PICATINNY ARSENAL, N.J. (May 29, 2013) -- Picatinny has formed a partnership with private industry to develop a fuel cell that runs off ethanol, which could potentially power the Army's ammunition facilities as an environmentally friendly energy source.

A fuel cell is an electrochemical device that converts a fuel source into electricity.

"The fuel cell technology would allow us to power ourselves separate from the electrical grid, which could be subject to storm damage or something like that, so we can continue to operate off of local power," explained Brian Meierdiercks, Program Management Engineer, with the Program Executive Office for Ammunition's Project Director Joint Services.

Additionally, because the fuel cell uses renewable energy, it helps to meet the Army's goal of reducing energy consumption. The Department of Defense is the world's largest consumer of energy.

"To meet a goal of 25 percent renewable energy by 2025, the Army must use every opportunity to be energy efficient and draw power from alternative and/or renewable energy sources," Secretary of the Army John McHugh said in 2011.

DERIVING ENERGY FROM CORN

The Army is researching the Iowa Army Ammunition Plant (IAAAP) in Middletown, Iowa, as the initial facility to test the prototype fuel cell technology. IAAAP produces medium- and large- caliber ammunition, such as tank ammunition.

Why IAAAP?

"Ethanol is derived from corn, which is abundant in Iowa," Meierdiercks explained.

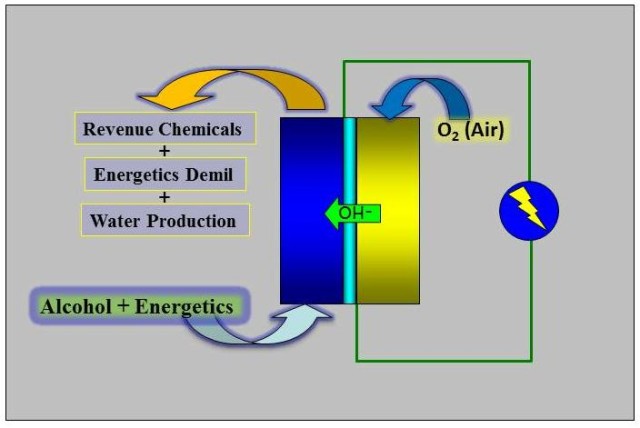

Besides serving as a green energy source, the fuel cell will have the additional benefit of using excess energetic waste as part of its fuel source. In the context of defense research, "energetics" is a short-hand term for materials such as explosives, propellants and pyrotechnics.

"During the ammunition manufacturing process there is always an energetic waste stream that is generated, and that has to be taken care of somehow," Meierdiercks said. "A lot of times its run through filters and the energetics are removed from the water. The fuel cell technology is actually able to take that energetic waste stream, run it through the fuel cell, and break down the energetic to provide additional power alongside the ethanol.

"Currently we have to pay either to have a system onsite, or pay someone off site to remove the energetic from the waste stream, so that's one cost we could avoid."

Savings derived from generating electricity and eliminating energetic waste could exceed $1 million a year at IAAAP alone.

"There will always be ethanol flowing through, and the ethanol will always be the majority of what's flowing through. We just add in our energetic waste stream as needed," Meierdiercks noted.

As an added bonus, chemicals that have an industrial use will be produced as a byproduct of the fuel cell process.

"Depending on how you operate the fuel cell, you can produce different byproducts, such as potassium acetate, which is used for de-icing airplanes and runways."

These chemicals could be sold to generate revenue and offset the costs of operating the fuel cell.

"Additionally, with a fuel cell, we would be producing our own electricity at a cost that is below the grid costs, which would mean more savings," Meierdiercks said.

PROVING THE TECHNOLOGY

The fuel cell technology that the Army is currently testing was developed by nanoMaterials Discovery Corporation (NDC).

Fuel cells work by breaking down a fuel source, in this case ethanol, using a chemical catalyst to release electrical energy. This electrical energy can replace or supplement the normal power from the electrical grid.

While fuel cells are common, the chemical catalyst in this particular fuel cell is unique because allows the destruction of energetic waste, as well as the production of useable industrial chemicals.

"The chemical combination they use is the 'secret sauce' if you will," Meierdiercks said.

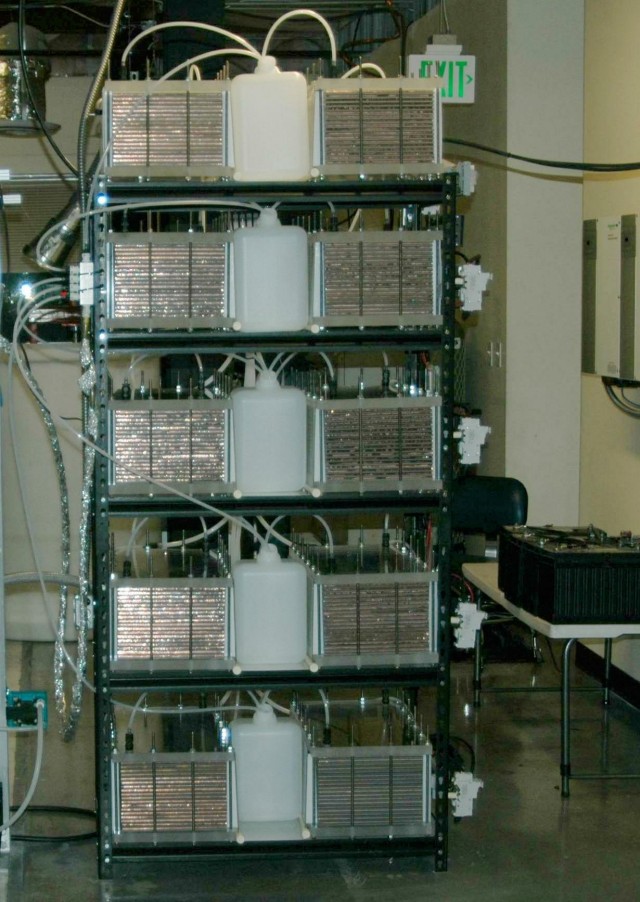

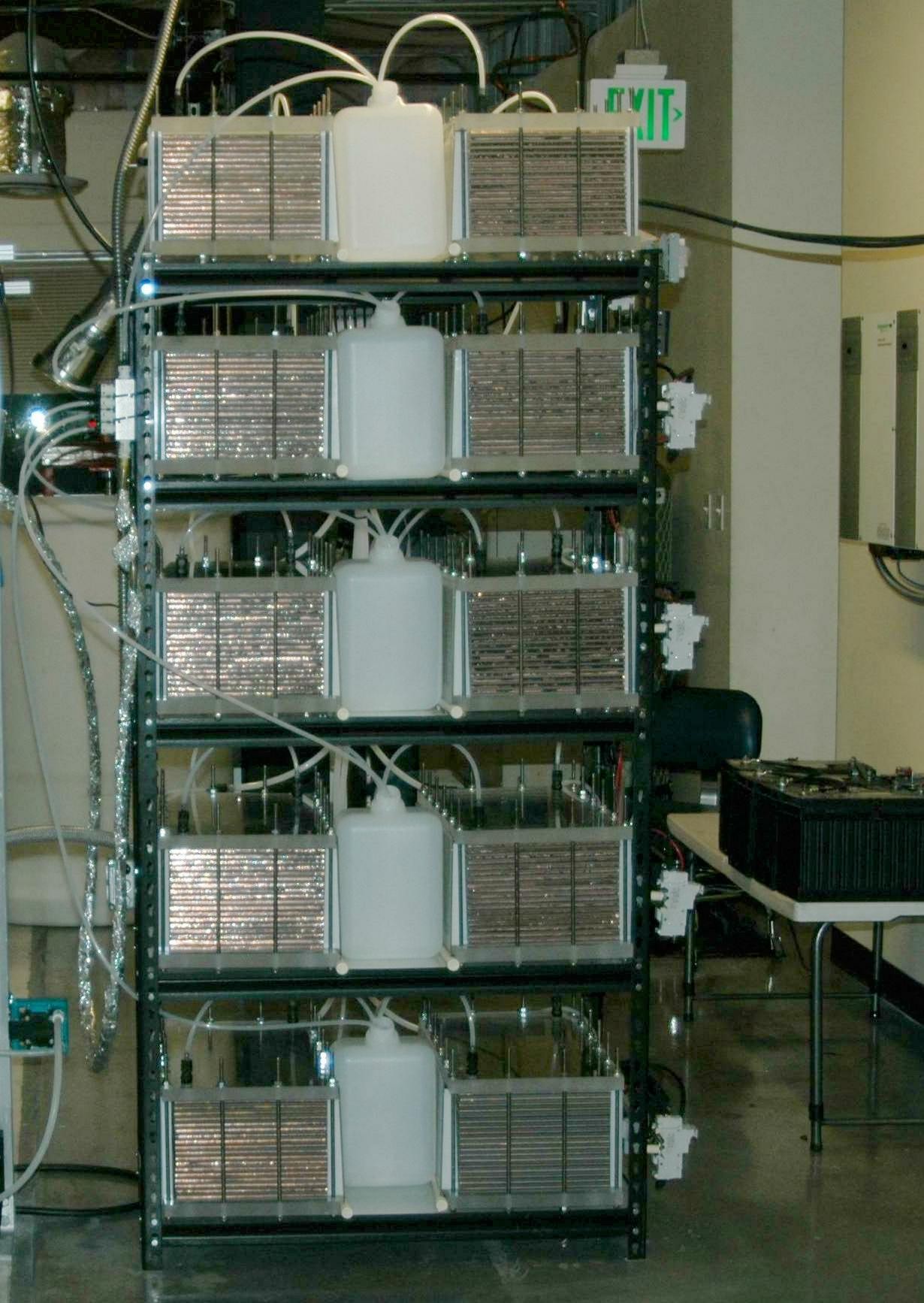

The NDC has created a 10 kilowatt prototype. Two megawatts would be needed at IAAAP.

"That seems like a big change, but the good news is that all you need to do is stack in more fuel cells," said Meierdiercks.

"So it's not like we're making what we've got larger, we're just making more of them. So if you can prove it out on a single stack then it will work on all these stacks and it's just a process of piping them all together."

If testing of the 10 kilowatt system yields positive results, IAAAP could be powered by this fuel cell technology in three to five years.

While Meierdiercks is optimistic about the technology, he remains cautious.

"We don't know if it's ultimately going to work -- this is research. We know it works at the small scale, and we're testing it at a larger level. We don't know if it will be able to power an entire facility."

Related Links:

Picatinny recycles artillery shells to create cheaper, safer, more realistic training rounds

PEO Ammunition captures prestigious DoD award

Energetic waste disposal can be a moving target

PGK arrives in Afghanistan ahead of fighting season

Fort Bragg first to receive upgraded M119 howitzers

Army.mil: Science & Technology

Social Sharing