WATERVLIET ARSENAL, N.Y. -- Arsenal machining apprentices are one step closer to becoming Department of the Army machinists as they presented their Capstone Project at a ceremony conducted this month at the Hudson Valley Community College in Troy, N.Y. The Capstone Project is the culmination of their schooling and a demonstration of their machining skills they have acquired in the four-year apprentice program.

The 14 arsenal apprentices have for the last four years attended a rigorous educational program at Hudson Valley that taught them how to draft blueprints to machining a finished product. While attending college, they were also working full time at the Watervliet Arsenal trying to amass 8,000 hours of hands-on training that is required for an apprentice to be considered for an entry-level journeyman machinist position at the Watervliet Arsenal.

Although the arsenal apprentice program began in 1905, its relationship with the community college began about 20 years ago.

Hudson Valley Professor David Larkin said during the ceremony that it took the class of 37 students more than 11,000 hours to design, machine, and assemble the final capstone project. The other students, some of them apprentices for local businesses such as General Electric, worked side-by-side the arsenal apprentices to produce 18 identical projects.

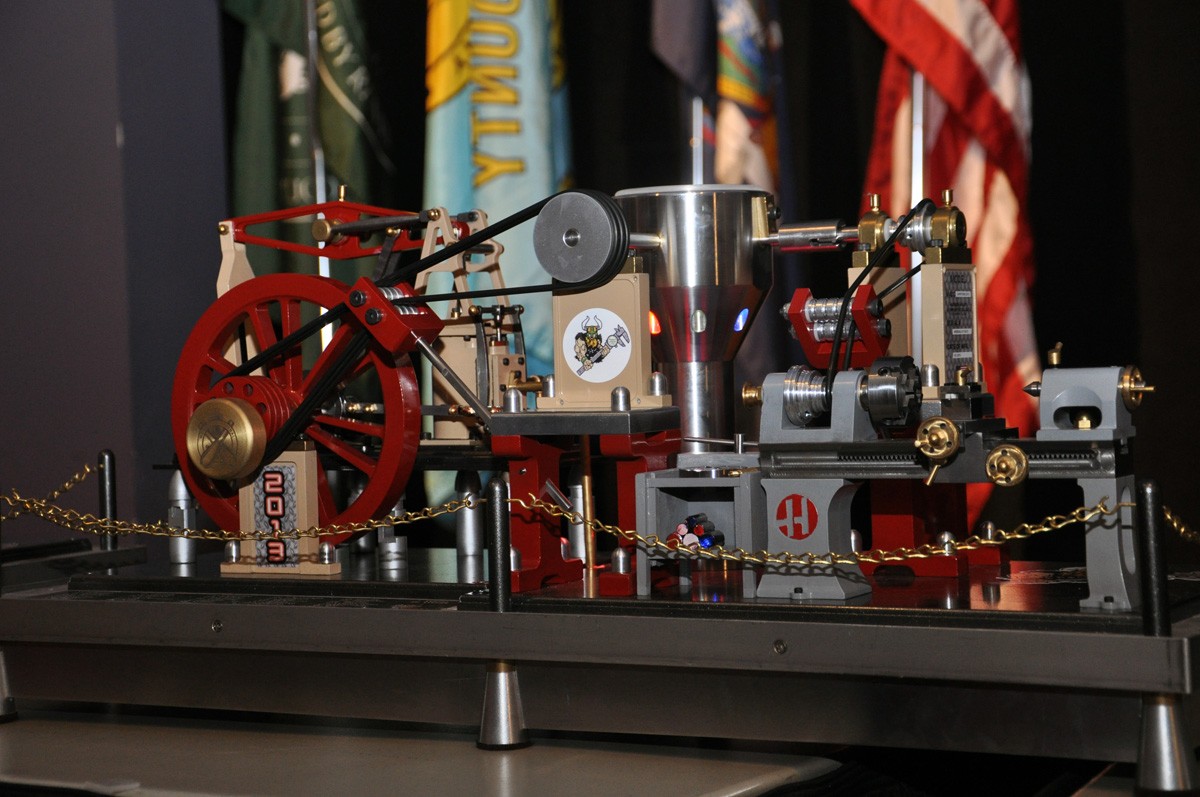

The project was a late 1800s-era, fully functional lathe complete with a steam engine, Larkin said. Each year, corporate sponsors provide the capstone project with seed money.

"When one totals the amount of work that the students put into the project, the return on the investment is a final product that is valued at approximately $70,000 that sponsors can showcase in their businesses," Larkin said.

Hudson Valley College President Drew Matonak said this was a great accomplishment and a true example of how much the college is committed to building up manufacturing in New York's Capital District.

"We may need to build a bigger stage because the gathering here today is absolutely incredible," Matonak said. "This is a tremendous program in that every one of the 37 students has a job or will have one soon."

Two of the arsenal's apprentices were recognized for their academic excellence.

Robert Fournier received the Blanchard Industrial Supplies Award for his selection as the top graduate, having maintained a 4.0 GPA.

"There wasn't one highlight of my four years because everything I did was a highlight," Fournier said of his apprentice experience. "This is a great opportunity for me and one that is personally satisfying because I will be machining the products that may save a Soldier's life."

Right behind Fournier in academic excellence was fellow arsenal apprentice Peter Northup, who also achieved a 4.0 GPA.

Northup said the apprentice program gave him an opportunity to learn how to machine on just about every one of the 600 machines at the arsenal.

"We started with manual-operated machines in our first couple of months and soon moved onto computer numerical controlled machines," Northup said.

This 82nd class of arsenal apprentices began their training nearly four years ago and since then have been working full time at the arsenal while also putting in another 10-20 hours a week for their college studies.

The students graduated from Hudson Valley this month and will complete their 8,000 hours of hands-on training this summer at the arsenal. They will officially graduate from the apprentice program in August. Upon graduation, they will receive a certificate from the Department of Labor saying that they are journeyman machinists.

Arsenal apprentices in 1905 dealt with chalk boards - today's apprentices deal with high-tech smart boards.

Apprentices in 1905 dealt with mud on the streets of Watervliet as they walked their way to work - today's apprentices deal with I-787, I-87, and I-90.

Apprentices in 1905 dealt with steel that was not much better than flake iron - today's apprentices must deal with hardened Titanium and Inconel steel.

Finally, apprentices in 1905 dealt with competition from manufacturers mainly in the Northeast - today's apprentices must deal with global competition.

The Watervliet Arsenal (pronounced water-vleet") is an Army-owned-and-operated manufacturing facility located in Watervliet, New York. The Arsenal is the oldest, continuously active arsenal in the United States, having begun operations during the War of 1812. It will celebrate its 200th anniversary on July 14, 2013.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high tech, high powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $100 million.

Complete listing of arsenal apprentices:

Altenos, John

Bashford, William

Boak, Timothy

Chirpka, Kenneth

Day, Robert

Delisle, Robert

Fontaine, Timothy

Fournier, Robert

Kusaywa, Dylan (Completed his studies at Hudson Valley last summer)

McCarthy, William

Northup, Peter

Smith, Jared

Weishaar, John

Wert, Brant

White, James

Related Links:

Watervliet Arsenal Twitter Page

Army wins SecArmy safety award

Watervliet Arsenal Flickr Page

Watervliet Arsenal Newsletters via Slideshare

Social Sharing