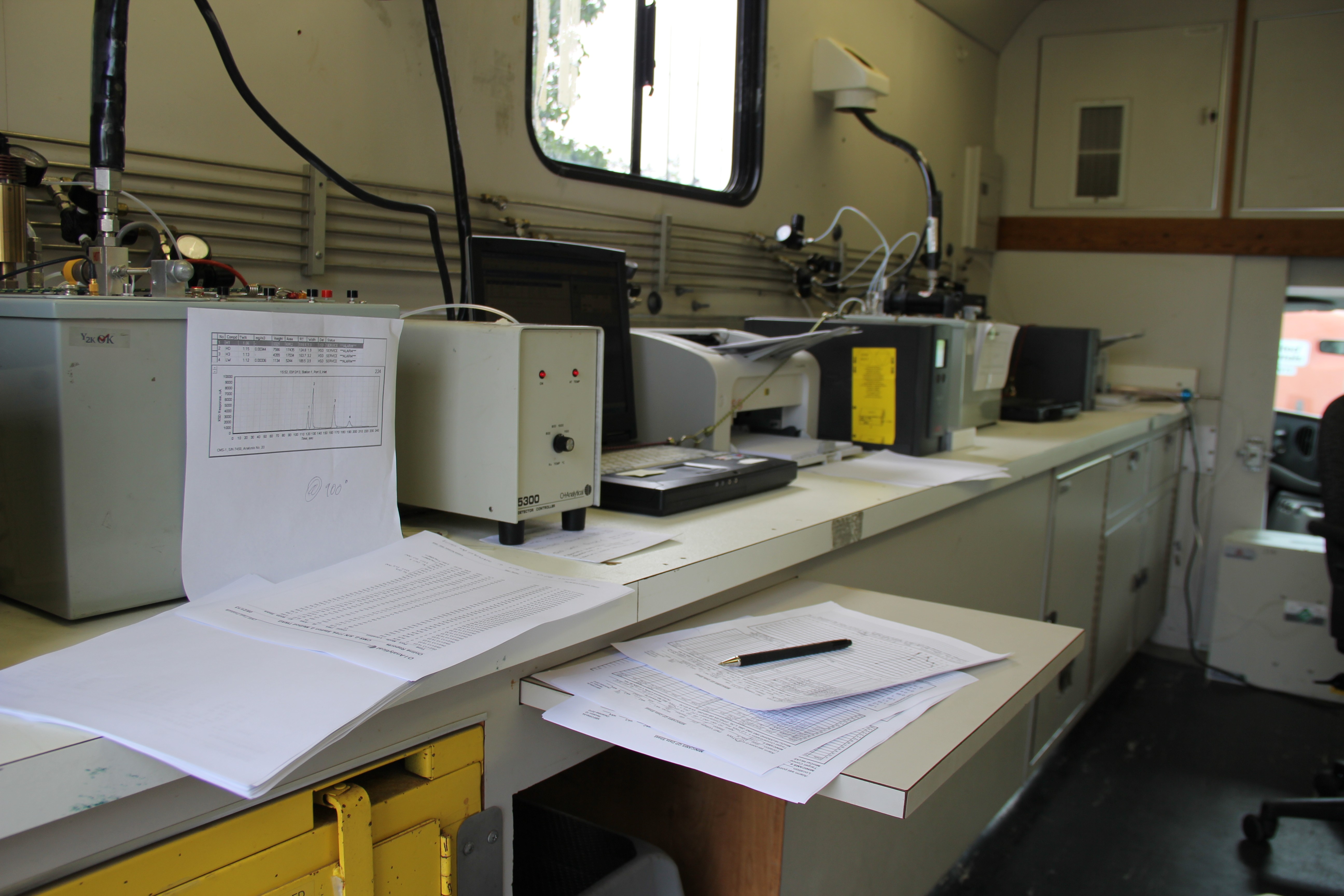

Parsons personnel wear personnel protective equipment to enter buildings and take surface samples, as well as soil and liquid samples from the buildings. Additionally, any unknown wastes in containers and drums are characterized in the buildings.

"These buildings have been abandoned for so long and are in such a state of disrepair that I think understanding the hazards and dangers of the work are paramount," Bruchey said.

A pre-operational survey was conducted with USAESCH, Parsons and ECBC personnel two weeks prior to operations to assess techniques, practices and protocols for the characterization work. The pre-operational exercises were designed to verify the Chemical Warfare Material Site Plan, familiarize all personnel with the operations and practice responses to potential scenarios. According to Bruchey, the project is expected to run through early July, where upon completion, the results from the sample analysis will help determine the future of the buildings.

A similar operation was completed by CBARR in 2007 on the E-3640 complex, where more than 150 wipe samples were collected and analyzed in support of the Chemical Materials Activity-Program Manager for Non-Stockpile Chemical Materiel. The effort resulted in building demolition and the dismantling of former surety agent equipment. At the time, the 11-month effort consisted of sampling, monitoring, dismantling, decontamination and disposal of potentially contaminated former surety agent process areas. As a result, ECBC demolished several smaller structures within the E3640 fence-line, including filtration and scrubber systems as well as storage and support structures.

In 2007, CBARR also completed a project that supported STEM International, Inc. in the decommissioning and decertifying of the Southern Research Institute Chemical Surety Laboratory in Birmingham, Ala. The three-month effort consisted of performing hazard review, risk analysis, sampling, monitoring, dismantling, decontamination and disposal of potentially contaminated former surety agent laboratories and equipment.

The SRI facility was approximately 2,500 square feet and located on the third floor of the westernmost wing of a five-story building. It consisted of five separate laboratories with nine chemical fume hoods, two roof ventilation fans, two sets of High Efficiency Particulate and charcoal filter banks, and associated ductwork. CBARR succeeded in safely dismantling and removing all process and laboratory equipment from the Chemical Surety Laboratories. No chemical agents of concern were detected during monitoring.

==============

ECBC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Related Links:

Army.mil: Science and Technology News

Social Sharing